SW Series Inverter/Chargers

2001 Xantrex Technology, Inc Telephone 360/435-8826

Product Materials Package

2001 Xantrex Technology, Inc Telephone 360/435-8826

Table of Contents

Operation

128

135

137

Index of Figures

131

Table of Contents Index of Tables

Important Safety Instructions

General Precautions

Special Notices

Personal Precautions

Important Safety Instructions

Introduction

Introduction

Unit Identification

Model Number

Unit Identification

CONTROLS, Indicators and Components

Control Panel

Display

Reset to Factory Defaults Button

LED Status Indicators

Contrast Control

Menu Buttons

Error Red

AC1 in Good Green

AC2 in Good Green

Bulk Yellow

AC Side

Remote Port

Stacking Port

INVERTER/CHARGER Circuit Breaker

Internal Components and Indicators

LED Indicators

BTS Port

AC Terminal Block

Battery Terminals DC Equipment Ground

AC Safety Ground

Auxiliary and Generator Control Relay Connectors

DC Side

Installation

Quick Install

Complete Install

Unpacking

Location

AC Wiring

Ventilation

AC Input and Output Connections

AC Terminal Block # Wire Color

AC OUT

AC Connections

Purpose

AC Installation Guidelines

Important Precaution

External Transfer Relays

VAC Ground Fault Interrupt Outlets GFI’S

Pass & Seymor

DC Wiring

Battery Cable Sizing

Inverter Model Typical AMPS1 NEC To 3 Feet

To 5 FT

DC Disconnect and Overcurrent Protection

Cable Size Required

Rating Maximum Conduit Breaker Size Free AIR

Maximum Fuse Size

Battery Cable Connections

Installation Procedure Battery Cables

Control Wiring

GEN Control Wiring

AUX Relay Wiring

Remote Control Wiring

System Grounding

Equipment or Chassis Grounds

Grounding ELECTRODES/GROUND Rods

Bonding the Grounding System

NEUTRAL-TO-GROUND Bond Switching RV and Marine Applications

NEUTRAL-TO-GROUND

AC Source

AC Source

Grounding VS. Lightning

ONE Ground for ALL Equipment

Keep Equipment Close Together

Installation

Functional Test

Functional Test

Menu System

Overview

User Menu MAP

Push buttons on

Setup Menu MAP

FLT Sell SLT LBX

User Menu

Menu Headings

Inverter Mode 1 Menu Heading

Generator Mode 2 Menu Heading

Information Display

Gen under/over SpeedNO

Trace Engineering 3 Menu Heading

5916 195th St NE Arlington, WA 98223 USA Fax

Meters 4 Menu Heading

Error Causes 5 Menu Heading

High Battery VoltageNO

Generator Timer 7 Menu Heading

Time of DAY 6 Menu Heading

Setup Menu

Inverter Setup 9 Menu Heading

VDC models Range 08.0 to

Battery Charging 10 Menu Heading

Battery temperature if the BTS sensor is installed

AC Inputs 11 Menu Headings

GEN Auto Start Setup 12 Menu Heading

GEN Starting Details 13 Menu Heading

Auxiliary Relays 14 Menu Heading

VDC Models Range 00.1 to

Bulk Charge Trigger Timer 15 Menu Heading

LOW Battery Transfer 16 Menu Heading

Battery Selling 17 Menu Heading

Grid Usage Timer 18 Menu Heading

Information File Battery 19 Menu Heading

Menu System

Operation

Theory of Operation

Trace SW Series Inverter Output Waveform

Power VS. Efficiency

Efficiency

Inverter Capacity VS Temperature

Power Capacity

Temperature C

Total

Additional Features

Operating Modes

Inverter Mode

Search Mode Control

Batterydc Inverter AC Loads

Setting Search Mode Watts

LOW Battery Protection

Setting Search Mode Spacing

Adjusting the LOW Battery Protection

Charger Mode

AC Source Charger Battery

Three Stage Charging Process

Battery Temperature Sensor BTS

Charger only Operation

AC Input Requirements

Input AC Voltage

Recommended Battery Charger Settings

Delay Period

AC Current Level

Frequency

Typical Bulk and Float Setpoints for Common Battery Types

Equalizing Batteries Unsealed or Vented Batteries only

Operation

INVERTER/CHARGER Mode

Utility Grid Generator INVERTER/ Charger AC Loads Battery

Transferring Upon Availability of AC Power

Transferring Based on Battery Voltage

Transfer Time

Generator Support Mode

Generator Inverter Charger Battery AC Loads

Generator SUPPORT/OVERLOAD Protection

VAC VS /240 VAC Generators

Automatic Generator Control Mode

Generator Control INVERTER/ Charger AC Loads Battery

GEN Control Relays

Generator Starting Scenarios

Automatically

Generator Starting and Stopping Configurations

Manually

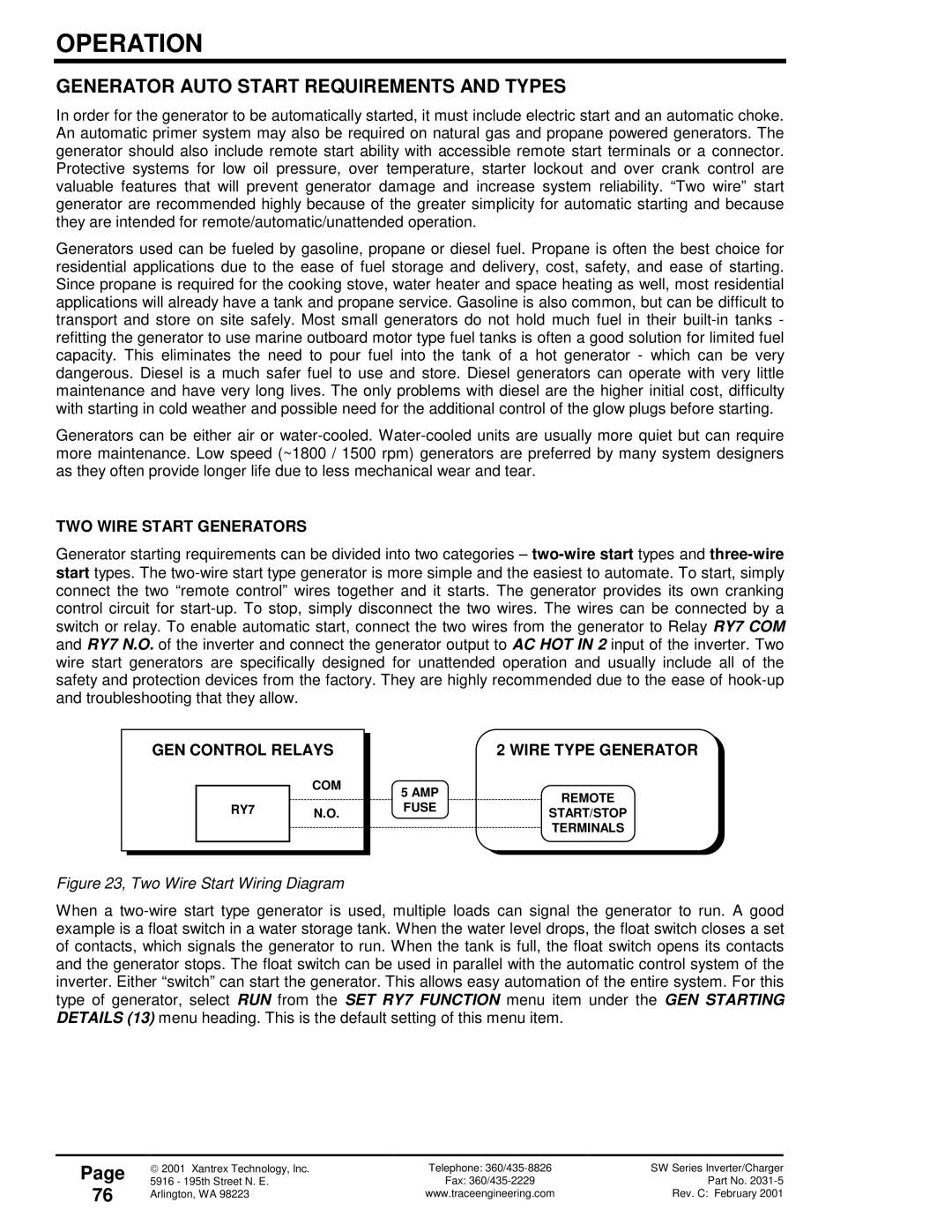

TWO Wire Start Generators

Wire Type Generator

Generator Auto Start Requirements and Types

GEN Control Relays

THREE-WIRE Start Generators

Honda Type Generator

TO-2 Wire Converters

Generator Control Sequence

Generator Error Causes

Generator Stop Cool Down Period

Equalization CHARGING, Automatic Generator Control System

Utility Backup Mode

Using SLT Mode Silent Mode

Battery Requirements

Utility SUPPORT/OVERLOAD Protection

Utility Interactive Mode

Utility Grid

KWh Meter

Theory of Operation

Utility Interactive Islanding Protection

Selling Power from a DC Charging Source

Time DC Volts

Selling Power Stored in the Batteries

Time

Battery Regulation Level Sell Mode

Utility Interactive Operation with Utility Backup

Backup of Critical AC

Utility Interactive

LINE-TIE System with

Overvoltage Protection for the Battery in Sell Mode

Battery Bank

Solar Array

SW Series

Energy Management Mode

INVERTER/ Charger Battery AC Loads

Operation

Peak Load Shaving Mode

Brief

LOW Battery Transfer LBX Mode

Utility Grid kWH Meter

Operation

Using Multiple Inverters

INPUT/OUTPUT Bypass Breaker Switch 240 VAC Loads

Series Stacked Operation

Generator Control Settings

Parallel Stacked Operation

240 VAC/60 HZ only Electrical Systems

Battery Charging with Multiple Inverters

Automatic Generator Control with Multiple Inverters

Operation

Battery Type

Selection of Battery Type

Technical Information

Nicad and Nickel Iron Nife Battery

100

Sealed Lead Acid Batteries

Battery Sizing

Estimating Battery Requirements

101

Typical Appliance Watts

Battery Bank Sizing

Example

102

Worksheet

103

Battery Care and Maintenance

104

Monthly Maintenance

Battery State of Charge

105

Battery Installation

Battery Enclosures

Battery Temperature

106

Battery HOOK-UP Configurations

Series Connection

107

48V Inverter

Parallel Connection

Series Parallel Connection

108

12V Inverter

Total Battery Capacity

109

24V Inverter

= 200 Amp Hours

Battery Cable Inductance

Distance Between Battery Cables Inductance Micro-Henries

110

Applications

Resistive Loads

Inductive Loads

111

Troubleshooting Guide

Problem

Solution

112

Problem Indication Solution

113

Indication Solution

114

INVERTER/CHARGER Terminology

115

Digital VoltMeter DVM

116

AC Waveforms

117

Stacking

Specifications and Features 60 Hz Models

118

Specifications and Features 50 Hz Models

119

Dimensions

120

Installation Diagrams

121

122

User Settings Worksheets

User Menu

123

SW Series Inverter/Charger Model SW

Setup Menu 12 VDC 120 VAC/60HZ Models

124

Setup Menu 24 VDC 120 VAC/60HZ Models

125

Setup Menu 48 VDC 120 VAC/60HZ Models

126

127

Appendix

Options

Swrc

Swca

Other Products

Reference Tables and Graphs

130

AWG Wire Size

131

132

Inverter Model

Cable Size Required Free AIR

Knockout or Hole Diameter Inches

Preparation for Storage

133

Interior Storage

Exterior Storage

134

WARRANTY/REPAIR Information

Limited Warranty

Warranty Registration

Life Support Policy

Warranty or Repair Service Required

136

Index

137

Fusing 25, 74

138

139

Equalization Charging 38, 47, 68, 79, 80

Menu 4 Meters Menu 5 Error Causes

140

141

Set Input Lower Limit VAC 71, 72

142