| Rear Support Continued... |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

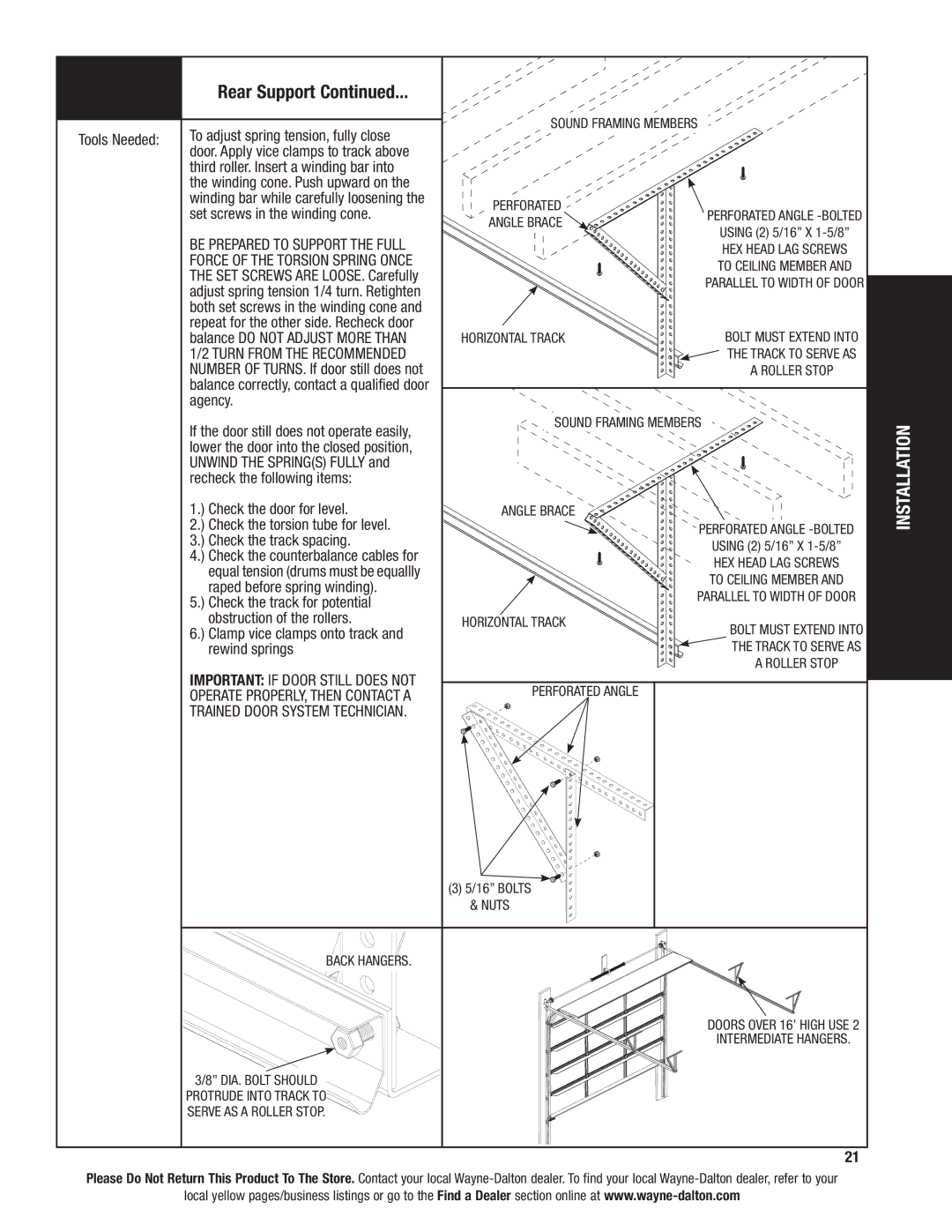

| Sound Framing Members |

|

|

| ||||

Tools Needed: | To adjust spring tension, fully close | |||||||||||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

| ||||

| door. Apply vice clamps to track above |

|

|

|

|

|

|

|

|

|

|

| ||

| third roller. Insert a winding bar into |

|

|

|

|

|

|

|

|

|

|

| ||

| the winding cone. Push upward on the |

|

|

|

|

|

|

|

|

|

|

| ||

| winding bar while carefully loosening the |

|

|

|

|

|

|

|

|

|

|

| ||

|

| perforated |

|

|

|

|

|

| ||||||

| set screws in the winding cone. |

|

|

| perforated ANGLE | |||||||||

|

| ANGLE BRACE |

|

| ||||||||||

|

|

|

|

|

|

|

| USING (2) 5/16” X | ||||||

| BE PREPARED TO SUPPORT THE FULL |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

| HEX HEAD LAG SCREWS | ||||

| FORCE OF THE TORSION SPRING ONCE |

|

|

|

|

|

|

|

|

| TO CEILING MEMBER AND | |||

| THE SET SCREWS ARE LOOSE. Carefully |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| PARALLEL TO WIDTH OF DOOR | ||||||

| adjust spring tension 1/4 turn. Retighten |

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| |||

| both set screws in the winding cone and |

|

|

|

|

|

|

|

|

|

|

| ||

| repeat for the other side. Recheck door |

|

|

|

|

|

|

|

|

| BOLT MUST EXTEND INTO | |||

| balance DO NOT ADJUST MORE THAN | HORIZONTAL TRACK |

|

| ||||||||||

| 1/2 TURN FROM THE RECOMMENDED |

|

|

|

|

|

|

|

|

| THE TRACK TO SERVE AS | |||

| NUMBER OF TURNS. If door still does not |

|

|

|

|

|

|

|

|

| A ROLLER STOP | |||

| balance correctly, contact a qualified door |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| agency. |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |||||

| If the door still does not operate easily, |

|

|

|

| Sound Framing Members |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| |||

| lower the door into the closed position, |

|

|

|

|

|

|

|

|

|

|

| ||

| UNWIND THE SPRING(S) FULLY and |

|

|

|

|

|

|

|

|

|

|

| ||

| recheck the following items: |

|

|

|

|

|

|

|

|

|

|

| ||

| 1.) Check the door for level. |

|

|

|

|

|

|

| ||||||

|

|

| ANGLE BRACE |

|

|

|

|

| ||||||

| 2.) Check the torsion tube for level. |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| perforated ANGLE |

| |||||

|

|

|

|

|

|

|

|

| ||||||

| 3.) Check the track spacing. |

|

|

|

|

|

|

|

| USING (2) 5/16” X |

| |||

| 4.) Check the counterbalance cables for |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| HEX HEAD LAG SCREWS |

| |||

| equal tension (drums must be equallly |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| TO CEILING MEMBER AND |

| ||||

| raped before spring winding). |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| PARALLEL TO WIDTH OF DOOR |

| |||||

| 5.) Check the track for potential |

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

| |||

| obstruction of the rollers. | HORIZONTAL TRACK |

|

| BOLT MUST EXTEND INTO | |||||||||

| 6.) Clamp vice clamps onto track and |

|

|

|

|

|

|

|

|

| ||||

| rewind springs |

|

|

|

|

|

|

|

|

| THE TRACK TO SERVE AS | |||

| IMPORTANT: If door still does not |

|

|

|

|

|

|

|

|

|

| A ROLLER STOP | ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| PERFORATED ANGLE |

|

|

|

| ||||||

| operate properly, then contact a |

|

|

|

|

|

| |||||||

| trained door system technician. |

|

|

|

|

|

|

|

|

|

|

| ||

(3)5/16” BOLTS

&NUTS

back hangers.

Doors over 16’ high use 2 intermediate hangers.

3/8” dia. Bolt should

protrude into track to serve as a roller stop.

21

INSTALLATION

Please Do Not Return This Product To The Store. Contact your local

local yellow pages/business listings or go to the Find a Dealer section online at