Maintenance Instructions | ADJUSTMENTS |

Decrease

Chain Tension

Support

Box Bolts

Increase

Chain Tension

Reduction Chain Tension Adjustment

Debris Blower Front Gauge Wheel

Adjust the gauge wheel height according to surface condition.

IMPORTANT: The air blast nozzle must clear the ground at all times.

1.Remove the linchpin from the wheel pivot shaft.

2.Adjust wheel height by placing sleeve spacers either on the upper or lower side of the wheel pivot bushing. Placing the spacers on the low- er side increases gauge wheel height. Placing the spacers on the upper side lowers gauge wheel height.

3.Reinstall the linchpin when proper gauge wheel height has been reached.

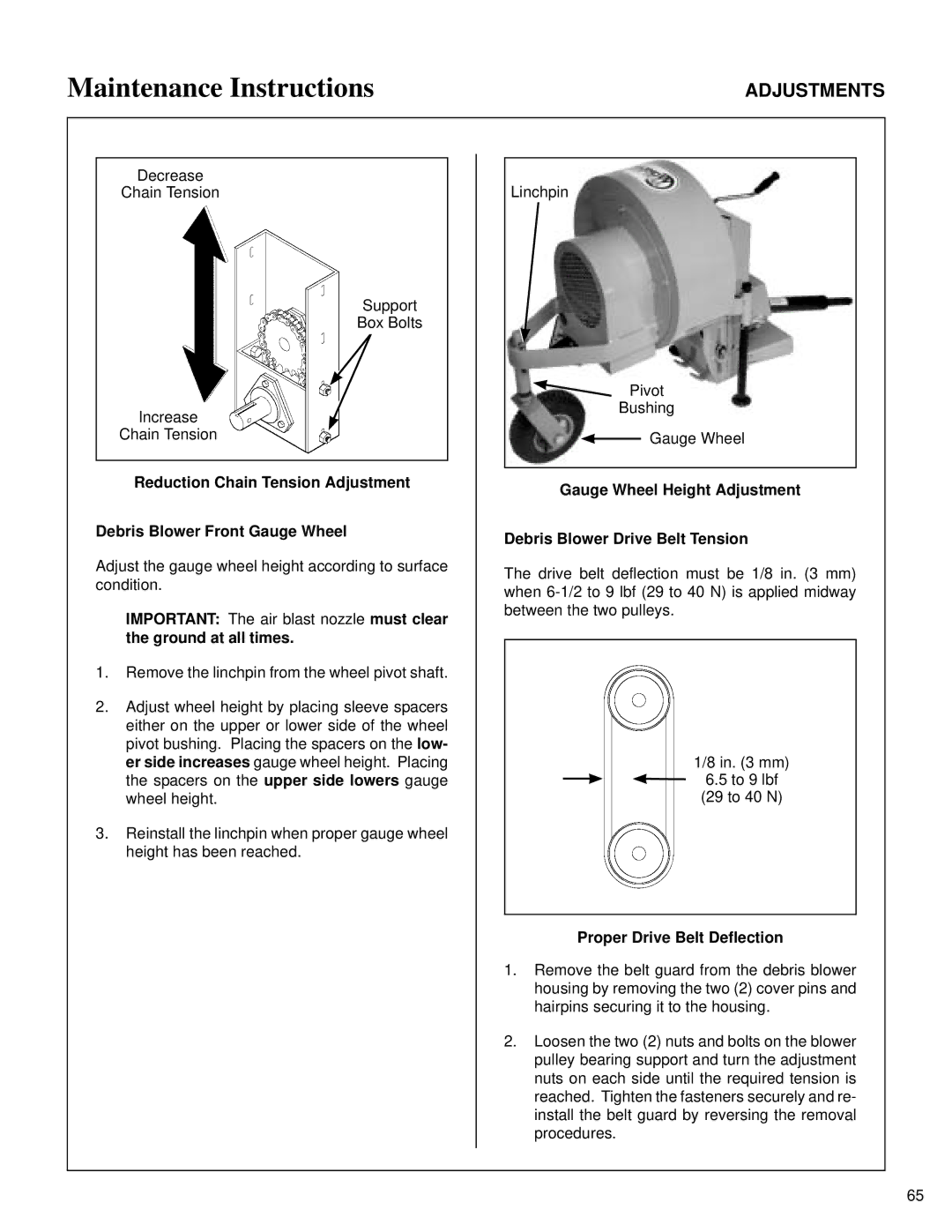

Linchpin

Pivot

Bushing

Gauge Wheel

Gauge Wheel Height Adjustment

Debris Blower Drive Belt Tension

The drive belt deflection must be 1/8 in. (3 mm) when

1/8 in. (3 mm)

6.5 to 9 lbf

(29 to 40 N)

Proper Drive Belt Deflection

1.Remove the belt guard from the debris blower housing by removing the two (2) cover pins and hairpins securing it to the housing.

2.Loosen the two (2) nuts and bolts on the blower pulley bearing support and turn the adjustment nuts on each side until the required tension is reached. Tighten the fasteners securely and re- install the belt guard by reversing the removal procedures.

65