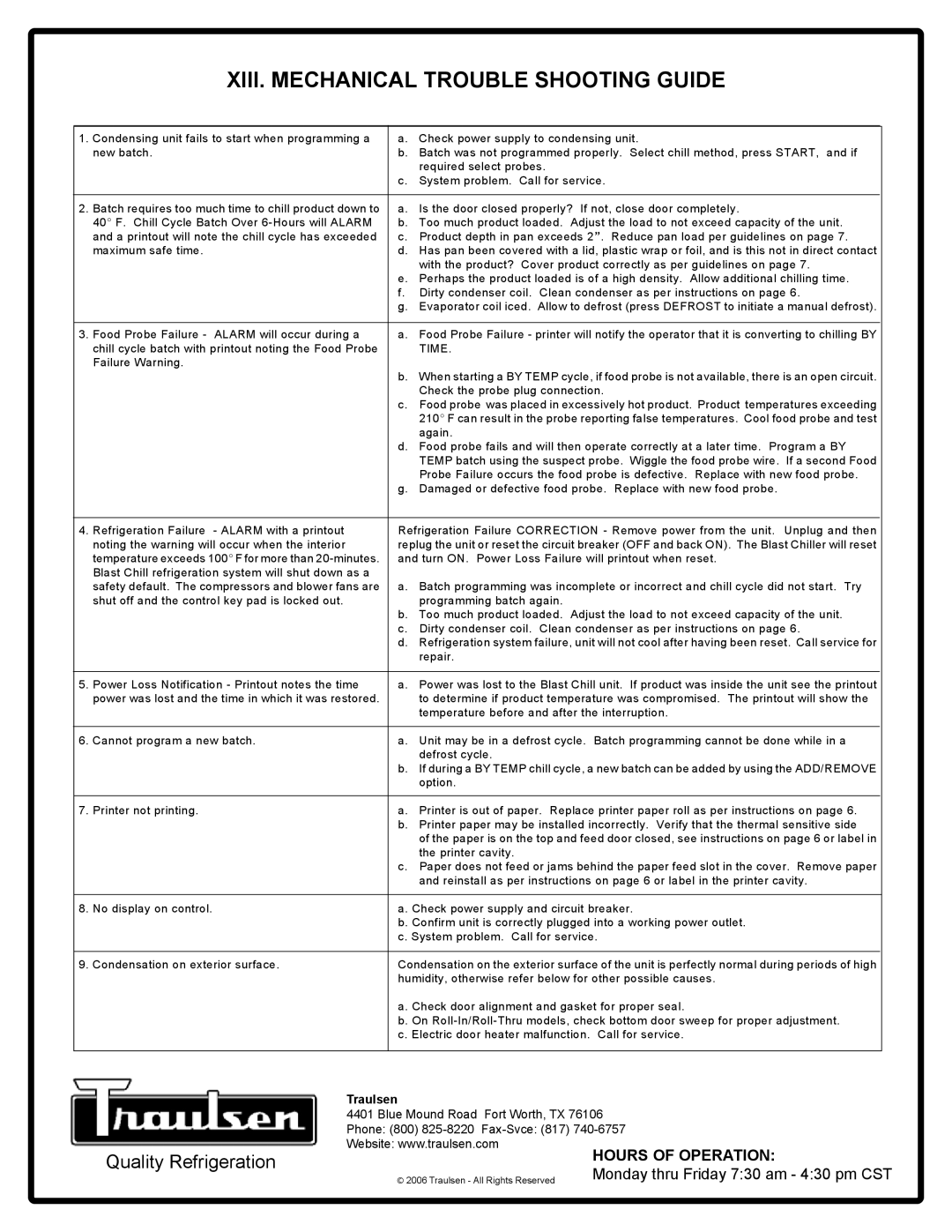

XIII. MECHANICAL TROUBLE SHOOTING GUIDE

1. Condensing unit fails to start when programming a | a. | Check power supply to condensing unit. |

|

new batch. | b. | Batch was not programmed properly. Select chill method, press START, and if |

|

|

| required select probes. |

|

| c. | System problem. Call for service. |

|

|

|

|

|

2. Batch requires too much time to chill product down to | a. | Is the door closed properly? If not, close door completely. |

|

40° F. Chill Cycle Batch Over | b. | Too much product loaded. Adjust the load to not exceed capacity of the unit. |

|

and a printout will note the chill cycle has exceeded | c. | Product depth in pan exceeds 2”. Reduce pan load per guidelines on page 7. |

|

maximum safe time. | d. | Has pan been covered with a lid, plastic wrap or foil, and is this not in direct contact |

|

|

| with the product? Cover product correctly as per guidelines on page 7. |

|

| e. | Perhaps the product loaded is of a high density. Allow additional chilling time. |

|

| f. | Dirty condenser coil. Clean condenser as per instructions on page 6. |

|

| g. | Evaporator coil iced. Allow to defrost (press DEFROST to initiate a manual defrost). |

|

|

|

|

|

3. Food Probe Failure - ALARM will occur during a | a. | Food Probe Failure - printer will notify the operator that it is converting to chilling BY |

|

chill cycle batch with printout noting the Food Probe |

| TIME. |

|

Failure Warning. |

|

|

|

| b. | When starting a BY TEMP cycle, if food probe is not available, there is an open circuit. |

|

|

| Check the probe plug connection. |

|

| c. | Food probe was placed in excessively hot product. Product temperatures exceeding |

|

|

| 210° F can result in the probe reporting false temperatures. Cool food probe and test |

|

|

| again. |

|

| d. | Food probe fails and will then operate correctly at a later time. Program a BY |

|

|

| TEMP batch using the suspect probe. Wiggle the food probe wire. If a second Food |

|

|

| Probe Failure occurs the food probe is defective. Replace with new food probe. |

|

| g. | Damaged or defective food probe. Replace with new food probe. |

|

|

|

| |

4. Refrigeration Failure - ALARM with a printout | Refrigeration Failure CORRECTION - Remove power from the unit. Unplug and then |

| |

noting the warning will occur when the interior | replug the unit or reset the circuit breaker (OFF and back ON). The Blast Chiller will reset |

| |

temperature exceeds 100° F for more than | and turn ON. Power Loss Failure will printout when reset. |

| |

Blast Chill refrigeration system will shut down as a |

|

|

|

safety default. The compressors and blower fans are | a. | Batch programming was incomplete or incorrect and chill cycle did not start. Try |

|

shut off and the control key pad is locked out. |

| programming batch again. |

|

| b. | Too much product loaded. Adjust the load to not exceed capacity of the unit. |

|

| c. | Dirty condenser coil. Clean condenser as per instructions on page 6. |

|

| d. | Refrigeration system failure, unit will not cool after having been reset. Call service for |

|

|

| repair. |

|

|

|

|

|

5. Power Loss Notification - Printout notes the time | a. | Power was lost to the Blast Chill unit. If product was inside the unit see the printout |

|

power was lost and the time in which it was restored. |

| to determine if product temperature was compromised. The printout will show the |

|

|

| temperature before and after the interruption. |

|

|

|

|

|

6. Cannot program a new batch. | a. | Unit may be in a defrost cycle. Batch programming cannot be done while in a |

|

|

| defrost cycle. |

|

| b. | If during a BY TEMP chill cycle, a new batch can be added by using the ADD/REMOVE |

|

|

| option. |

|

|

|

|

|

7. Printer not printing. | a. | Printer is out of paper. Replace printer paper roll as per instructions on page 6. |

|

| b. | Printer paper may be installed incorrectly. Verify that the thermal sensitive side |

|

|

| of the paper is on the top and feed door closed, see instructions on page 6 or label in |

|

|

| the printer cavity. |

|

| c. | Paper does not feed or jams behind the paper feed slot in the cover. Remove paper |

|

|

| and reinstall as per instructions on page 6 or label in the printer cavity. |

|

|

|

| |

8. No display on control. | a. Check power supply and circuit breaker. |

| |

| b. Confirm unit is correctly plugged into a working power outlet. |

| |

| c. System problem. Call for service. |

| |

|

|

| |

9. Condensation on exterior surface. | Condensation on the exterior surface of the unit is perfectly normal during periods of high |

| |

| humidity, otherwise refer below for other possible causes. |

| |

a. Check door alignment and gasket for proper seal.

b.On

c.Electric door heater malfunction. Call for service.

Quality Refrigeration

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800)

Website: www.traulsen.com

HOURS OF OPERATION:

© 2006 Traulsen - All Rights Reserved | Monday thru Friday 7:30 am - 4:30 pm CST |

|