All installations and services must be performed by qualified service personnel.

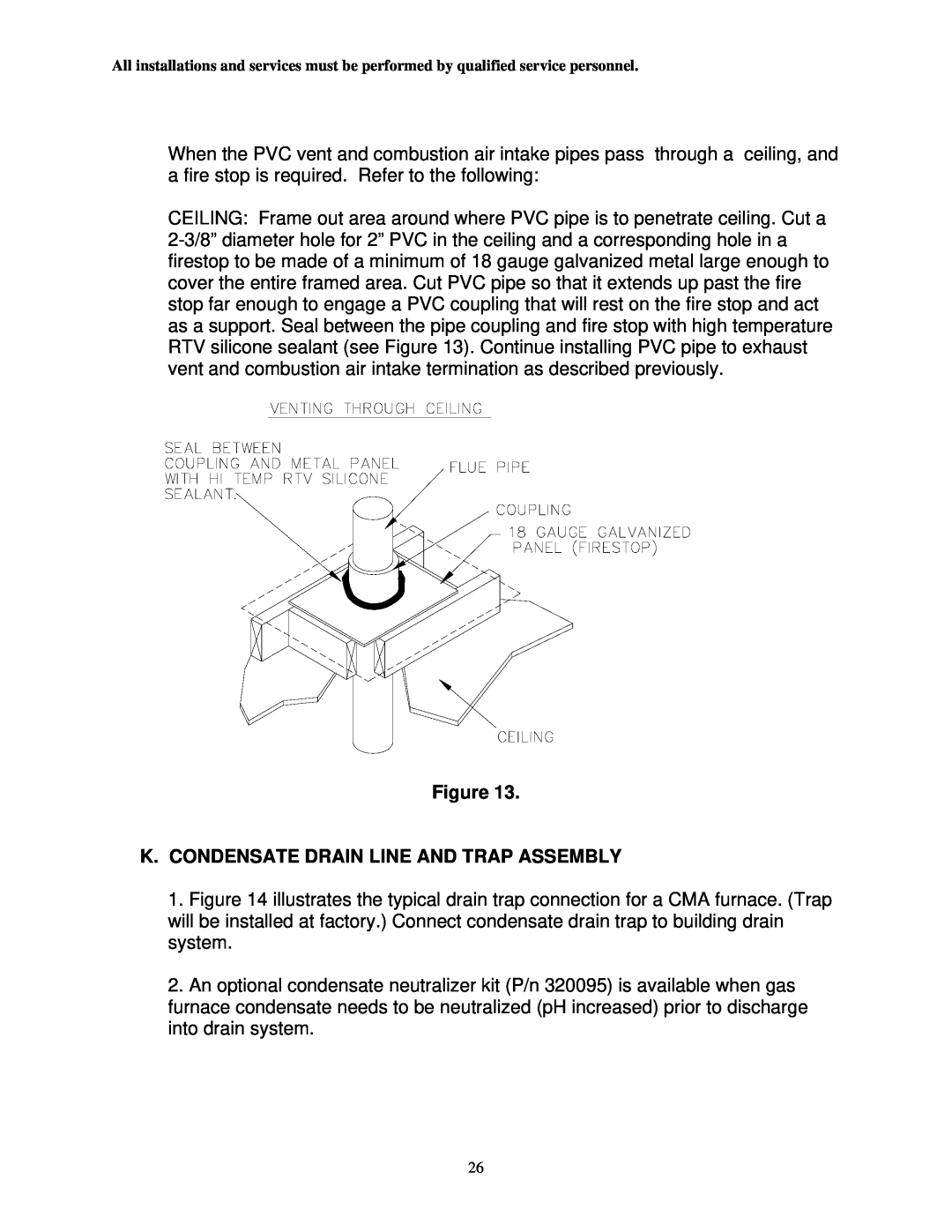

When the PVC vent and combustion air intake pipes pass through a ceiling, and a fire stop is required. Refer to the following:

CEILING: Frame out area around where PVC pipe is to penetrate ceiling. Cut a

Figure 13.

K.CONDENSATE DRAIN LINE AND TRAP ASSEMBLY

1.Figure 14 illustrates the typical drain trap connection for a CMA furnace. (Trap will be installed at factory.) Connect condensate drain trap to building drain system.

2.An optional condensate neutralizer kit (P/n 320095) is available when gas furnace condensate needs to be neutralized (pH increased) prior to discharge into drain system.

26