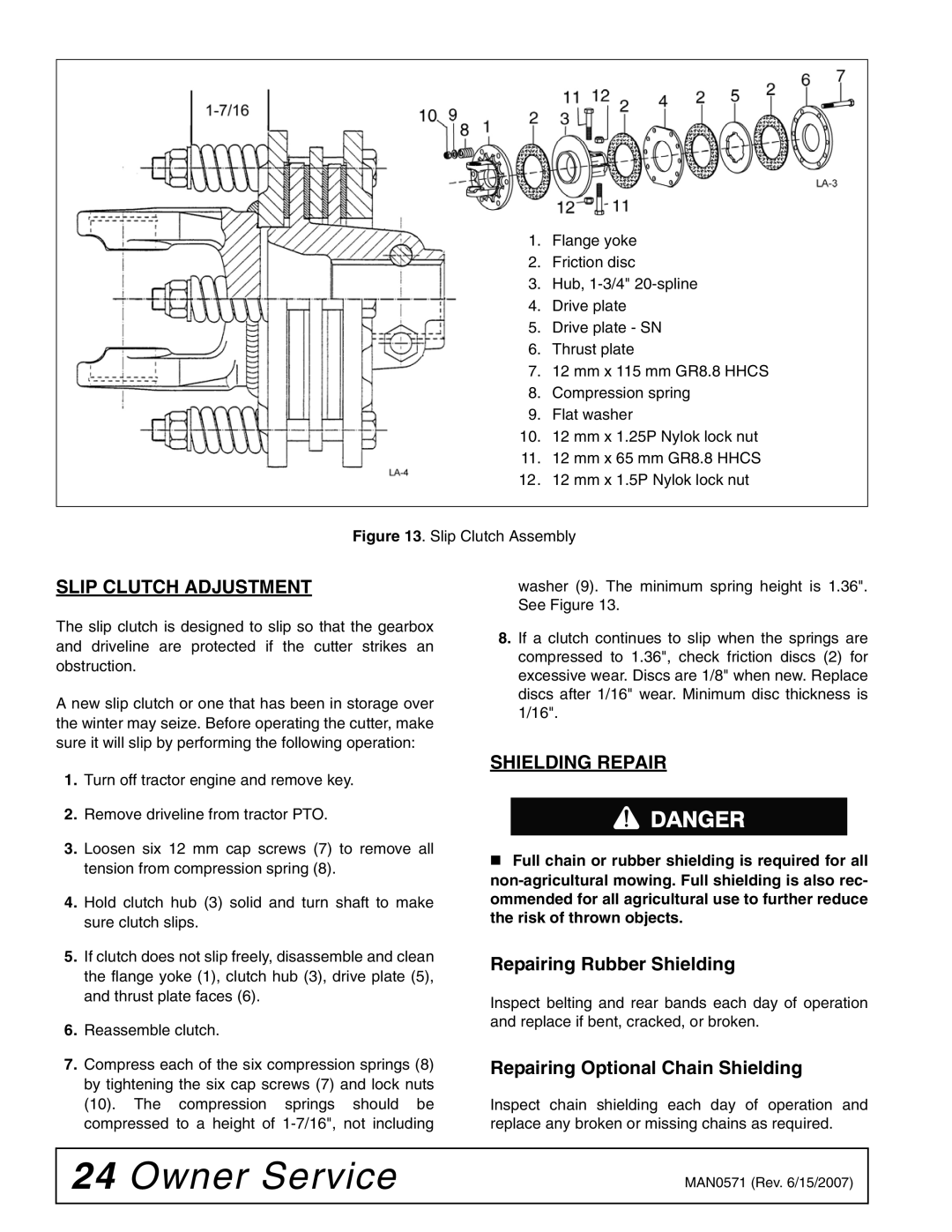

1.Flange yoke

2.Friction disc

3.Hub,

4.Drive plate

5.Drive plate - SN

6.Thrust plate

7.12 mm x 115 mm GR8.8 HHCS

8.Compression spring

9.Flat washer

10.12 mm x 1.25P Nylok lock nut

11.12 mm x 65 mm GR8.8 HHCS

12.12 mm x 1.5P Nylok lock nut

Figure 13. Slip Clutch Assembly

SLIP CLUTCH ADJUSTMENT

The slip clutch is designed to slip so that the gearbox and driveline are protected if the cutter strikes an obstruction.

A new slip clutch or one that has been in storage over the winter may seize. Before operating the cutter, make sure it will slip by performing the following operation:

washer (9). The minimum spring height is 1.36". See Figure 13.

8.If a clutch continues to slip when the springs are compressed to 1.36", check friction discs (2) for excessive wear. Discs are 1/8" when new. Replace discs after 1/16" wear. Minimum disc thickness is 1/16".

1.Turn off tractor engine and remove key.

2.Remove driveline from tractor PTO.

3.Loosen six 12 mm cap screws (7) to remove all tension from compression spring (8).

4.Hold clutch hub (3) solid and turn shaft to make sure clutch slips.

5.If clutch does not slip freely, disassemble and clean the flange yoke (1), clutch hub (3), drive plate (5), and thrust plate faces (6).

6.Reassemble clutch.

7.Compress each of the six compression springs (8) by tightening the six cap screws (7) and lock nuts (10). The compression springs should be compressed to a height of

SHIELDING REPAIR

Full chain or rubber shielding is required for all

Repairing Rubber Shielding

Inspect belting and rear bands each day of operation and replace if bent, cracked, or broken.

Repairing Optional Chain Shielding

Inspect chain shielding each day of operation and replace any broken or missing chains as required.

24 Owner Service | MAN0571 (Rev. 6/15/2007) |

|

|