entire control system.

The control unit is located below the operat- ing panel. To access the fuses the cover on the left side of the foot compartment must be removed in advance.

ÎTurn out the fastening screws at the up- per end of the cover.

ÎRemove cover.

ÎReplace fuse.

ÎReplace cover.

Note

The population of fuses is displayed on the inner side of the cover.

Fault indication

The display shows the existing faults at in- tervals of 4 seconds (example:

Fault scrubbing funktion H1/022

If the faults continue to be displayed on the console even after 4 seconds, then proceed as follows:

ÎSet main switch to “0”.

ÎWait till the text on the display has dis- appeared.

ÎSet main switch to “1”.

Carry out the troubleshooting measures in the given sequence only if the fault occurs again. The key switch must be in position "0" and the battery plug must have been pulled out.

ÎIf the fault cannot be repaired, call cus- tomer service and mention the fault code(s) (H1/022 in the example).

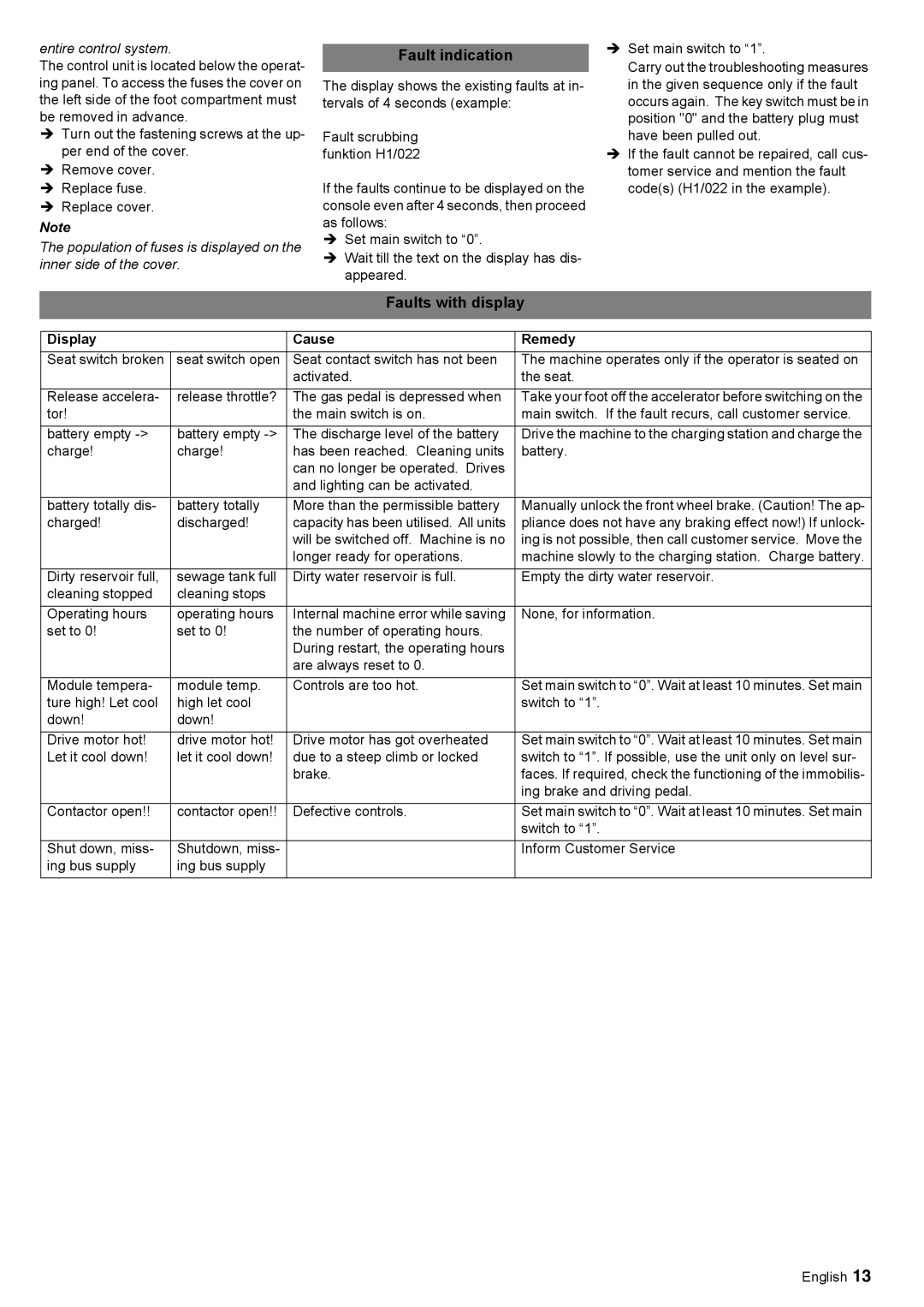

Faults with display

Display |

| Cause | Remedy |

Seat switch broken | seat switch open | Seat contact switch has not been | The machine operates only if the operator is seated on |

|

| activated. | the seat. |

|

|

|

|

Release accelera- | release throttle? | The gas pedal is depressed when | Take your foot off the accelerator before switching on the |

tor! |

| the main switch is on. | main switch. If the fault recurs, call customer service. |

|

|

|

|

battery empty | battery empty | The discharge level of the battery | Drive the machine to the charging station and charge the |

charge! | charge! | has been reached. Cleaning units | battery. |

|

| can no longer be operated. Drives |

|

|

| and lighting can be activated. |

|

battery totally dis- | battery totally | More than the permissible battery | Manually unlock the front wheel brake. (Caution! The ap- |

charged! | discharged! | capacity has been utilised. All units | pliance does not have any braking effect now!) If unlock- |

|

| will be switched off. Machine is no | ing is not possible, then call customer service. Move the |

|

| longer ready for operations. | machine slowly to the charging station. Charge battery. |

|

|

|

|

Dirty reservoir full, | sewage tank full | Dirty water reservoir is full. | Empty the dirty water reservoir. |

cleaning stopped | cleaning stops |

|

|

|

|

|

|

Operating hours | operating hours | Internal machine error while saving | None, for information. |

set to 0! | set to 0! | the number of operating hours. |

|

|

| During restart, the operating hours |

|

|

| are always reset to 0. |

|

|

|

|

|

Module tempera- | module temp. | Controls are too hot. | Set main switch to “0”. Wait at least 10 minutes. Set main |

ture high! Let cool | high let cool |

| switch to “1”. |

down! | down! |

|

|

|

|

|

|

Drive motor hot! | drive motor hot! | Drive motor has got overheated | Set main switch to “0”. Wait at least 10 minutes. Set main |

Let it cool down! | let it cool down! | due to a steep climb or locked | switch to “1”. If possible, use the unit only on level sur- |

|

| brake. | faces. If required, check the functioning of the immobilis- |

|

|

| ing brake and driving pedal. |

|

|

|

|

Contactor open!! | contactor open!! | Defective controls. | Set main switch to “0”. Wait at least 10 minutes. Set main |

|

|

| switch to “1”. |

|

|

|

|

Shut down, miss- | Shutdown, miss- |

| Inform Customer Service |

ing bus supply | ing bus supply |

|

|

|

|

|

|

English 13