� |

| Trolley Operator | |

|

| ||

|

|

|

|

|

|

|

|

Tools Needed: |

| WARNING | |

|

|

| |

Tape Measure |

|

|

|

| OPERATOR MUST BE TESTED | ||

|

| ||

|

| AT TIME OF INSTALLATION AND | |

|

| MONTHLY THEREAFTER TO | |

|

| ENSURE THAT DOOR REVERSES | |

|

| ON CONTACT WITH 2 X 4 BOARD | |

|

| LAID FLAT UNDER THE DOOR. | |

|

| FAILURE TO ADJUST OPERATOR, | |

|

| IF NECESSARY, CAN RESULT IN | |

|

| SEVERE OR FATAL INJURY. IF YOUR | |

|

| OPERATOR IS EQUIPPED WITH A | |

|

| PHOTOELECTRIC EYE SYSTEM, | |

|

| THEN THIS MUST BE TESTED | |

|

| AT THE SAME TIME TO ENSURE | |

|

| THAT DOOR DOES NOT CLOSE | |

|

| AND A CLOSING DOOR OPENS IF | |

|

| PHOTOELECTRIC EYE SYSTEM IS | |

|

| OBSTRUCTED. FAILURE TO MAKE | |

|

| ADJUSTMENTS, IF NECESSARY, | |

|

| CAN RESULT IN SEVERE OR FATAL | |

|

| INJURY. | |

|

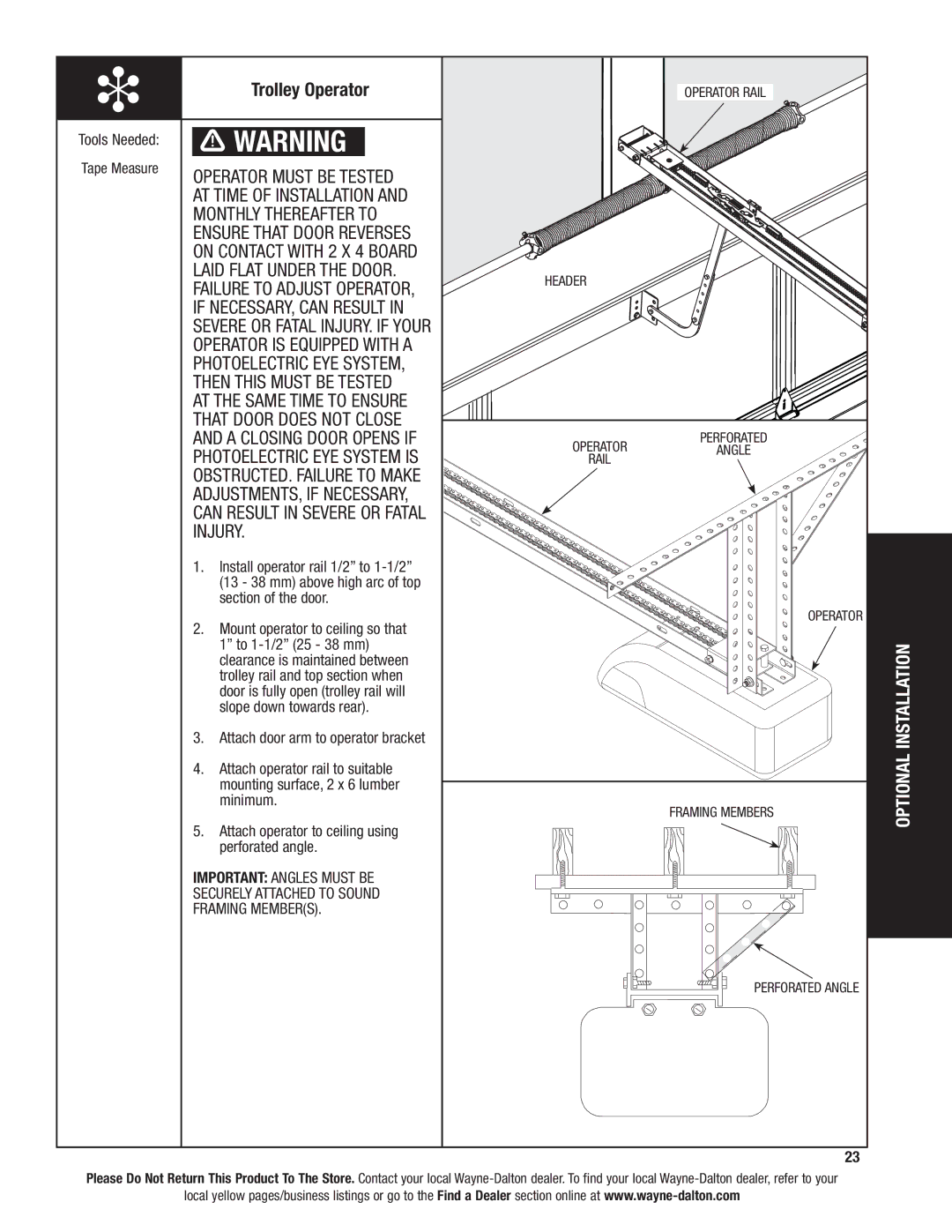

| 1. Install operator rail 1/2” to | |

|

| (13 - 38 mm) above high arc of top | |

|

| section of the door. | |

|

| 2. Mount operator to ceiling so that | |

|

| 1” to | |

|

| clearance is maintained between | |

|

| trolley rail and top section when | |

|

| door is fully open (trolley rail will | |

|

| slope down towards rear). | |

|

| 3. Attach door arm to operator bracket | |

|

| 4. Attach operator rail to suitable | |

|

| mounting surface, 2 x 6 lumber | |

|

| minimum. | |

|

| 5. Attach operator to ceiling using | |

|

| perforated angle. | |

|

| IMPORTANT: Angles must be | |

|

| securely attached to sound | |

|

| framing member(s). | |

OPERATOR RAIL

HEADER

perforated

OPERATORangle rail

OPERATOR

FRAMING MEMBERS

PERFORATED ANGLE

optional INSTALLATION

23

Please Do Not Return This Product To The Store. Contact your local

local yellow pages/business listings or go to the Find a Dealer section online at