11.Remove the spanner nut. Once this is done, the universal joint assembly can be lifted from the basket.

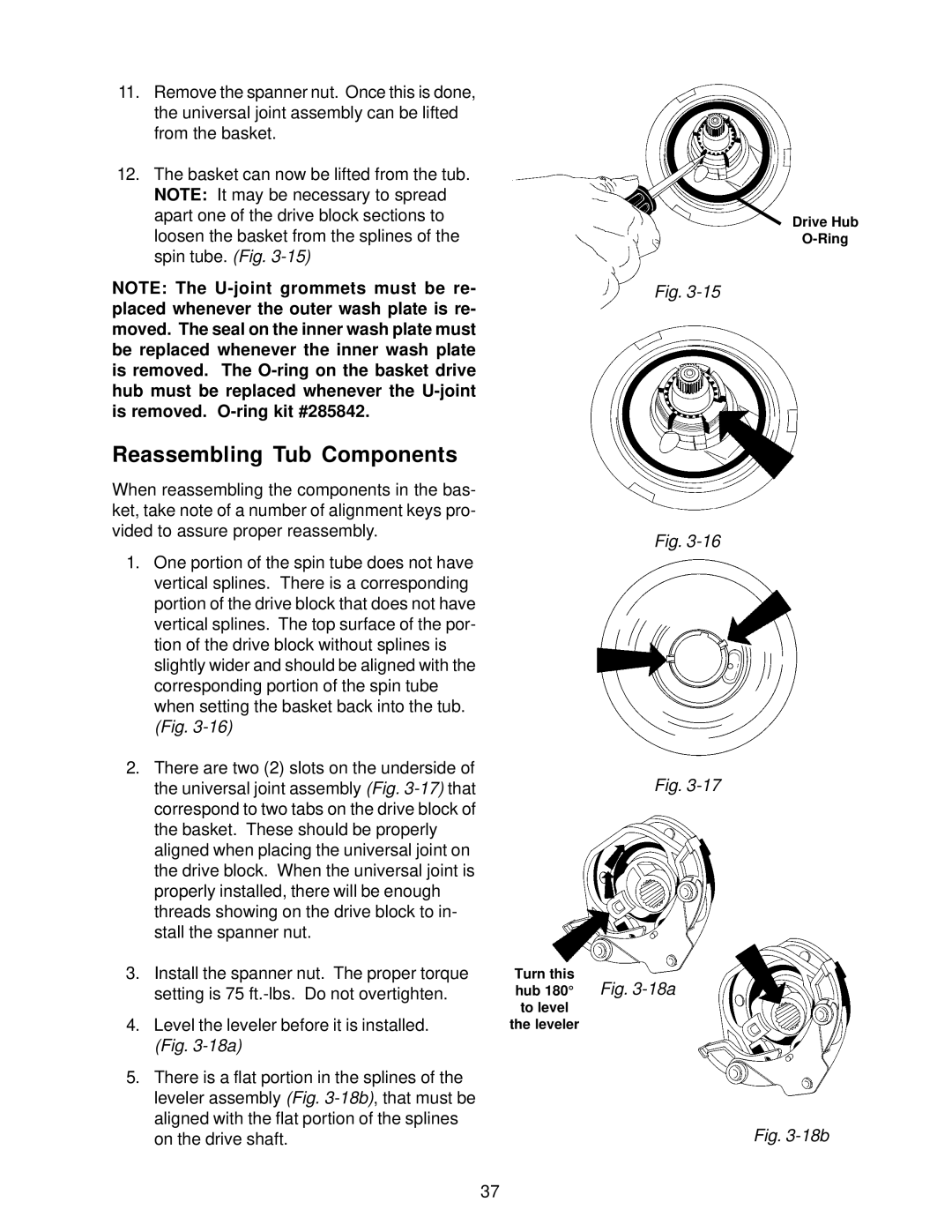

12.The basket can now be lifted from the tub. NOTE: It may be necessary to spread apart one of the drive block sections to loosen the basket from the splines of the spin tube. (Fig.

NOTE: The

Reassembling Tub Components

When reassembling the components in the bas- ket, take note of a number of alignment keys pro- vided to assure proper reassembly.

1.One portion of the spin tube does not have vertical splines. There is a corresponding portion of the drive block that does not have vertical splines. The top surface of the por- tion of the drive block without splines is slightly wider and should be aligned with the corresponding portion of the spin tube when setting the basket back into the tub. (Fig.

2.There are two (2) slots on the underside of the universal joint assembly (Fig.

3.Install the spanner nut. The proper torque setting is 75

4.Level the leveler before it is installed. (Fig.

5.There is a flat portion in the splines of the leveler assembly (Fig.

Drive Hub

Fig.

Fig.

Fig.

Turn this

hub 180° Fig.

the leveler

Fig. 3-18b

37