Controls VAV and CV

| Design | Space CO2 Level |

|

| |

| Min OA |

|

| Damper |

|

Minimum | Setpoint |

|

| Min OA | |

|

| |

|

| Damper |

|

| Position |

Damper | DCV Min | Target |

| ||

| OA |

|

| Damper |

|

OA | Setpoint |

|

|

| |

| CO2 Min | CO2 Design |

| Setpoint | Setpoint |

CO2 Level

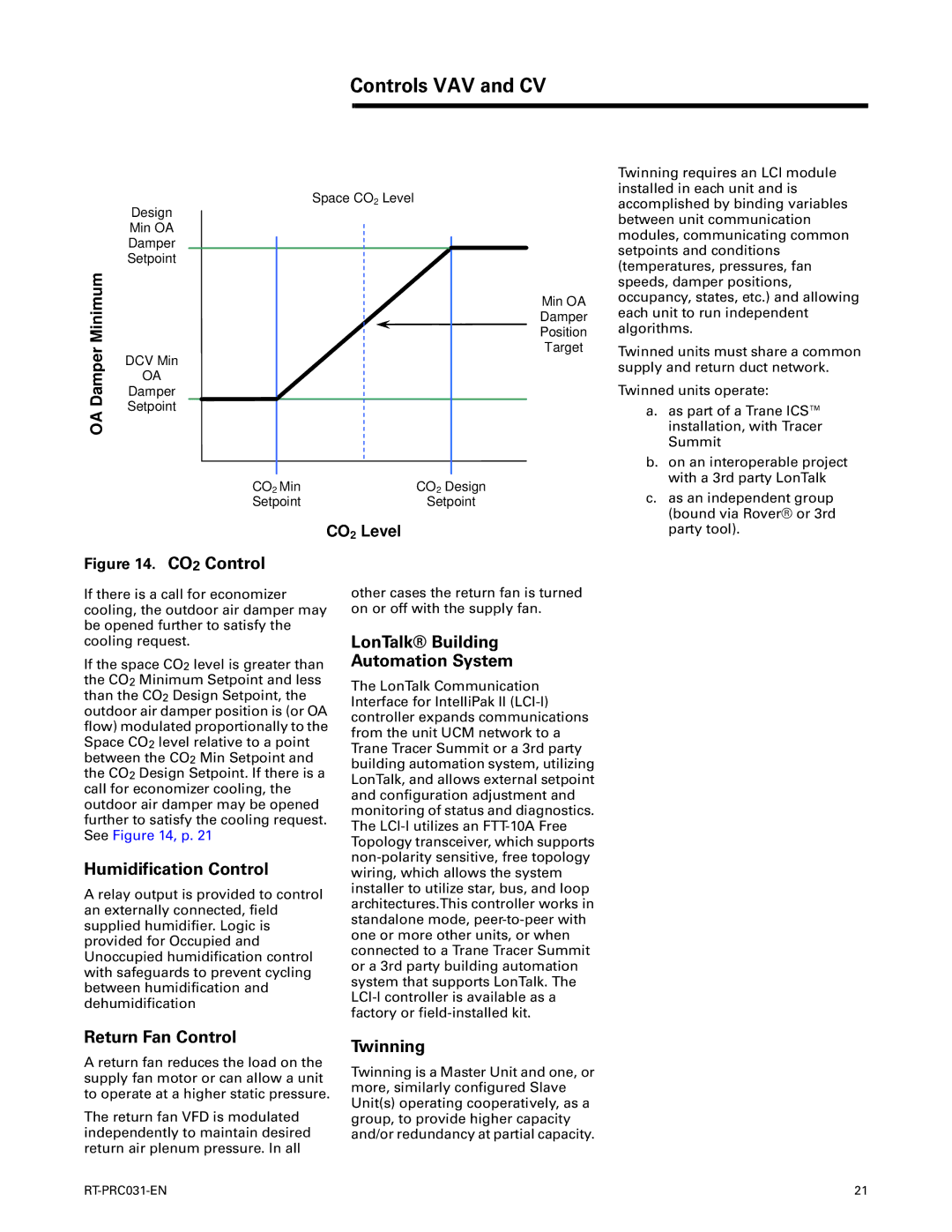

Figure 14. CO2 Control

Twinning requires an LCI module installed in each unit and is accomplished by binding variables between unit communication modules, communicating common setpoints and conditions (temperatures, pressures, fan speeds, damper positions, occupancy, states, etc.) and allowing each unit to run independent algorithms.

Twinned units must share a common supply and return duct network.

Twinned units operate:

a.as part of a Trane ICS™ installation, with Tracer Summit

b.on an interoperable project with a 3rd party LonTalk

c.as an independent group (bound via Rover® or 3rd party tool).

If there is a call for economizer cooling, the outdoor air damper may be opened further to satisfy the cooling request.

If the space CO2 level is greater than the CO2 Minimum Setpoint and less than the CO2 Design Setpoint, the outdoor air damper position is (or OA flow) modulated proportionally to the Space CO2 level relative to a point between the CO2 Min Setpoint and the CO2 Design Setpoint. If there is a call for economizer cooling, the outdoor air damper may be opened further to satisfy the cooling request. See Figure 14, p. 21

Humidification Control

A relay output is provided to control an externally connected, field supplied humidifier. Logic is provided for Occupied and Unoccupied humidification control with safeguards to prevent cycling between humidification and dehumidification

other cases the return fan is turned on or off with the supply fan.

LonTalk® Building

Automation System

The LonTalk Communication Interface for IntelliPak II

Return Fan Control

A return fan reduces the load on the supply fan motor or can allow a unit to operate at a higher static pressure.

The return fan VFD is modulated independently to maintain desired return air plenum pressure. In all

Twinning

Twinning is a Master Unit and one, or more, similarly configured Slave Unit(s) operating cooperatively, as a group, to provide higher capacity and/or redundancy at partial capacity.

21 |