3.2Original Size Detection

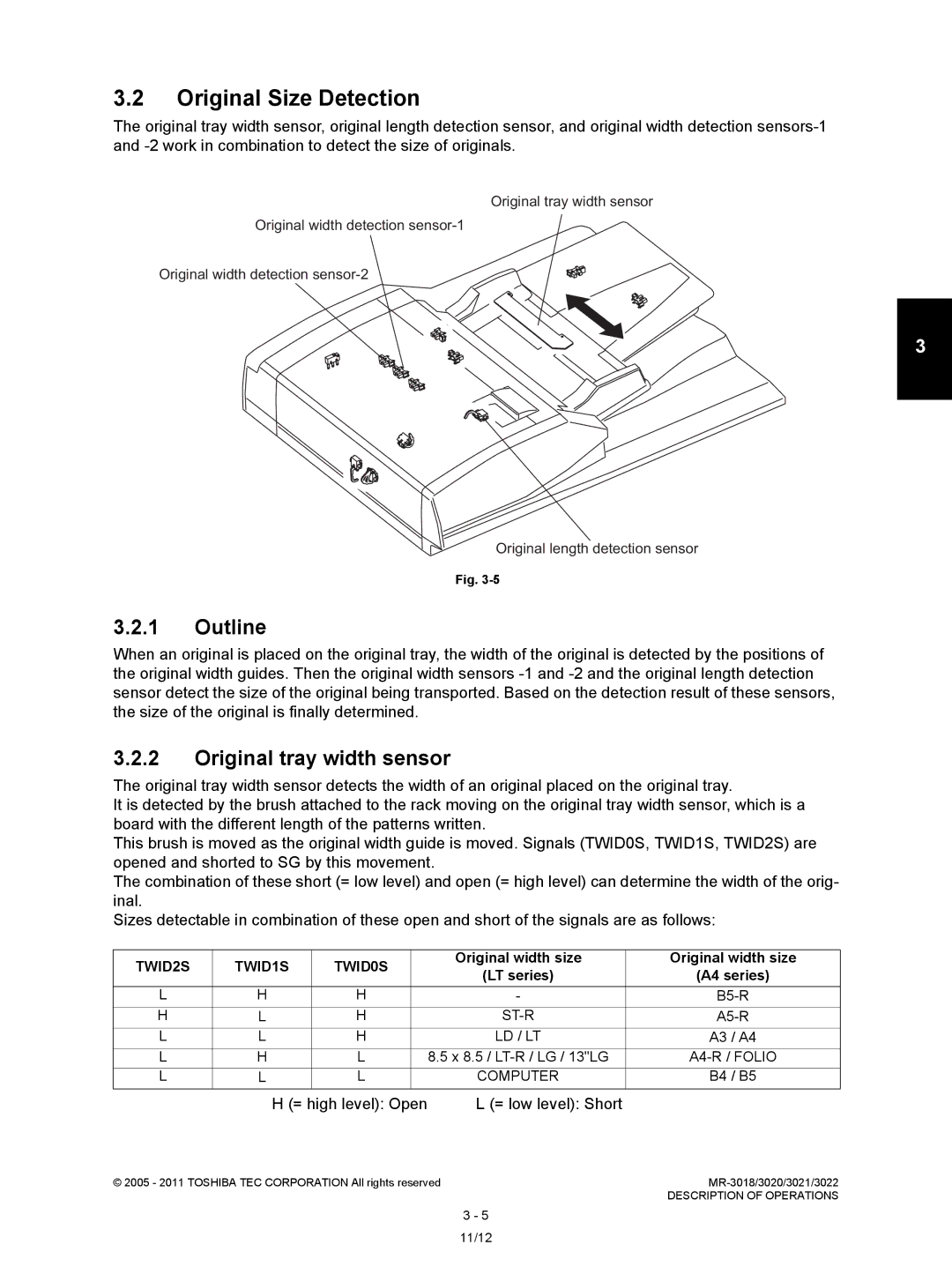

The original tray width sensor, original length detection sensor, and original width detection

Original tray width sensor

Original width detection

Original width detection

3 |

Original length detection sensor

Fig.

3.2.1Outline

When an original is placed on the original tray, the width of the original is detected by the positions of the original width guides. Then the original width sensors

3.2.2Original tray width sensor

The original tray width sensor detects the width of an original placed on the original tray.

It is detected by the brush attached to the rack moving on the original tray width sensor, which is a board with the different length of the patterns written.

This brush is moved as the original width guide is moved. Signals (TWID0S, TWID1S, TWID2S) are opened and shorted to SG by this movement.

The combination of these short (= low level) and open (= high level) can determine the width of the orig- inal.

Sizes detectable in combination of these open and short of the signals are as follows:

TWID2S | TWID1S | TWID0S |

| Original width size | Original width size |

| (LT series) | (A4 series) | |||

|

|

|

| ||

L | H | H |

| - | |

H | L | H |

| ||

L | L | H |

| LD / LT | A3 / A4 |

L | H | L |

| 8.5 x 8.5 / | |

L | L | L |

| COMPUTER | B4 / B5 |

| H (= high level): Open | L (= low level): Short |

| ||

© 2005 - 2011 TOSHIBA TEC CORPORATION All rights reserved | |

| DESCRIPTION OF OPERATIONS |

3 - 5