2.2 Pneumatic Connections

1.Connect a ¼” exhaust line to the fitting labeled ‘Exhaust.’ This line should be vented to an outside area, since the exhaust gas may still contain trace levels of ozone that may not be completely removed by the

CAUTION

Exhaust gas from the M460H may contain dangerous levels of

ozone!

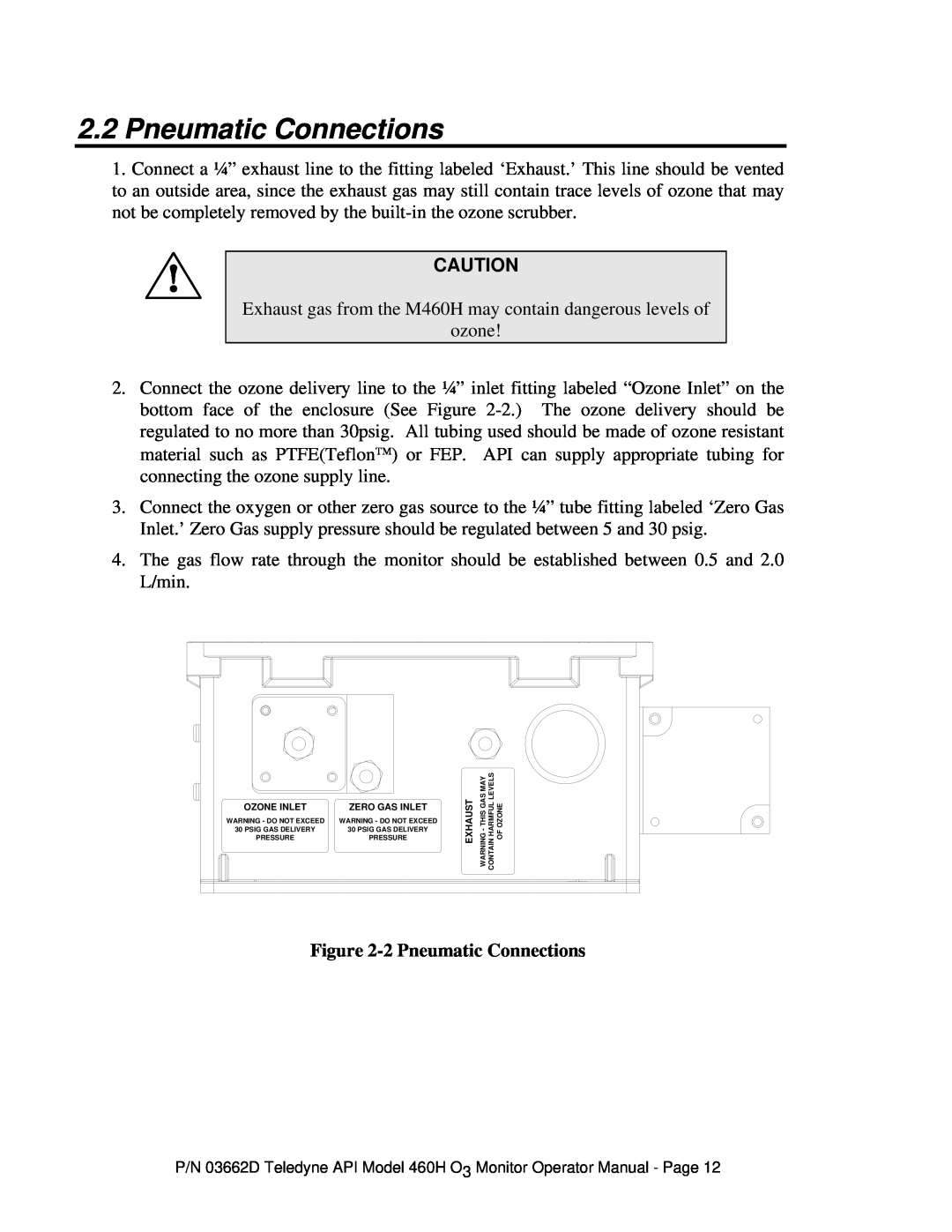

2.Connect the ozone delivery line to the ¼” inlet fitting labeled “Ozone Inlet” on the bottom face of the enclosure (See Figure

3.Connect the oxygen or other zero gas source to the ¼” tube fitting labeled ‘Zero Gas Inlet.’ Zero Gas supply pressure should be regulated between 5 and 30 psig.

4.The gas flow rate through the monitor should be established between 0.5 and 2.0 L/min.

OZONE INLET | ZERO GAS INLET |

WARNING - DO NOT EXCEED | WARNING - DO NOT EXCEED |

30 PSIG GAS DELIVERY | 30 PSIG GAS DELIVERY |

PRESSURE | PRESSURE |

EXHAUST | WARNING - THIS GAS MAY CONTAIN HARMFUL LEVELS OF OZONE |

Figure 2-2 Pneumatic Connections

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 12