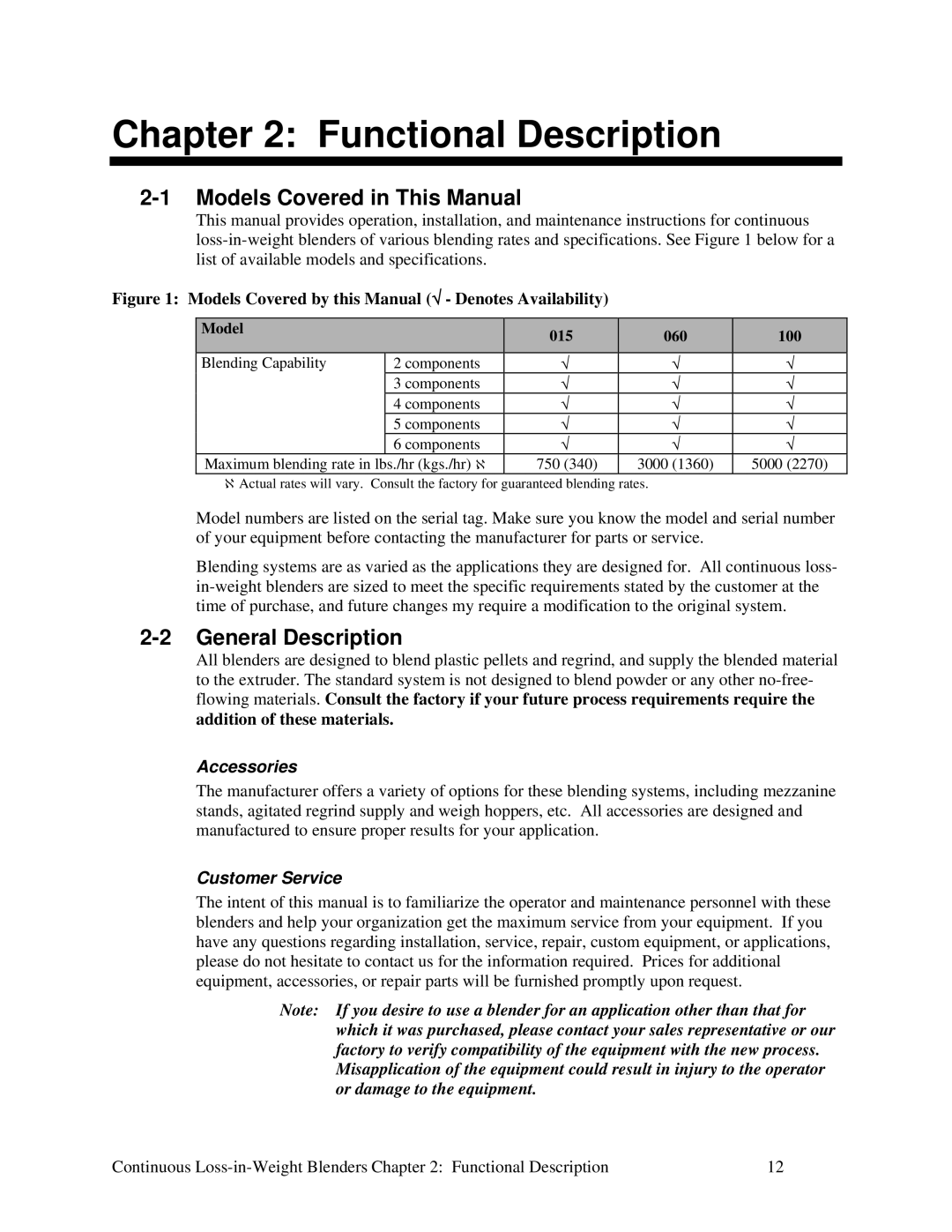

060, SLC 5/04, 015, 600, 100 specifications

Sterling 100,600,015 SLC 5/04,060 is a robust and versatile industrial automation controller designed to meet the demands of various industrial applications. As part of the Sterling lineup, this model is particularly known for its reliability and advanced features that enhance operational efficiency.One of the main features of the Sterling 100,600,015 SLC 5/04,060 is its modular architecture, which allows users to customize the system based on their specific needs. The controller supports a wide range of I/O modules, providing flexibility in expanding or modifying the system as production requirements change. This modularity ensures scalability, making it suitable for both small-scale and large-scale applications.

The controller operates on the well-established Allen-Bradley SLC 500 platform, which is known for its stability and ease of use. With a processing speed of 100 kHz, the SLC 5/04,060 can handle multiple tasks simultaneously, ensuring precise control over processes. This speed is complemented by a large memory capacity, allowing for complex programming and data storage without compromising performance.

In terms of communication, the Sterling 100,600,015 SLC 5/04,060 features multiple communication ports, including RS-232 and RS-485 interfaces, making it compatible with various devices and systems. This capability enables seamless integration with existing networks, as well as the implementation of modern network protocols like Ethernet for greater connectivity and data transfer efficiency.

The controller is also equipped with advanced diagnostics capabilities, enabling users to monitor system performance in real-time. This feature not only helps in quick troubleshooting but also aids in predictive maintenance strategies, reducing downtime and optimizing productivity.

In addition to its hardware features, the Sterling 100,600,015 SLC 5/04,060 supports a range of programming languages, including ladder logic, structured text, and function block diagrams. This versatility allows engineers and technicians to choose the most suitable approach for their specific projects, making the development process more intuitive and efficient.

Overall, the Sterling 100,600,015 SLC 5/04,060 is a powerful and adaptable solution for industrial automation, combining advanced technology with ease of use, making it an ideal choice for businesses seeking to enhance their operational capabilities and efficiency.