| Preparing the Opening | Note: For other drums, mounting conditions, lifts, and options, | |||||

| Continued | consult your |

| ||||

Tools Needed: |

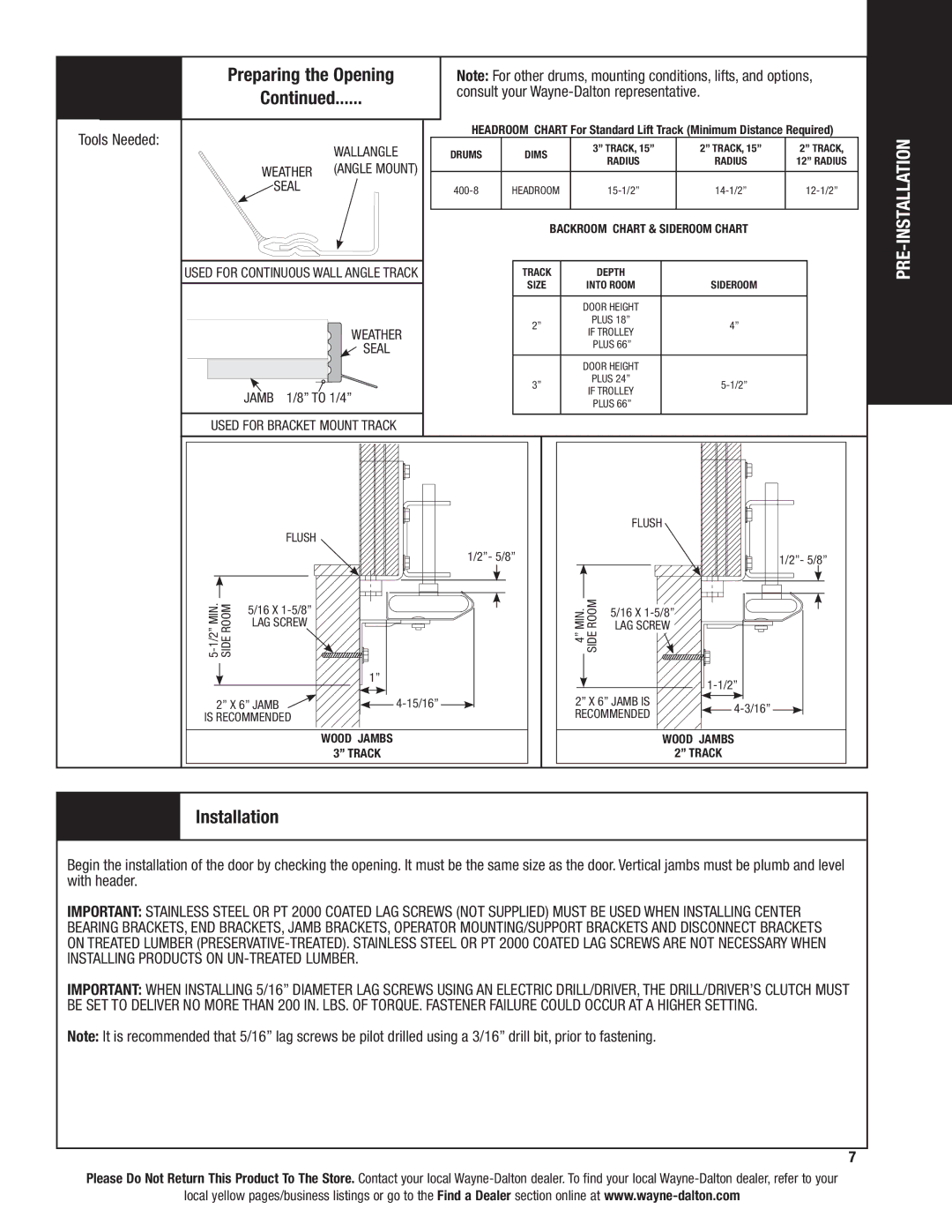

| HEADROOM CHART For Standard Lift Track (Minimum Distance Required) | |||||

Wallangle | DRUMS | DIMS | 3” TRACK, 15” | 2” TRACK, 15” | 2” TRACK, | ||

| |||||||

| weather (angle mount) |

|

| RADIUS | RADIUS | 12” RADIUS | |

|

|

|

|

|

| ||

| seal | HEADROOM | |||||

|

|

| BACKROOM CHART & SIDEROOM CHART |

| |||

| Used for Continuous wall angle track |

| TRACK | DEPTH |

|

| |

|

|

| SIZE | INTO ROOM | SIDEROOM |

| |

|

|

|

| DOOR HEIGHT |

|

| |

|

|

| 2” | PLUS 18” | 4” |

| |

| weather |

| IF TROLLEY |

| |||

|

|

|

|

| |||

| seal |

|

| PLUS 66” |

|

| |

|

|

|

| DOOR HEIGHT |

|

| |

|

|

| 3” | PLUS 24” |

| ||

| jamb 1/8” to 1/4” |

| IF TROLLEY |

| |||

|

|

|

|

| |||

|

|

| PLUS 66” |

|

| ||

|

|

|

|

|

| ||

Used for bracket mount track

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FLUSH |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| FLUSH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/2”- 5/8” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/2”- 5/8” |

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5/16 X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| MIN.4” ROOMSIDE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5/16 X |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| LAG SCREW |

|

| 1” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LAG SCREW |

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

| 2” X 6” JAMB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2” X 6” JAMB IS |

| ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||||||||||||

|

| IS RECOMMENDED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RECOMMENDED |

|

|

|

|

|

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

| WOOD JAMBS |

|

|

|

|

|

|

|

| WOOD JAMBS |

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

| 3” TRACK |

|

|

|

|

|

|

|

|

| 2” TRACK |

| |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation

Begin the installation of the door by checking the opening. It must be the same size as the door. Vertical jambs must be plumb and level with header.

Important: STAINLESS STEEL OR PT 2000 COATED LAG SCREWS (NOT SUPPLIED) MUST be USED When INSTALLING CENTER bearing brackets, END brackets, jamb brackets, OPERATOR MOUNTING/SUPPORT brackets AND DISCONNECT brackets ON TREATED Lumber

Important: when installing 5/16” diameter lag screws using an electric drill/driver, the drill/driver’s clutch must be set to deliver no more than 200 In. lbs. Of torque. Fastener failure could occur at a higher setting.

Note: It is recommended that 5/16” lag screws be pilot drilled using a 3/16” drill bit, prior to fastening.

7

PRE-INSTALLATION

Please Do Not Return This Product To The Store. Contact your local

local yellow pages/business listings or go to the Find a Dealer section online at