Maintenance Instructions | LUBRICATION |

The gearbox is permanently lubricated (oil filled) and sealed requiring no scheduled lubrication. However, the gearbox oil seal(s) should be checked every 25 hours for indication of an oil leak. If an oil leak is noted, replace the oil seal(s) and relubricate the

1.Remove the gearbox following the procedure described in REPLACING/REPAIRING the

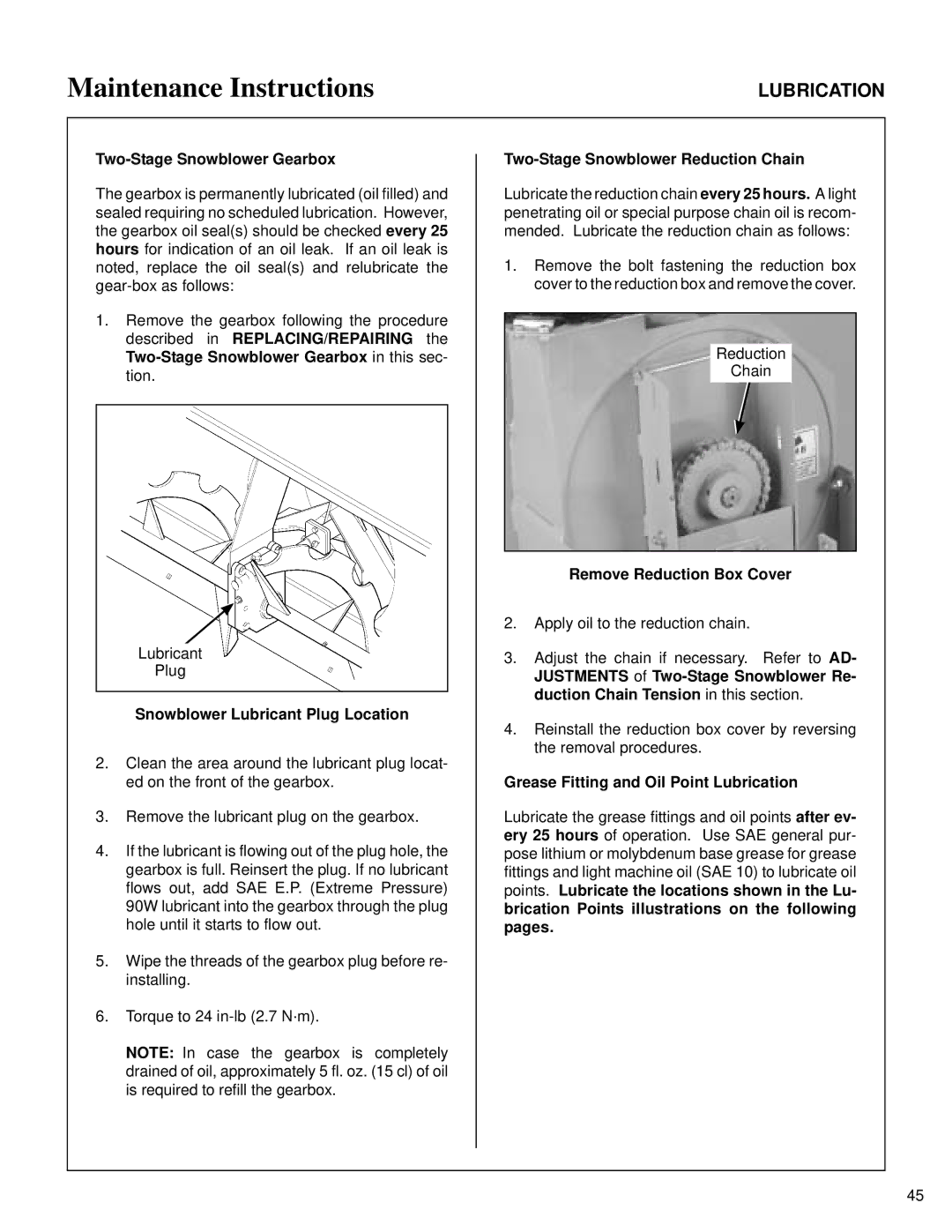

Lubricant

Plug

Snowblower Lubricant Plug Location

2.Clean the area around the lubricant plug locat- ed on the front of the gearbox.

3.Remove the lubricant plug on the gearbox.

4.If the lubricant is flowing out of the plug hole, the gearbox is full. Reinsert the plug. If no lubricant flows out, add SAE E.P. (Extreme Pressure) 90W lubricant into the gearbox through the plug hole until it starts to flow out.

5.Wipe the threads of the gearbox plug before re- installing.

6.Torque to 24

NOTE: In case the gearbox is completely drained of oil, approximately 5 fl. oz. (15 cl) of oil is required to refill the gearbox.

Two-Stage Snowblower Reduction Chain

Lubricate the reduction chain every 25 hours. A light penetrating oil or special purpose chain oil is recom- mended. Lubricate the reduction chain as follows:

1.Remove the bolt fastening the reduction box cover to the reduction box and remove the cover.

Reduction

Chain

Remove Reduction Box Cover

2.Apply oil to the reduction chain.

3.Adjust the chain if necessary. Refer to AD- JUSTMENTS of

4.Reinstall the reduction box cover by reversing the removal procedures.

Grease Fitting and Oil Point Lubrication

Lubricate the grease fittings and oil points after ev- ery 25 hours of operation. Use SAE general pur- pose lithium or molybdenum base grease for grease fittings and light machine oil (SAE 10) to lubricate oil points. Lubricate the locations shown in the Lu- brication Points illustrations on the following pages.

45