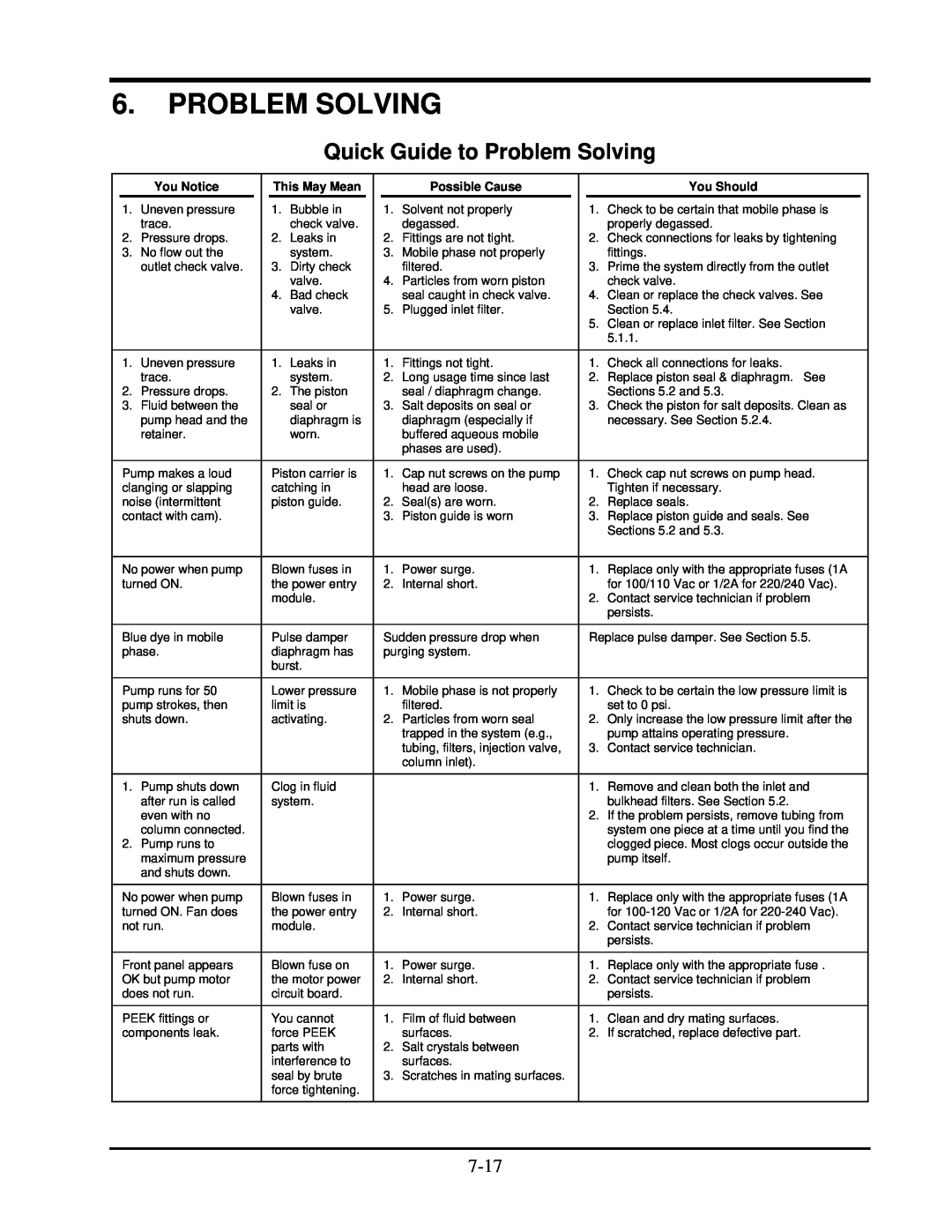

6.PROBLEM SOLVING

Quick Guide to Problem Solving

| You Notice | This May Mean |

| Possible Cause | |

1. | Uneven pressure | 1. | Bubble in | 1. | Solvent not properly |

| trace. |

| check valve. |

| degassed. |

2. | Pressure drops. | 2. | Leaks in | 2. | Fittings are not tight. |

3. No flow out the |

| system. | 3. | Mobile phase not properly | |

| outlet check valve. | 3. | Dirty check |

| filtered. |

|

|

| valve. | 4. | Particles from worn piston |

|

| 4. | Bad check |

| seal caught in check valve. |

|

|

| valve. | 5. | Plugged inlet filter. |

1. | Uneven pressure | 1. | Leaks in | 1. | Fittings not tight. |

| trace. |

| system. | 2. | Long usage time since last |

2. | Pressure drops. | 2. | The piston |

| seal / diaphragm change. |

3. | Fluid between the |

| seal or | 3. | Salt deposits on seal or |

| pump head and the |

| diaphragm is |

| diaphragm (especially if |

| retainer. |

| worn. |

| buffered aqueous mobile |

|

|

|

|

| phases are used). |

Pump makes a loud | Piston carrier is | 1. | Cap nut screws on the pump | ||

clanging or slapping | catching in |

| head are loose. | ||

noise (intermittent | piston guide. | 2. | Seal(s) are worn. | ||

contact with cam). |

|

| 3. | Piston guide is worn | |

No power when pump | Blown fuses in | 1. | Power surge. | ||

turned ON. | the power entry | 2. | Internal short. | ||

|

| module. |

|

| |

Blue dye in mobile | Pulse damper | Sudden pressure drop when | |||

phase. | diaphragm has | purging system. | |||

|

| burst. |

|

| |

Pump runs for 50 | Lower pressure | 1. | Mobile phase is not properly | ||

pump strokes, then | limit is |

| filtered. | ||

shuts down. | activating. | 2. | Particles from worn seal | ||

|

|

|

|

| trapped in the system (e.g., |

|

|

|

|

| tubing, filters, injection valve, |

|

|

|

|

| column inlet). |

1. | Pump shuts down | Clog in fluid |

|

| |

| after run is called | system. |

|

| |

| even with no |

|

|

|

|

| column connected. |

|

|

|

|

2.Pump runs to maximum pressure and shuts down.

No power when pump | Blown fuses in | 1. | Power surge. |

turned ON. Fan does | the power entry | 2. | Internal short. |

not run. | module. |

|

|

Front panel appears | Blown fuse on | 1. | Power surge. |

OK but pump motor | the motor power | 2. | Internal short. |

does not run. | circuit board. |

|

|

PEEK fittings or | You cannot | 1. | Film of fluid between |

components leak. | force PEEK |

| surfaces. |

| parts with | 2. | Salt crystals between |

| interference to |

| surfaces. |

| seal by brute | 3. | Scratches in mating surfaces. |

| force tightening. |

|

|

You Should

1.Check to be certain that mobile phase is properly degassed.

2.Check connections for leaks by tightening fittings.

3.Prime the system directly from the outlet check valve.

4.Clean or replace the check valves. See Section 5.4.

5.Clean or replace inlet filter. See Section 5.1.1.

1.Check all connections for leaks.

2.Replace piston seal & diaphragm. See Sections 5.2 and 5.3.

3.Check the piston for salt deposits. Clean as necessary. See Section 5.2.4.

1.Check cap nut screws on pump head. Tighten if necessary.

2.Replace seals.

3.Replace piston guide and seals. See Sections 5.2 and 5.3.

1.Replace only with the appropriate fuses (1A for 100/110 Vac or 1/2A for 220/240 Vac).

2.Contact service technician if problem persists.

Replace pulse damper. See Section 5.5.

1.Check to be certain the low pressure limit is set to 0 psi.

2.Only increase the low pressure limit after the pump attains operating pressure.

3.Contact service technician.

1.Remove and clean both the inlet and bulkhead filters. See Section 5.2.

2.If the problem persists, remove tubing from system one piece at a time until you find the clogged piece. Most clogs occur outside the pump itself.

1.Replace only with the appropriate fuses (1A for

2.Contact service technician if problem persists.

1.Replace only with the appropriate fuse .

2.Contact service technician if problem persists.

1.Clean and dry mating surfaces.

2.If scratched, replace defective part.