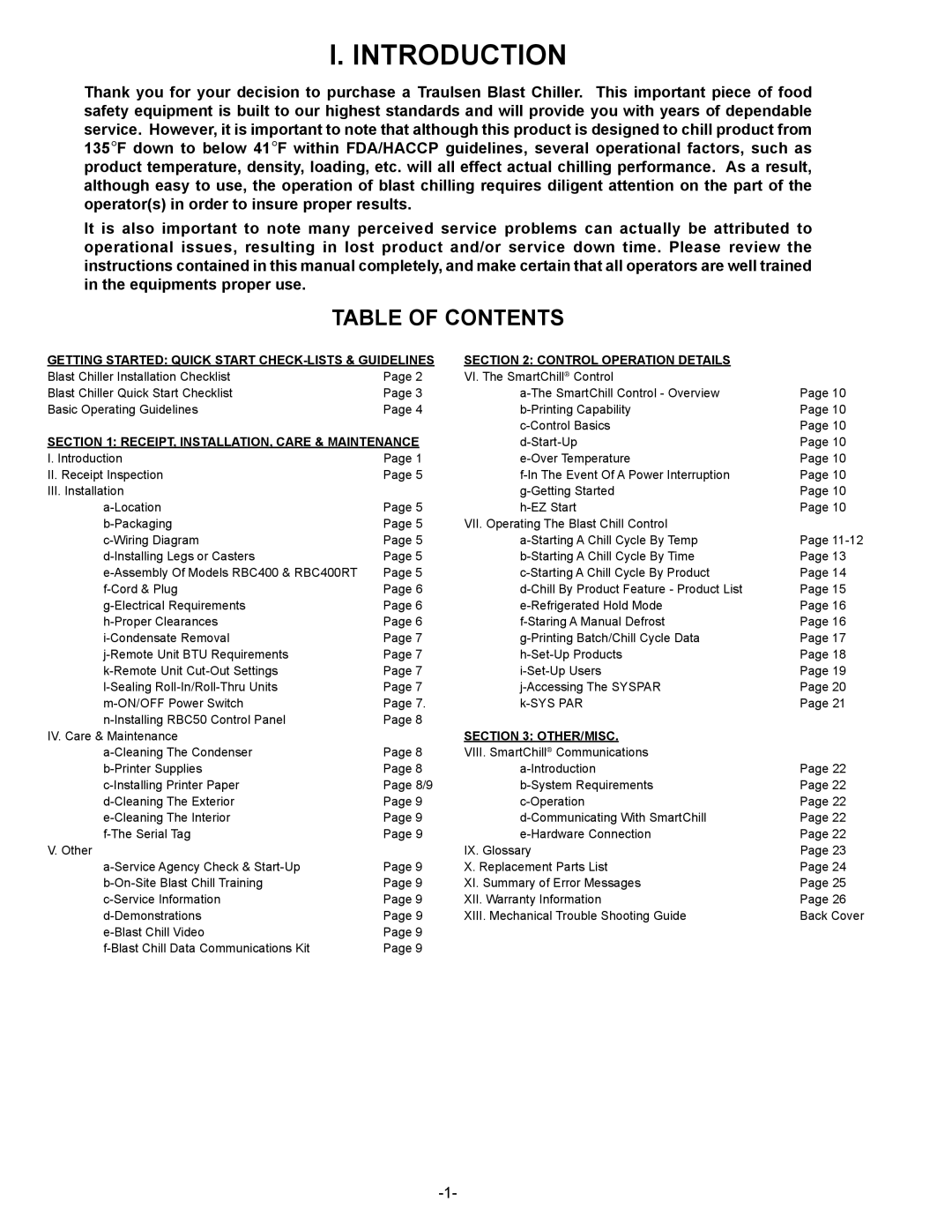

I. INTRODUCTION

Thank you for your decision to purchase a Traulsen Blast Chiller. This important piece of food safety equipment is built to our highest standards and will provide you with years of dependable service. However, it is important to note that although this product is designed to chill product from 135°F down to below 41°F within FDA/HACCP guidelines, several operational factors, such as product temperature, density, loading, etc. will all effect actual chilling performance. As a result, although easy to use, the operation of blast chilling requires diligent attention on the part of the operator(s) in order to insure proper results.

It is also important to note many perceived service problems can actually be attributed to operational issues, resulting in lost product and/or service down time. Please review the instructions contained in this manual completely, and make certain that all operators are well trained in the equipments proper use.

TABLE OF CONTENTS

GETTING STARTED: QUICK START | SECTION 2: CONTROL OPERATION DETAILS |

| |

Blast Chiller Installation Checklist | Page 2 | VI. The SmartChill® Control |

|

Blast Chiller Quick Start Checklist | Page 3 | Page 10 | |

Basic Operating Guidelines | Page 4 | Page 10 | |

|

| Page 10 | |

SECTION 1: RECEIPT, INSTALLATION, CARE & MAINTENANCE | Page 10 | ||

I. Introduction | Page 1 | Page 10 | |

II. Receipt Inspection | Page 5 | Page 10 | |

III. Installation |

| Page 10 | |

Page 5 | Page 10 | ||

Page 5 | VII. Operating The Blast Chill Control |

| |

Page 5 | Page | ||

Page 5 | Page 13 | ||

Page 5 | Page 14 | ||

Page 6 | Page 15 | ||

Page 6 | Page 16 | ||

Page 6 | Page 16 | ||

Page 7 | Page 17 | ||

Page 7 | Page 18 | ||

Page 7 | Page 19 | ||

Page 7 | Page 20 | ||

Page 7. | Page 21 | ||

Page 8 |

|

| |

IV. Care & Maintenance |

| SECTION 3: OTHER/MISC. |

|

Page 8 | VIII. SmartChill® Communications |

| |

Page 8 | Page 22 | ||

Page 8/9 | Page 22 | ||

Page 9 | Page 22 | ||

Page 9 | Page 22 | ||

Page 9 | Page 22 | ||

V. Other |

| IX. Glossary | Page 23 |

Page 9 | X. Replacement Parts List | Page 24 | |

Page 9 | XI. Summary of Error Messages | Page 25 | |

Page 9 | XII. Warranty Information | Page 26 | |

Page 9 | XIII. Mechanical Trouble Shooting Guide | Back Cover | |

Page 9 |

|

| |

Page 9 |

|

| |