14" | I N T R O D U C T I O N | For Machines Mfg. Since 5/11 |

|

|

|

Control Panel

I J

H![]()

![]()

![]()

![]() K

K

Figure 5. Control panel.

H.Coolant Pump Switch: Controls the coolant pump motor.

I.Power Light: Illuminates when lathe controls are receiving power.

J.STOP Button: Stops all machine functions. Twist clockwise to reset.

K.Jog Button: Starts forward spindle rotation as long as it is pressed.

Carriage |

|

|

| |

| L |

|

| N |

|

| M |

| |

|

|

|

| |

|

| O |

| P |

|

|

|

| |

| X |

|

|

|

| W |

|

| Q |

|

|

|

| |

V | U | T | S | R |

|

|

| ||

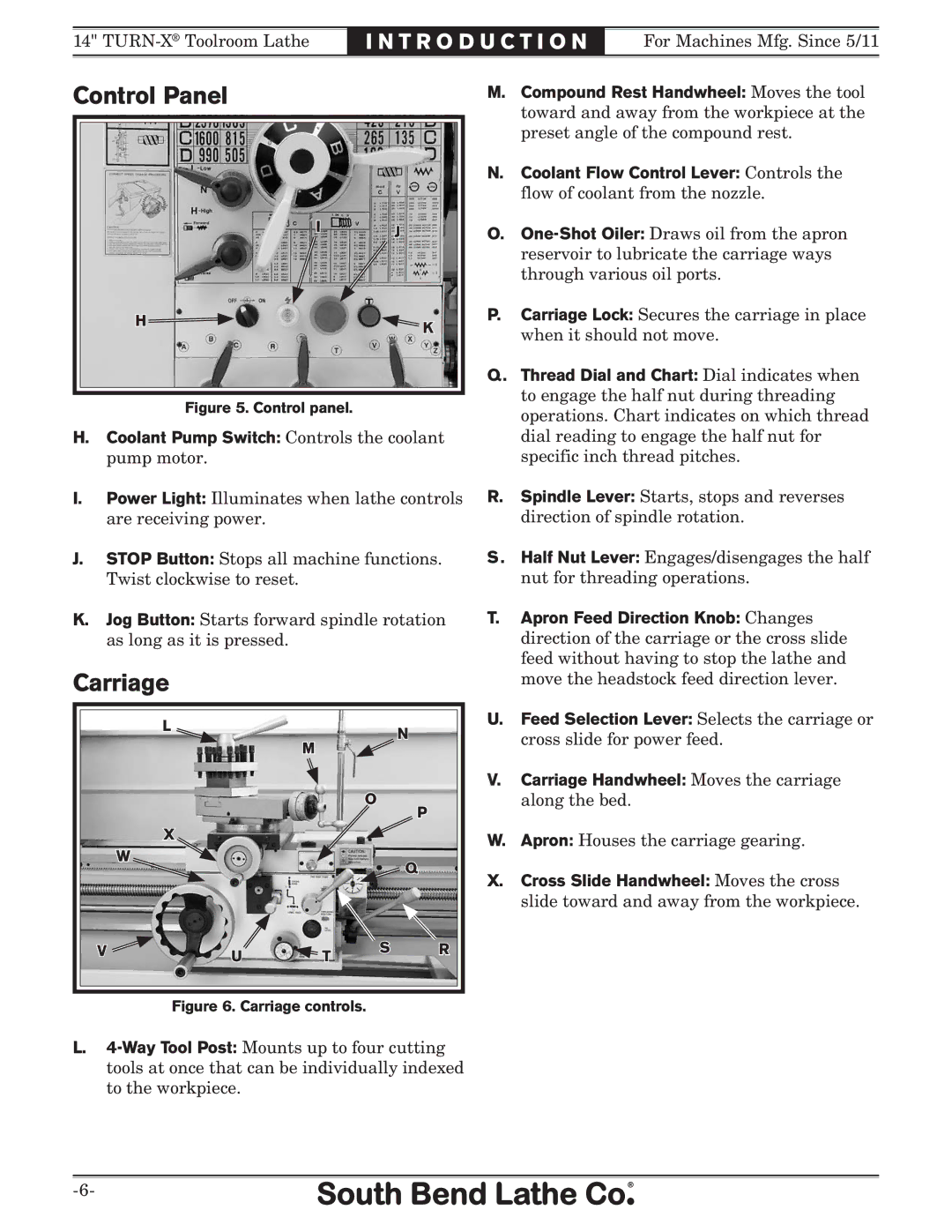

| Figure 6. Carriage controls. |

|

| |

L.

M.Compound Rest Handwheel: Moves the tool toward and away from the workpiece at the preset angle of the compound rest.

N.Coolant Flow Control Lever: Controls the flow of coolant from the nozzle.

O.

P.Carriage Lock: Secures the carriage in place when it should not move.

Q . Thread Dial and Chart: Dial indicates when to engage the half nut during threading operations. Chart indicates on which thread dial reading to engage the half nut for specific inch thread pitches.

R.Spindle Lever: Starts, stops and reverses direction of spindle rotation.

S . Half Nut Lever: Engages/disengages the half nut for threading operations.

T.Apron Feed Direction Knob: Changes direction of the carriage or the cross slide feed without having to stop the lathe and move the headstock feed direction lever.

U.Feed Selection Lever: Selects the carriage or cross slide for power feed.

V.Carriage Handwheel: Moves the carriage along the bed.

W.Apron: Houses the carriage gearing.

X.Cross Slide Handwheel: Moves the cross slide toward and away from the workpiece.