MACHINE CONTROLLER

The Machine Controller interprets the consumer inputs from the keyswitch pads to operate the cycle selected. The Machine Controller interfaces with the Motor Controller to operate the Drive motor and Pump motor through their vari- ous functions during the cycle. The Machine Controller also directly operates the water fill and dispenser solenoids, interprets the thermistor readings, lid switch condition, as well as the position of the contacts in the Operating and Flood Pressure switches.

Fig.

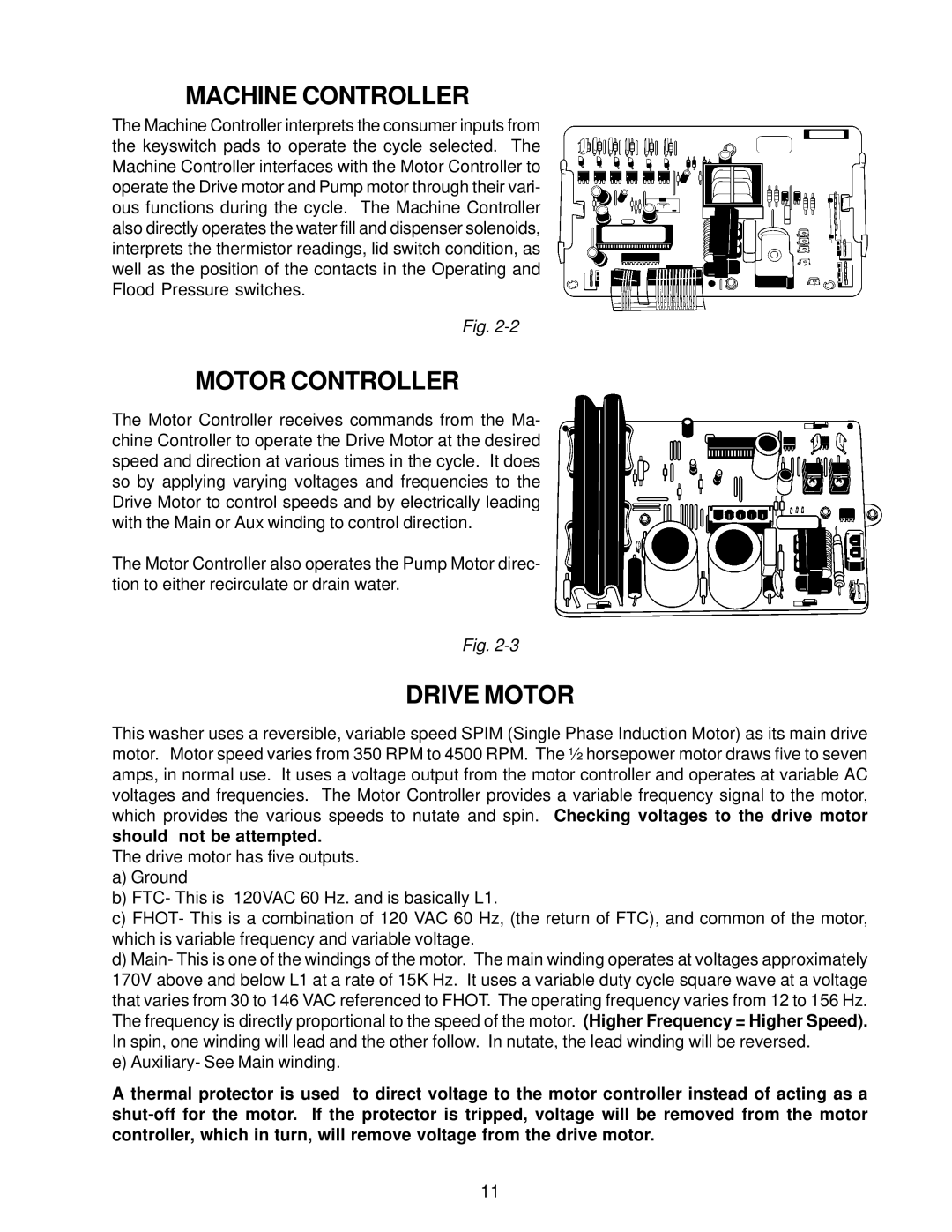

MOTOR CONTROLLER

The Motor Controller receives commands from the Ma- chine Controller to operate the Drive Motor at the desired speed and direction at various times in the cycle. It does so by applying varying voltages and frequencies to the Drive Motor to control speeds and by electrically leading with the Main or Aux winding to control direction.

The Motor Controller also operates the Pump Motor direc- tion to either recirculate or drain water.

Fig.

DRIVE MOTOR

This washer uses a reversible, variable speed SPIM (Single Phase Induction Motor) as its main drive motor. Motor speed varies from 350 RPM to 4500 RPM. The ½ horsepower motor draws five to seven amps, in normal use. It uses a voltage output from the motor controller and operates at variable AC voltages and frequencies. The Motor Controller provides a variable frequency signal to the motor, which provides the various speeds to nutate and spin. Checking voltages to the drive motor should not be attempted.

The drive motor has five outputs.

a)Ground

b)FTC- This is 120VAC 60 Hz. and is basically L1.

c)FHOT- This is a combination of 120 VAC 60 Hz, (the return of FTC), and common of the motor, which is variable frequency and variable voltage.

d)Main- This is one of the windings of the motor. The main winding operates at voltages approximately 170V above and below L1 at a rate of 15K Hz. It uses a variable duty cycle square wave at a voltage that varies from 30 to 146 VAC referenced to FHOT. The operating frequency varies from 12 to 156 Hz. The frequency is directly proportional to the speed of the motor. (Higher Frequency = Higher Speed). In spin, one winding will lead and the other follow. In nutate, the lead winding will be reversed.

e)Auxiliary- See Main winding.

A thermal protector is used to direct voltage to the motor controller instead of acting as a

11