Model SB1029 | M A I N T E N A N C E | For Machines Mfg. Since 8/09 |

—If the pinions or leadscrew show a buildup of contaminants, clean them with mineral spirits and

—If the pinions or leadscrew are dry, verify that the pump screen is clean, and adjust the oil distribution screw to increase lubrication.

4.At the rear of the column, slide the column dust shield upward and inspect the upper leadscrew (see Figure 46).

Figure 46. Upper leadscrew inspection.

—If the leadscrew has a buildup of contaminants, clean it with mineral spirits and

—If the leadscrew is dry, verify that the pump screen is clean, and adjust the oil distribution screw to increase lubrication.

5.Using a rust preventative oil, wipe down all bare metal surfaces.

6.Using any quality automotive paint cleaner and wax, clean and wax all painted surfaces.

Changing Oil & Adjusting Oil Flow

This machine is equipped with a pressurized

In heavy industrial or dirty environments, change this oil more frequently. To avoid oil breakdown, DO NOT MIX OILS! If changing oil types, be sure to flush the system with the new oil and discard the flushed oil.

Recommended Oils:

ssMobil Vacuoline 1405 ss Mobil Vacuoline 1409 ss Shell Tonna 33

ss Shell Tonna 27

ss BP Energol HP

To change the oil and adjust the flow rate:

1.DISCONNECT MACHINE FROM POWER.

2.Remove the panel from the rear of the cabinet.

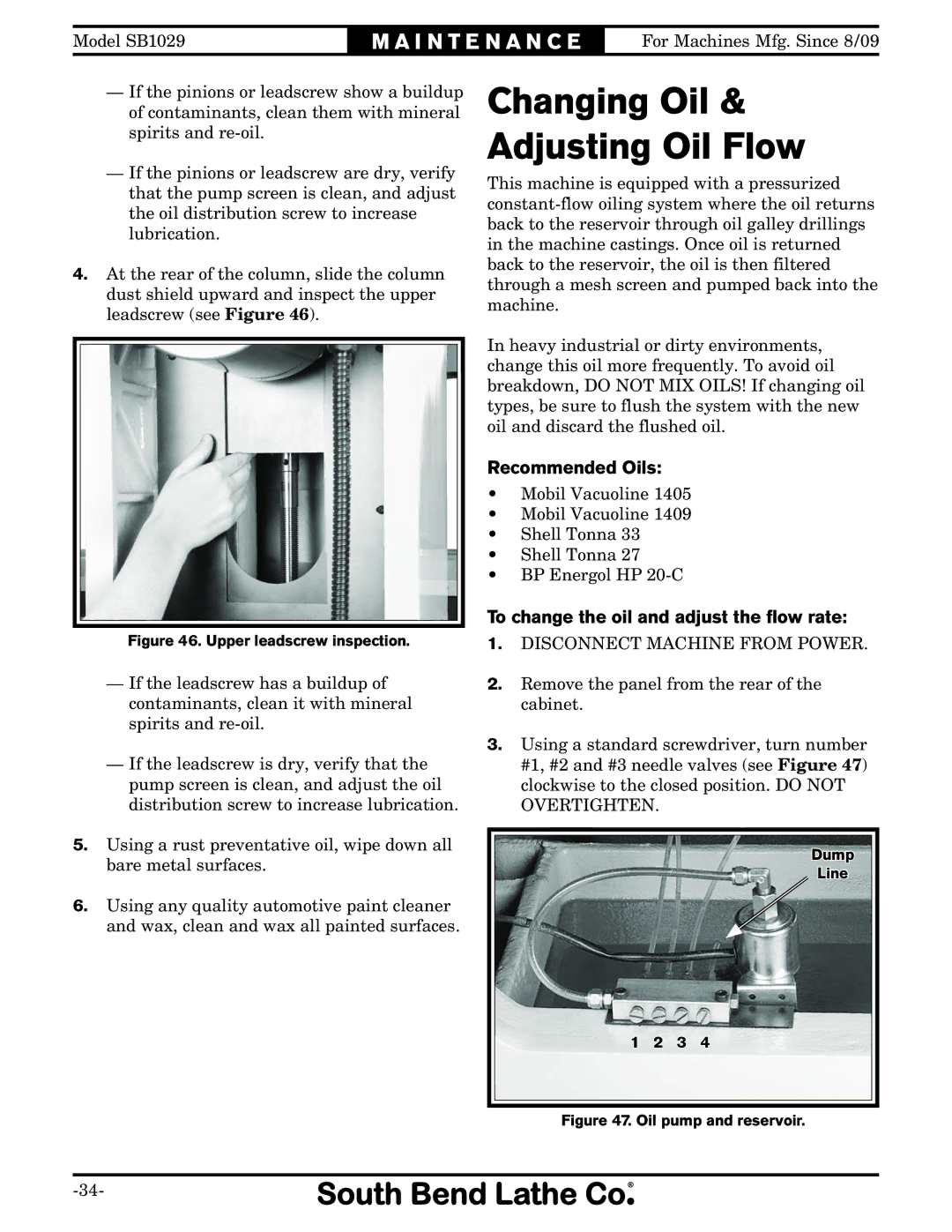

3.Using a standard screwdriver, turn number #1, #2 and #3 needle valves (see Figure 47) clockwise to the closed position. DO NOT OVERTIGHTEN.

Dump

Line

1 2 3 4