14" | O P E R A T I O N | For Machines Mfg. Since 5/11 |

|

|

|

3.The configuration string of characters to the right of the selected feed rate (LCS8W) displays the positions to set the feed controls for a feed rate of 0.18mm/rev. (see Figure 72).

Note: In the next step, use the chuck key to rock the spindle back and forth to help mesh the gears as you make adjustments.

4.Position the controls as directed by the configuration string as follows (see Figure 73):

L:Move the feed range lever to the low (Low) position.

C:Point the left

S:Move the middle

8:Position the bottom gearbox lever in the 8 slot.

W:Point the right gearbox lever to the W.

.050 LCT1W .002

.055 LCT2W .0022

.065 LCT4W .003

.085 LCT8W .0033

.10 LCS2W .004

.13 LCS4W .005

.18 LCS8W .007

.22 LCR3W .009

.28 LCR4W .011

.35 LCR8W .014

Figure 73. Power feed controls positioned for

0.18 mm/rev.

The lathe is now set up for a power feed rate of 0.18mm per spindle revolution.

End Gears

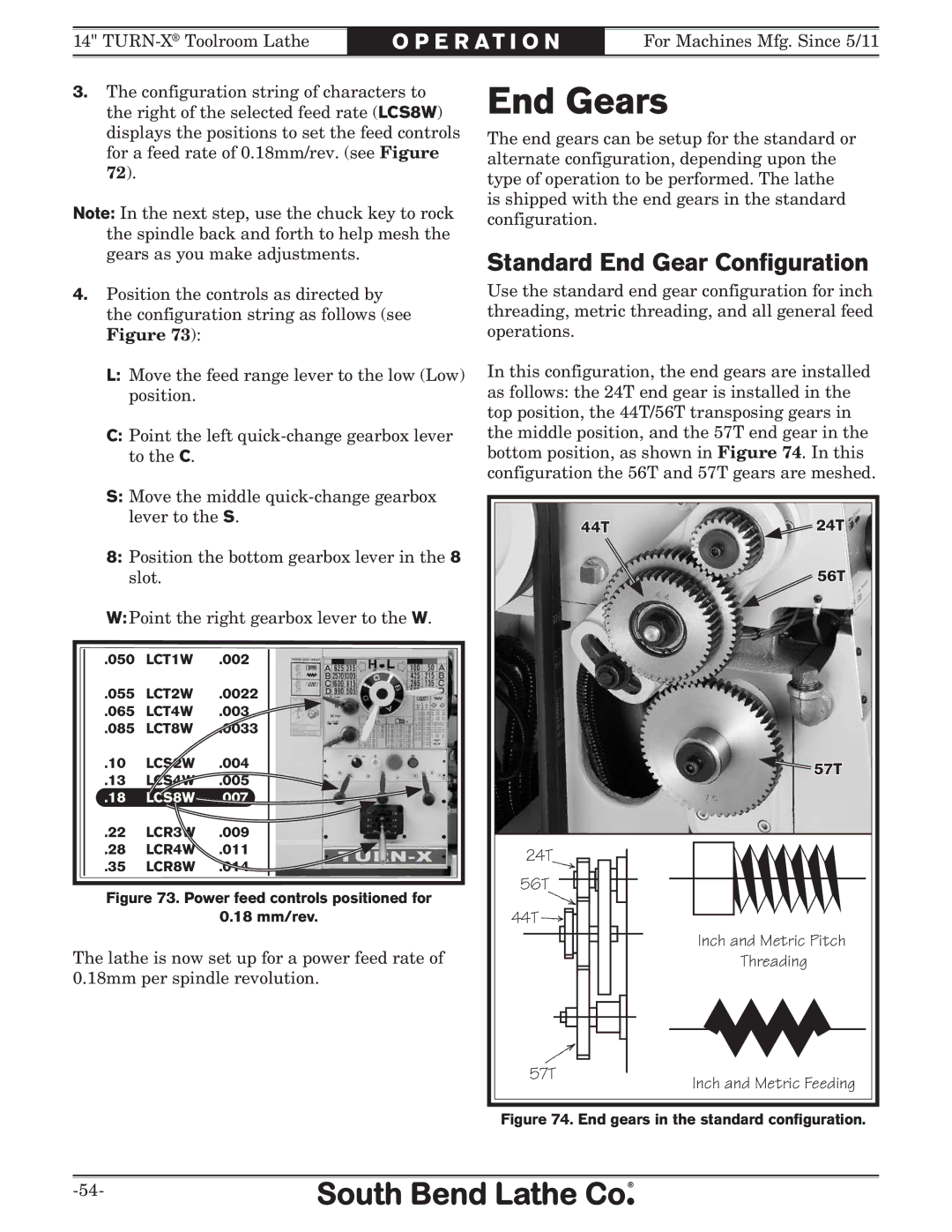

The end gears can be setup for the standard or alternate configuration, depending upon the type of operation to be performed. The lathe is shipped with the end gears in the standard configuration.

Standard End Gear Configuration

Use the standard end gear configuration for inch threading, metric threading, and all general feed operations.

In this configuration, the end gears are installed as follows: the 24T end gear is installed in the top position, the 44T/56T transposing gears in the middle position, and the 57T end gear in the bottom position, as shown in Figure 74. In this configuration the 56T and 57T gears are meshed.

44T | 24T |

| 56T |

| 57T |

24T |

|

56T |

|

44T |

|

| Inch and Metric Pitch |

| Threading |

57T | Inch and Metric Feeding |

|