All installations and services must be performed by qualified service personnel.

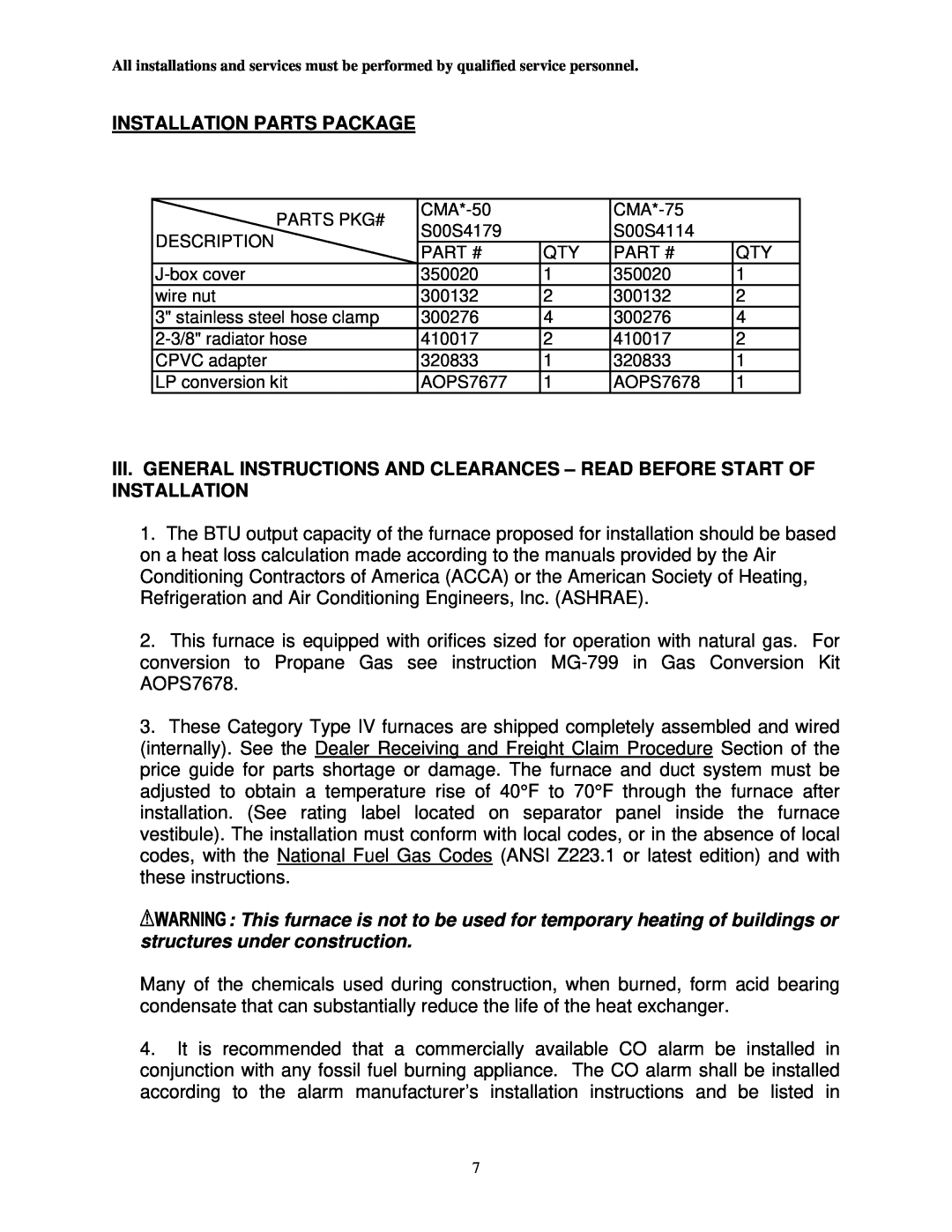

INSTALLATION PARTS PACKAGE

PARTS PKG# |

|

| |||

S00S4179 |

| S00S4114 |

| ||

DESCRIPTION |

|

| |||

PART # | QTY | PART # | QTY | ||

| |||||

350020 | 1 | 350020 | 1 | ||

wire nut | 300132 | 2 | 300132 | 2 | |

3" stainless steel hose clamp | 300276 | 4 | 300276 | 4 | |

410017 | 2 | 410017 | 2 | ||

CPVC adapter | 320833 | 1 | 320833 | 1 | |

LP conversion kit | AOPS7677 | 1 | AOPS7678 | 1 |

III.GENERAL INSTRUCTIONS AND CLEARANCES – READ BEFORE START OF INSTALLATION

1.The BTU output capacity of the furnace proposed for installation should be based on a heat loss calculation made according to the manuals provided by the Air Conditioning Contractors of America (ACCA) or the American Society of Heating, Refrigeration and Air Conditioning Engineers, Inc. (ASHRAE).

2.This furnace is equipped with orifices sized for operation with natural gas. For conversion to Propane Gas see instruction

3.These Category Type IV furnaces are shipped completely assembled and wired (internally). See the Dealer Receiving and Freight Claim Procedure Section of the price guide for parts shortage or damage. The furnace and duct system must be adjusted to obtain a temperature rise of 40°F to 70°F through the furnace after installation. (See rating label located on separator panel inside the furnace vestibule). The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Codes (ANSI Z223.1 or latest edition) and with these instructions.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() : This furnace is not to be used for temporary heating of buildings or structures under construction.

: This furnace is not to be used for temporary heating of buildings or structures under construction.

Many of the chemicals used during construction, when burned, form acid bearing condensate that can substantially reduce the life of the heat exchanger.

4.It is recommended that a commercially available CO alarm be installed in conjunction with any fossil fuel burning appliance. The CO alarm shall be installed according to the alarm manufacturer’s installation instructions and be listed in

7