Symptom | Probable Cause |

| Corrective Action |

|

|

|

|

| |

ECB | Control Panel | • | Power on unit. Check for 5VDC between pins 1 and 2. (Page 18) | |

MALFUNCTION |

| • | No 5VDC? Replace control panel. | |

500R, 500U |

| • | Check for 6VDC or more between pins 5 and 6 of 6PA while issuing | |

|

|

| a resistance command. |

|

|

| • No 6VDC or more? Replace control panel. | ||

|

|

|

| |

| Defective Cables | • Perform continuity check on upper section and lower section cables. | ||

|

| |||

|

| • | Replace broken cables. |

|

|

|

|

| |

| Defective ECB | • If cables test OK and voltage is correct on 5 &6 pins – replace ECB | ||

| Control Board | |||

|

| board |

| |

|

|

|

| |

|

| • If ECB does not fix- connect 6PA and 6PB. | ||

|

|

|

| |

| Optical Sensor | • Check DC volts between pins 2 and 3. Rotate blades of the motor | ||

|

| |||

|

|

| shaft, voltage should shift from 0 VDC and 5VDC. If voltage does | |

| DC Motor |

| not shift- replace EC B Board | |

| • Check for 6 VDC or more between pins 5&6 on 6 pin PBA @ ECB | |||

|

| |||

|

|

| board connection. If >6 VDC exists but motor doesn’t rotate, replace | |

|

|

| motor. |

|

|

|

|

| |

| ECB Limit Switch | • Check continuity between pins 2 and 4 of 6PB. Press lower limit | ||

|

| |||

|

|

| switch. |

|

|

| • If no continuity shift- replace ECB limit switch assembly. | ||

|

|

| ||

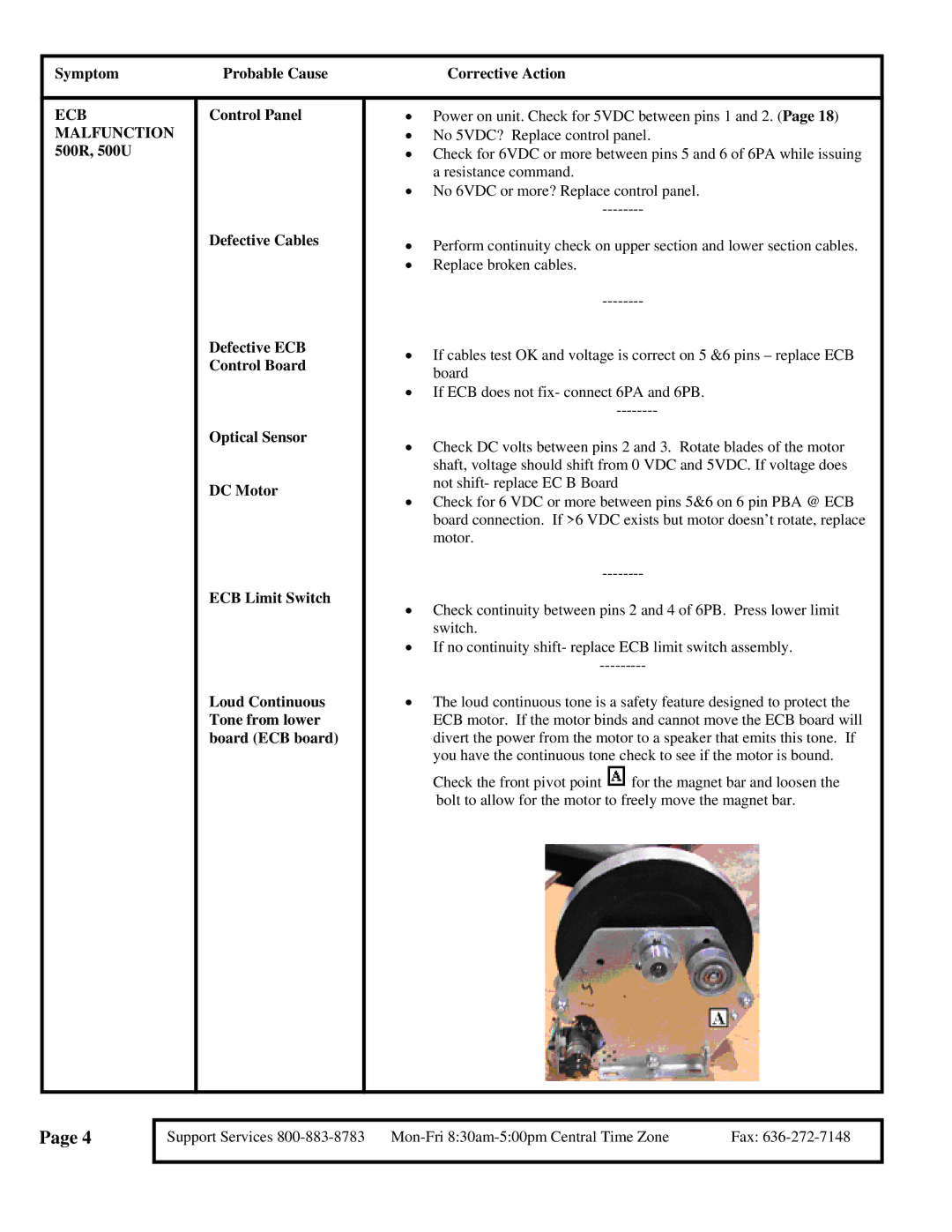

| Loud Continuous | • | The loud continuous tone is a safety feature designed to protect the | |

| Tone from lower |

| ECB motor. If the motor binds and cannot move the ECB board will | |

| board (ECB board) |

| divert the power from the motor to a speaker that emits this tone. If | |

|

|

| you have the continuous tone check to see if the motor is bound. | |

|

|

| Check the front pivot point | for the magnet bar and loosen the |

|

|

| bolt to allow for the motor to freely move the magnet bar. | |

Note: If motor has been bound and then freed the motor may have been weakened. If components now move freely but the motor is laboring – replace the motor.

Page 4

Support Services | Fax: | |

|

|

|