Model SB1029 | E L E C T R I C A L | For Machines Mfg. Since 8/09 |

Rewiring for 440V | 6 | 7 | 0 | U | V | W | U1 | V1 | W1 | R | S | T | |

Wiring diagrams are provided in this section | 6 | 7 | 0 | U | V | W | U1 | V1 | W1 | R | S | T | |

showing the Model SB1029 wired for both 220V | |||||||||||||

|

|

|

|

|

|

|

|

|

|

| GND | ||

and 440V. Refer to these diagrams if needed |

|

|

|

|

|

|

|

|

|

|

| ||

when following this procedure. Additionally, |

|

| 0 | U | V | W |

|

|

| R | S | T | |

|

|

|

|

|

|

|

|

|

|

|

| ||

you must purchase 440V Conversion Kit (Part |

|

|

|

|

|

|

|

|

|

|

|

| |

No. PSB1029510) in order to complete the |

|

|

|

|

|

|

|

|

|

|

|

| |

conversion. |

|

|

|

|

|

|

|

|

|

|

|

|

Hardwiring to Power Source | Incoming |

Power Cord |

Hardwire setups require power supply lines to |

|

|

|

|

| ||||

be enclosed inside of conduit that is securely |

| Figure 52. Power connection wiring. | |||||||

mounted and constructed in adherence to |

| ||||||||

applicable electrical codes. |

|

| Items Needed |

|

| Qty. | |||

|

|

|

|

|

| ||||

A hardwire setup for this machine must be | 440V Conversion Kit (Part No. PSB1029510) ..... 1 | ||||||||

equipped with a locking disconnect switch | Phillips Screwdriver #2 ........................................ 1 | ||||||||

as a means to disconnect the power during | To convert the Model SB1029 to operate on | ||||||||

adjustments or maintenance, which is a typical | |||||||||

requirement for | 440V: |

|

|

| |||||

(commonly required by OSHA). Figure 13 shows | 1. DISCONNECT MACHINE FROM POWER! | ||||||||

a simple diagram of a hardwire setup with a | |||||||||

|

|

|

|

| |||||

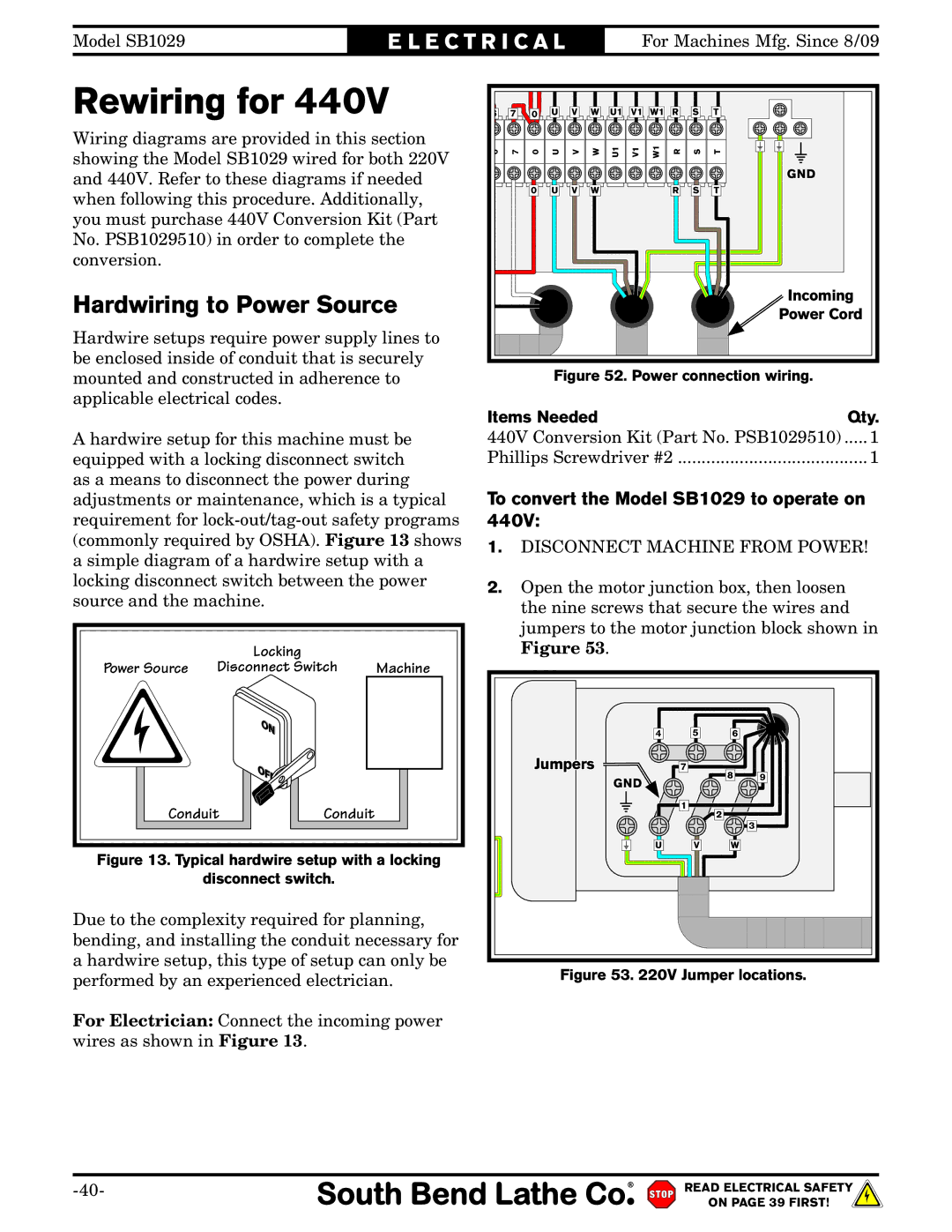

locking disconnect switch between the power | 2. | Open the motor junction box, then loosen | |||||||

source and the machine. |

|

| |||||||

|

|

| the nine screws that secure the wires and | ||||||

|

|

|

|

| |||||

|

|

|

|

| jumpers to the motor junction block shown in | ||||

| Locking |

|

|

| Figure 53. |

|

|

| |

Power Source | Disconnect Switch | Machine |

| oto |

|

|

| ||

|

|

|

|

| 4 | 5 | 6 |

| |

|

|

|

|

| Jumpers | 7 | 8 | 9 | |

|

|

|

|

| GND |

| |||

|

|

|

|

|

|

|

| ||

Conduit | Conduit |

|

|

| 1 | 2 |

| ||

|

|

|

| 3 | |||||

|

|

|

|

|

|

|

| ||

Figure 13. Typical hardwire setup with a locking |

| U | V | W |

| ||||

|

|

|

|

| |||||

| disconnect switch. |

|

|

|

|

|

| ||

Due to the complexity required for planning, |

|

bending, and installing the conduit necessary for |

|

a hardwire setup, this type of setup can only be | Figure 53. 220V Jumper locations. |

performed by an experienced electrician. |

For Electrician: Connect the incoming power wires as shown in Figure 13.

READ ELECTRICAL SAFETY | |

| ON PAGE 39 FIRST! |