III. INSTALLATION (continued)

III.i - CONDENSATE REMOVAL:

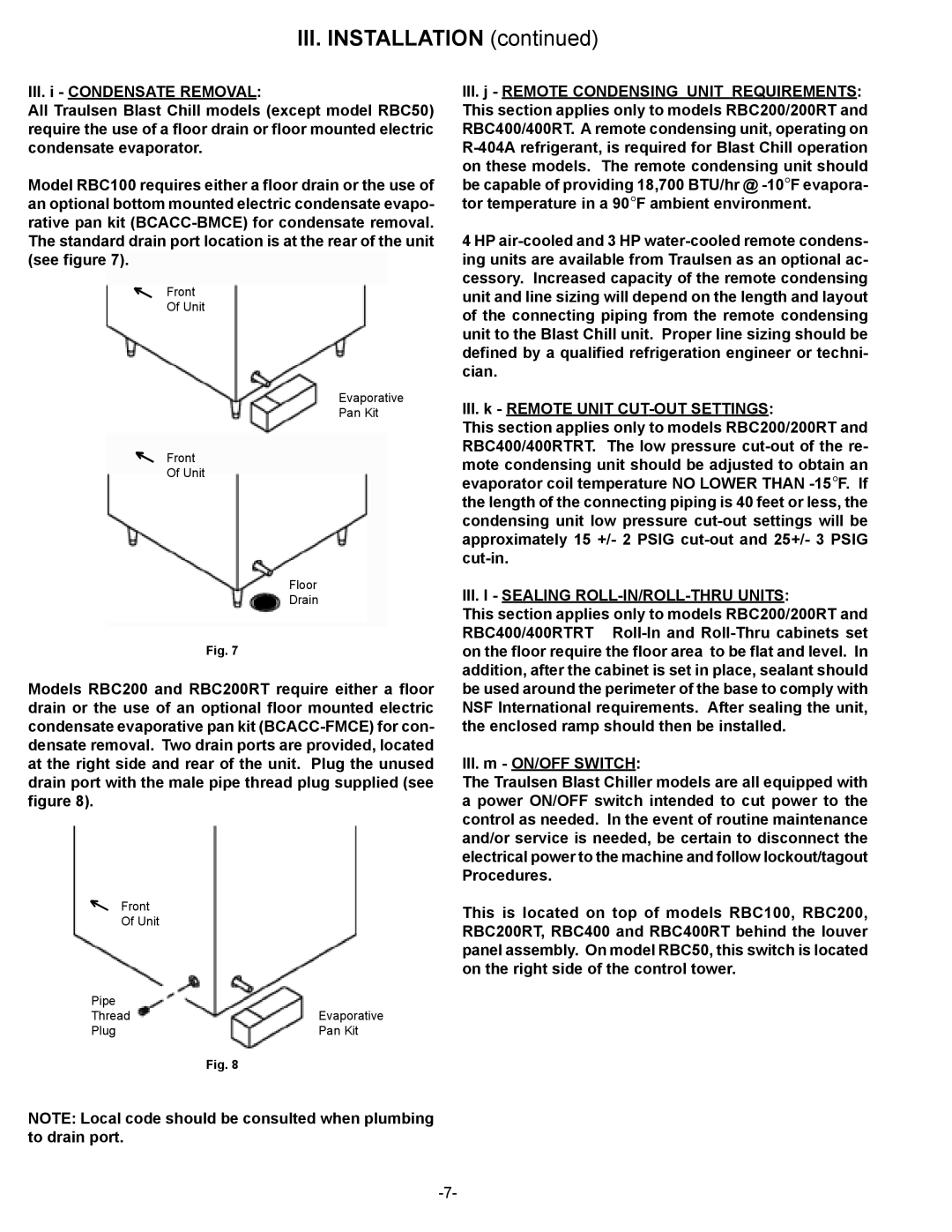

All Traulsen Blast Chill models (except model RBC50) require the use of a floor drain or floor mounted electric condensate evaporator.

Model RBC100 requires either a floor drain or the use of an optional bottom mounted electric condensate evapo- rative pan kit

↑ | Front |

| |

| Of Unit |

Evaporative

Pan Kit

↑ | Front |

| |

| Of Unit |

Floor

Drain

Fig. 7

Models RBC200 and RBC200RT require either a floor drain or the use of an optional floor mounted electric condensate evaporative pan kit

↑ | Front |

| |

| Of Unit |

Pipe |

|

Thread | Evaporative |

Plug | Pan Kit |

| Fig. 8 |

III.j - REMOTE CONDENSING UNIT REQUIREMENTS: This section applies only to models RBC200/200RT and RBC400/400RT. A remote condensing unit, operating on

4 HP

III.k - REMOTE UNIT

This section applies only to models RBC200/200RT and RBC400/400RTRT. The low pressure

III.l - SEALING

This section applies only to models RBC200/200RT and RBC400/400RTRT

III.m - ON/OFF SWITCH:

The Traulsen Blast Chiller models are all equipped with a power ON/OFF switch intended to cut power to the control as needed. In the event of routine maintenance and/or service is needed, be certain to disconnect the electrical power to the machine and follow lockout/tagout Procedures.

This is located on top of models RBC100, RBC200, RBC200RT, RBC400 and RBC400RT behind the louver panel assembly. On model RBC50, this switch is located on the right side of the control tower.

NOTE: Local code should be consulted when plumbing to drain port.