For Machines Mfg. Since 5/11 | P R E P A R A T I O N | 14" |

|

|

|

3.Clear away all tools and objects used during assembly, lubrication, and preparation.

4.Make sure that the chuck and jaws, if installed, are secure (refer to Chuck and Faceplate Mounting on Page 32).

Note: If a chuck is not installed on the lathe, you do not need to install one for this test.

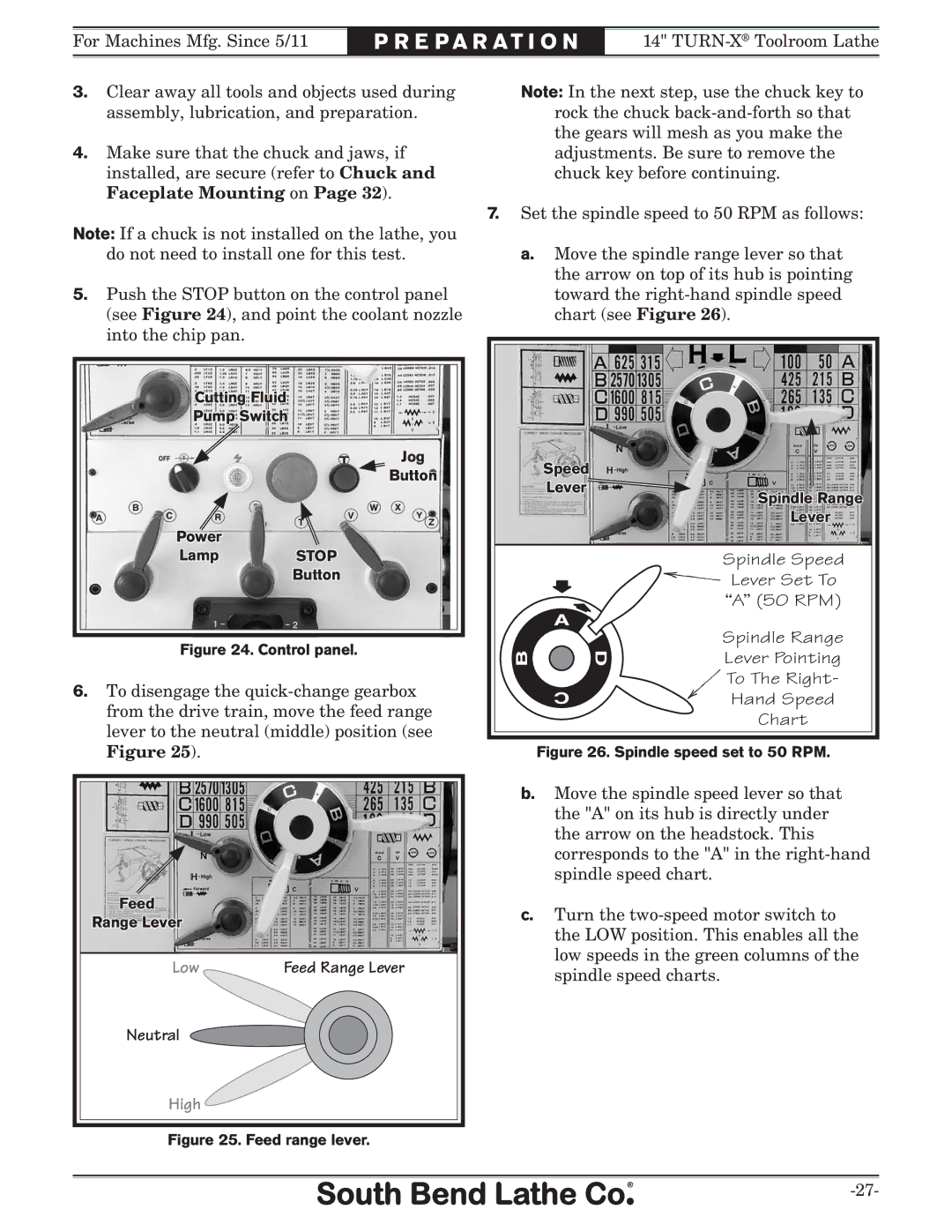

5.Push the STOP button on the control panel (see Figure 24), and point the coolant nozzle into the chip pan.

Cutting Fluid

Pump Switch

Jog

Button

Power

Lamp STOP

Button

Figure 24. Control panel.

6.To disengage the

Feed

Range Lever

Low | Feed Range Lever |

Neutral

High

Figure 25. Feed range lever.

Note: In the next step, use the chuck key to rock the chuck

7.Set the spindle speed to 50 RPM as follows:

a.Move the spindle range lever so that the arrow on top of its hub is pointing toward the

Speed |

|

Lever | Spindle Range |

| |

| Lever |

| Spindle Speed |

| Lever Set To |

| “A” (50 RPM) |

A

Spindle Range

B | D | Lever Pointing |

|

| To The Right- |

| C | Hand Speed |

|

| Chart |

Figure 26. Spindle speed set to 50 RPM.

b.Move the spindle speed lever so that the "A" on its hub is directly under the arrow on the headstock. This corresponds to the "A" in the

c.Turn the

spindle speed charts.