Models

Later Design Sequence

With 3-DTMScroll Compressors

Overview of Manual

Literature Change History

Table of Contents

Model Number Description

General Information

Digit 3 Unit Airflow

Unit Description

Fiberglass Wool

Hazard Identification

General Information Commonly Used Acronyms

Supply AIR

General Information

CFM

Ventilation Control Module VCM Design special option only

Lead-Lag

Constant Volume CV Units

Unit Component Layout and Shipwith Locations

Variable Air Volume VAV Units

General Information Space Temperature Averaging

Control Module Locations for SHF 40, 60, 70 & 75 Ton Units

Table of Contents

Storage

Unit Dimensions & Weight Information

No Step Surface

Unit Inspection As soon as the unit arrives at the job site

Page

Sahf Cooling-Only Units 20 thru 75 Ton

Electrical Entrance Data Unit Dimensions

Installation

Unit Dimensional Data Dimensions Size

Unit Base Dimensional Data Dimensions

SEHF, SFHF, SLHF, SSHF, Sxhf Units 20 thru 75 Ton

Unit Size Furnace Dimensions Note Size/MBH Length Height

Unit Base Dimensional Data Dimensions Size

Unit Dimensions Size

Electrical Entrance Data Unit Dimensions Size

SHG Cooling & Heating Units 90 through 130 Ton

Sshf

Sahf

Sehf

Slhf

Roof Curb and Ductwork

SE,SL

Sahf Sshf Sfhf Sxhf Sehg Sfhg Sxhg HF/G

Pitch Pocket Location

Installation Unit Rigging & Placement

If a Trane Curb Accessory Kit is not used

Heavy Objects

Typical Unit Rigging Unit Base & Roof Curb Section

Requirements for Electric Heat Units

Main Electrical Power Requirements

Installation Field Installed Control Wiring

General Unit Requirements

Installation

Condensate Drain Connections

Page

Removing Supply and Exhaust Fan Shipping Channels Motors 5Hp

Page

Units with StatitracTM

Installation Sensor & Tubing Installation

Connecting the Gas Supply Line to the Furnace Gas Train

Hazardous Gases and Flammable Vapors

Gas Heat Units SFH

350 MBH 850 MBH

Hot Water Heat Units SLH

Flue Assembly Installation

Flue Assembly

1000 MBH Modulating 500 MBH 1000 MBH

SSHG-90

Steam Heat Units SSH

Through 130 Ton units

Page

Hazardous Voltage

Live Electrical Components

Use Copper Conductors Only

Typical Field Power Wiring 20 thru 75 Ton

Page

FLA

Supply Fan Motor FLA ea Horsepower

Condenser Fans Total FLA

Exhaust Fan Motor

Combustion

Blower Motor Sfhf Only

Unit Tonnage No. of Compressors Tonnage Type Designation

On the Next

Single Source Power 380V, 415V, 460V,

Load Definitions Load

= Current of the Largest Motor Compressor or FAN Motor

MCA = 1.25 x Load MOP = 1.25 x Load

Power Wire Sizing and Protection Device Equations

Disconnect Switch Sizing DSS

Dual Source Power units 200V

Controls using 24 VAC

Installation Controls using DC Analog Input/Outputs

Constant Volume System Controls

Constant Volume or Variable Air Volume System Controls

Variable Air Volume System Controls

Depressurize

Pressurize

Fire

Purge

16A

Refer to Wiring Notes on

16B

Page

17A

17B

Input Voltage

VAV Setpoint

Table of Contents

Sequence of Operation

Cooling Sequence of Operation

Propane Gas

Gas Heating Sequence of Operation

Fenwal Ignition System

Unit Start-Up

Modulating Gas Sequence of Operation

Flame Failure

Full and Limited Modulating Gas Furnace

Electric Heat Sequence of Operation

Unit Start-Up Wet Heat Sequence of Operation

Freeze Protection

Unit Power

Compressor Damage

Electrical Phasing

Voltage Supply and Voltage Imbalance

Voltage Supply

Voltage Imbalance

IGV

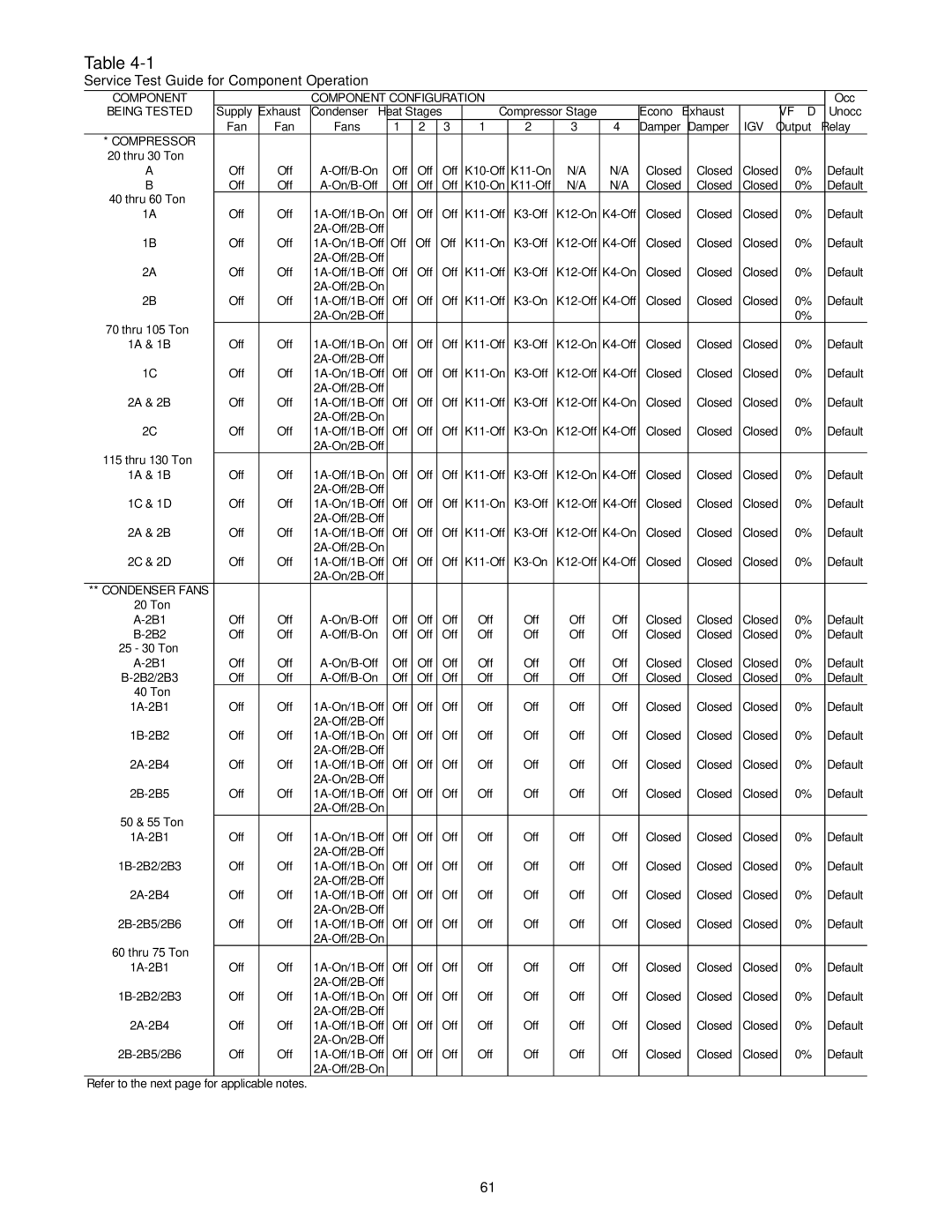

Service Test Guide for Component Operation

Supply FAN

If all of the fans are rotating backwards

System Airflow Measurements Constant Volume Systems

Rotating Components

Verifying Proper Fan Rotation

Condenser Fan Location with Human Interface Designator

Variable Air Volume Systems

Optional with all units equipped with an economizer

Exhaust Airflow Measurement

TraqTM Sensor Airflow Measurement

Optional with all Units

Ton Supply Fan Performance without Inlet Guide Vanes

20 & 25 Ton Supply Fan Performance without Inlet Guide Vanes

Wocfm 1200 RPM 40 HP 40%

300 RP

Standard Evaporator Coil

20000 30000 40000 50000 60000

Drop

Ton Supply Fan Performance with Inlet Guide Vanes

20 & 25 Ton Supply Fan Performance with Inlet Guide Vanes

15 HP 900 RPM 80% 10 HP

RPM

AIR

Through 75 Ton Component Static Pressure Drops Inches W.C

STD

AIR

CFM RPM BHP

HF-C30 000

HF-C20 000

HF-C25 000

10,000

AIR RPM BHP

RPM BHP BHP RPM BHP RPM BHP

Fresh Air & Return Air Damper Operation

Economizer Damper Adjustment

To Adjust the Fresh Air Damper Travel

Exhaust Air Dampers

Ton Units

Damper Travel Adjustment Position

Connecting Rod Crank Arm Hole

Configuration

70 & 105 Ton

Fresh Air & Return Air Linkage Adjustment

Compressor Start-Up

All Systems

At Low Ambient Start-Up

Compressor Operational Sounds

Refrigerant Charging

At Shutdown

Compressor Locations

Cooling Cycle Pressure Curve

340 320

Full Load

380 360 340 OD Ambient

Full Load

380 360 340 OD Ambient 320

240 220

380 360 OD Ambient

Thermostatic Expansion Valves

Charging by Subcooling

Low Ambient Dampers

Gas Furnace Start-Up

Electric, Steam and Hot Water Start-Up

Two Stage Gas Furnace

High-Fire Adjustment

Combustion Air Adjustment O2

Low-Fire Adjustment 500 MBH, 850 & 1,000 MBH only

MBH

Firing Manifold

CO2 Pressure

Full Modulating Gas Furnace

Heat Exchanger

Unit control

Limited Modulating Gas Furnace Unit Start-Up

Modulating Gas Regulator

Modulating Gas Regulator Legend

Typical Gas Furnace

Unit Start-Up Final Unit Checkout

Service & Maintenance

Unit Internal Fuse Replacement Data & VFD Factory Settings

Service & Maintenance

Model Type

Unit Model Box-type Note Qty

Qty Size of each

Wet Heat Coil Fin Data Total Coil Fins

Service & Maintenance

Fan Belt Adjustment

Scroll Compressor Replacement

Suction Line Filter/Drier Installation

Gripbelts Gripnotch Cross Small P.D Section Range Min Max

Hazardous Voltage! w/Capacitors

VFD Programming Parameters

Supply and Exhaust Fan VFD Programming Parameters

Service & Maintenance Monthly Maintenance

Filters

Cooling Season

Heating Season

Coil Cleaning

Coil Cleaners

Contains Refrigerant

Steam or Hot Water Coils

Final Process

Index

See Figure Gate type valve 36-37 See -12 Figure

See VOM Contacts -16 Figure

Equipment Damage From Ultraviolet UV Lights

Warranty and Liability Clause

115

116