Torque Hardware |

|

|

| NOTICE | ||

Torque all hardware to specifications listed below. |

| ■ Check torque value of mount hardware after | ||||

|

|

|

| 10 hours of operation and again after every 50 | ||

|

|

|

| hours of operation. | ||

|

|

|

|

| ||

|

| TORQUE SPECIFICATIONS |

|

| ||

| Ref. | Cap Screw | Qty | Wrench | Required Torque |

|

|

|

|

| Size |

|

|

| 7 | M20 x 2.5P x 40 mm | 2 | 30 mm | 244 |

|

| 5 | M20 x 2.5P x 50 mm | 8 | 30 mm | 244 |

|

| 8 | M20 x 2.5P x 70 mm | 4 | 30 mm | 244 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Install Weather Cap on Exhaust Pipe

NOTE: After the hydraulics and loader are install on the tractor, check the clearance between the top of the exhaust pipe and the loader boom when the loader is raised. If there is interference, a weather cap will need to be installed.

1.Remove exhaust pipe from the tractor. Save hardware for later use.

2.Remove approximately

3.Attach exhaust pipe to the tractor. Make sure that the support flange on the exhaust pipe is between the tractor and the support bracket as shown in page 6. Secure using hardware previously removed.

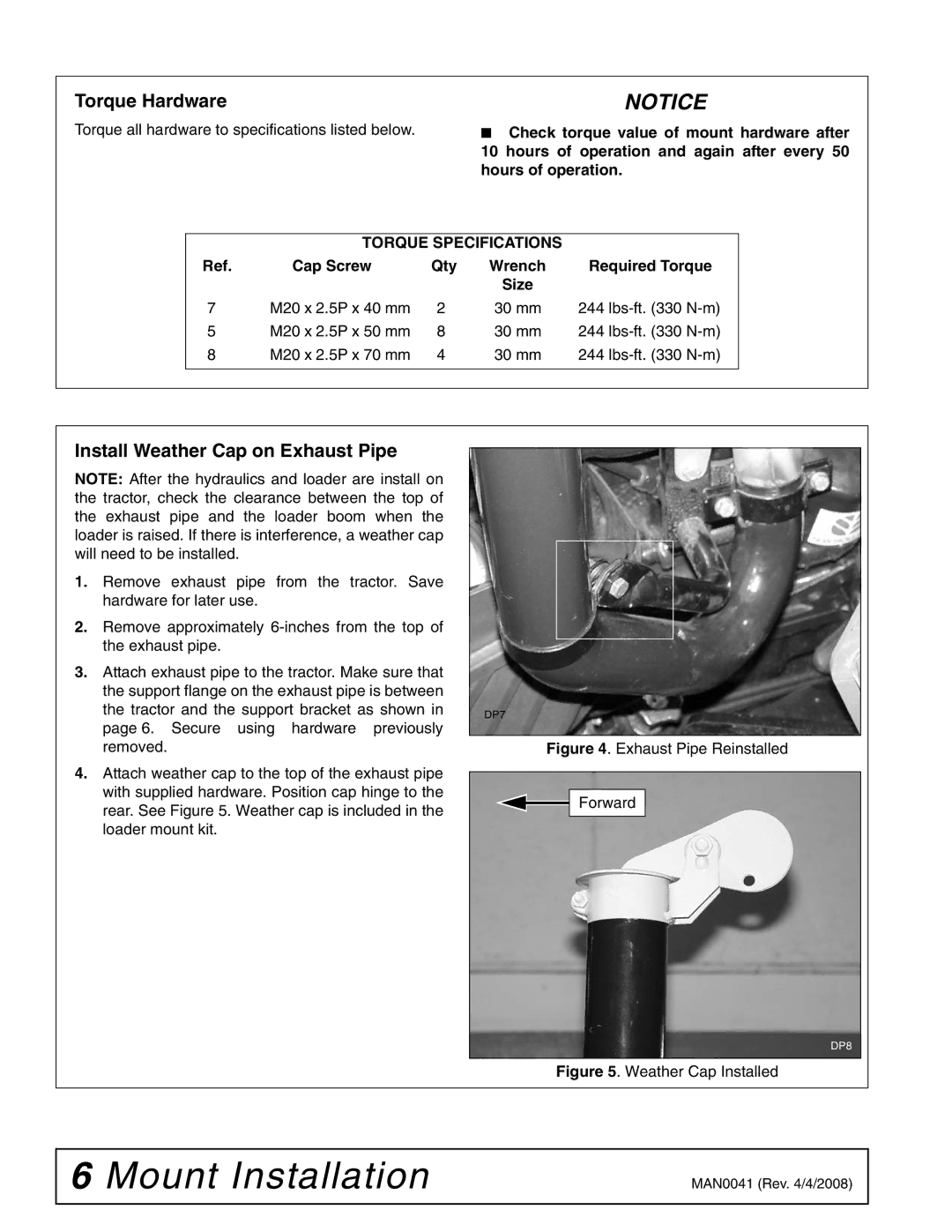

4.Attach weather cap to the top of the exhaust pipe with supplied hardware. Position cap hinge to the rear. See Figure 5. Weather cap is included in the loader mount kit.

DP7

Figure 4. Exhaust Pipe Reinstalled

Forward

DP8

Figure 5. Weather Cap Installed

6 Mount Installation | MAN0041 (Rev. 4/4/2008) |

|

|