Model SB1029 | O P E R A T I O N | For Machines Mfg. Since 8/09 |

Wheel Dressing

Superior grinding results can only be achieved with a properly balanced and dressed wheel. Do not assume that a wheel will run true on the spindle if it is new or has not been separated from the hub.

Dressing the wheel correctly will save you from wasting grinding abrasive and shattering the dressing tool diamond. Additionally, with a properly balanced and dressed wheel you can rest assured that if you have finish problems, the grinding wheel will not be the culprit.

Depending on the finish required, varying degrees of roughness can be obtained. For example: A fast dressing at a depth of 0.03mm will prepare a wheel surface for rough cuts, and slow dressing with multiple light passes at a depth of 0.01mm will prepare the same wheel for finish cuts.

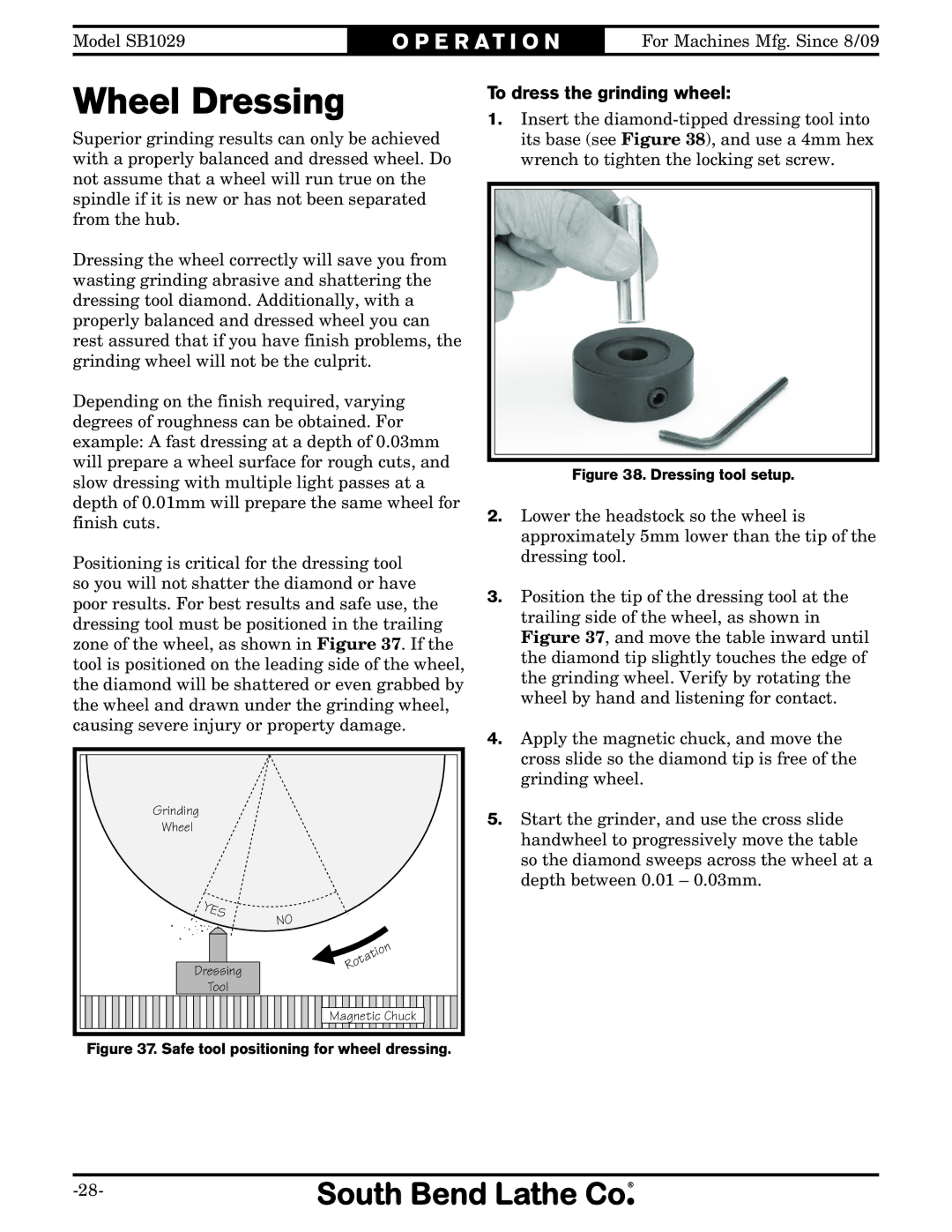

Positioning is critical for the dressing tool so you will not shatter the diamond or have poor results. For best results and safe use, the dressing tool must be positioned in the trailing zone of the wheel, as shown in Figure 37. If the tool is positioned on the leading side of the wheel, the diamond will be shattered or even grabbed by the wheel and drawn under the grinding wheel, causing severe injury or property damage.

Grinding

Wheel

YES | NO |

|

Dressing | Rotation |

| |

Tool |

|

| Magnetic Chuck |

Figure 37. Safe tool positioning for wheel dressing.

To dress the grinding wheel:

1.Insert the

Figure 38. Dressing tool setup.

2.Lower the headstock so the wheel is approximately 5mm lower than the tip of the dressing tool.

3.Position the tip of the dressing tool at the trailing side of the wheel, as shown in Figure 37, and move the table inward until the diamond tip slightly touches the edge of the grinding wheel. Verify by rotating the wheel by hand and listening for contact.

4.Apply the magnetic chuck, and move the cross slide so the diamond tip is free of the grinding wheel.

5.Start the grinder, and use the cross slide handwheel to progressively move the table so the diamond sweeps across the wheel at a depth between 0.01 – 0.03mm.