036-21410-001-A-0502

ECONOMIZER / MOTORIZED DAMPER FIXED OUTDOOR INTAKE AIR AND POWER EXHAUST RAIN HOODS (See detail Y)

BLOWER | BLOWER MOTOR | BLOWER | |

COMPARTMENT | ACCESS | ||

ACCESS | |||

ACCESS |

| ||

|

| ||

(Auxillary) |

|

| |

DOT PLUG |

| ||

|

| ||

(For pressure |

|

| |

drop reading) |

|

| |

GAS OR |

|

| |

ELECTRIC |

|

| |

HEAT ACCESS |

| ||

VENT AIR |

|

| |

OUTLET |

|

| |

HOODS |

|

| |

COMBUSTION

AIR INLET HOOD

(C) GAS

SUPPLY

ENTRY ![]()

21.00

5

COMPRESSOR ACCESS | |

| (See detail X) |

COIL

GUARD

KIT

CONDENSER

COILS

(A)CONTROL WIRING

92ENTRY

DISCONNECT

CONTROL BOX | |

ACCESS | |

| |

35 |

|

| |

| RETURN |

33 | AIR |

SWITCH

LOCATION

(B) POWER | All dimensions are in inches. They are | |

WIRING ENTRY | ||

subject to change without notice. | ||

| ||

BOTTOM SUPPLY | Certified dimensions will be provided | |

upon request. | ||

AND RETURN | ||

| ||

AIR OPENINGS |

|

(See Note)

UNIT BASE RAILS

Shown separately to illustrate | (D) |

Bottom Duct openings. Power | GAS SUPPLY |

and Gas Piping Connection | ENTRY |

location. |

NOTE: |

| |

For curb mounted units, refer to the curb hanger |

| |

| ||

dimensions of the curb for proper size of the |

| |

supply and return air duct connections. |

|

|

|

|

|

SUPPLY | |

AIR |

| (B) POWER WIRING |

| ENTRY |

(A) CONTROL WIRING | |

| ENTRY |

| |

|

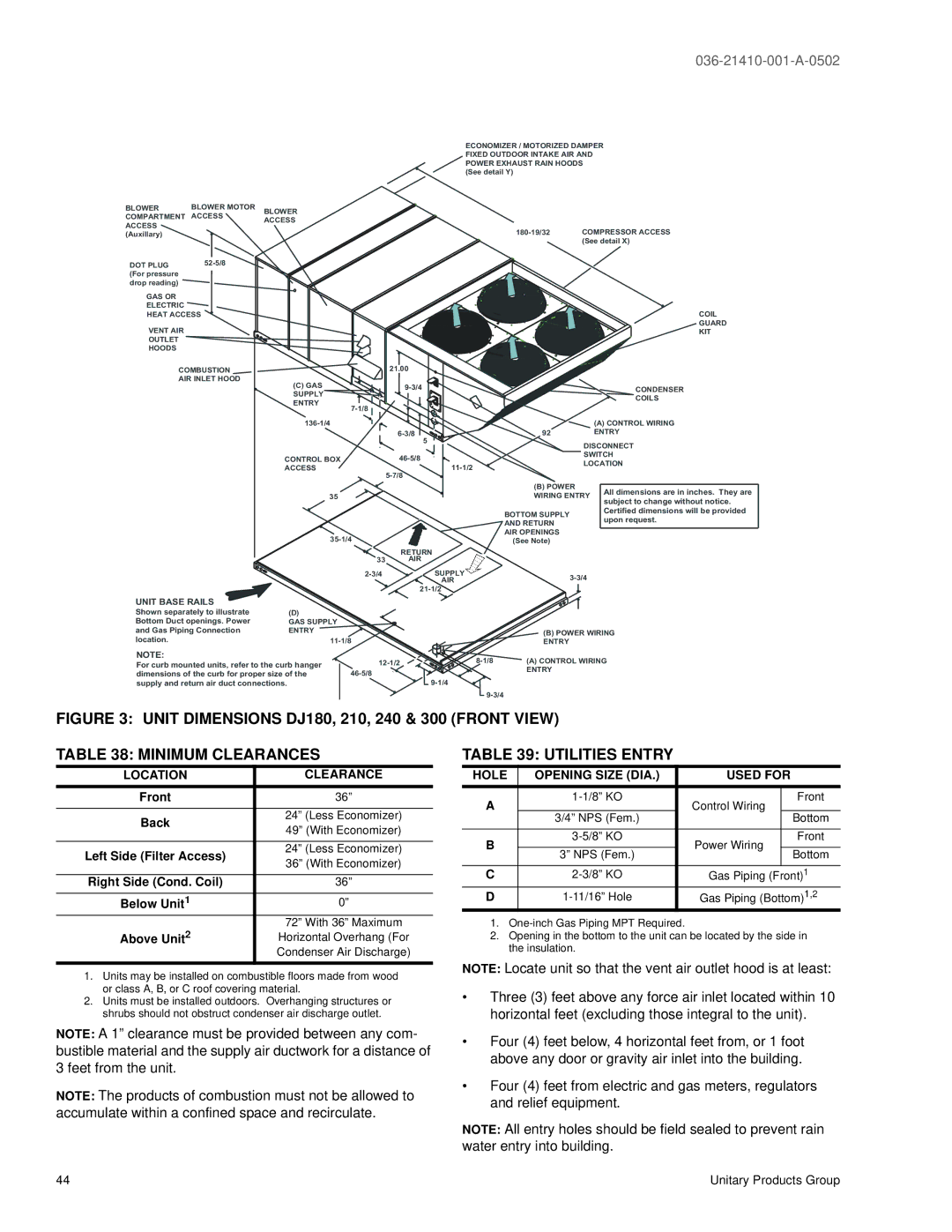

FIGURE 3: UNIT DIMENSIONS DJ180, 210, 240 & 300 (FRONT VIEW)

TABLE 38: MINIMUM CLEARANCES

LOCATION | CLEARANCE | |

|

| |

Front | 36” | |

|

| |

Back | 24” (Less Economizer) | |

49” (With Economizer) | ||

| ||

|

| |

Left Side (Filter Access) | 24” (Less Economizer) | |

36” (With Economizer) | ||

| ||

|

| |

Right Side (Cond. Coil) | 36” | |

|

| |

Below Unit1 | 0” | |

Above Unit2 | 72” With 36” Maximum | |

Horizontal Overhang (For | ||

| Condenser Air Discharge) | |

|

|

1.Units may be installed on combustible floors made from wood or class A, B, or C roof covering material.

2.Units must be installed outdoors. Overhanging structures or shrubs should not obstruct condenser air discharge outlet.

NOTE: A 1” clearance must be provided between any com- bustible material and the supply air ductwork for a distance of 3 feet from the unit.

NOTE: The products of combustion must not be allowed to accumulate within a confined space and recirculate.

TABLE 39: UTILITIES ENTRY

HOLE | OPENING SIZE (DIA.) | USED FOR | ||

|

|

|

| |

A | Control Wiring | Front | ||

|

| |||

| 3/4” NPS (Fem.) |

| Bottom | |

|

|

|

| |

B | Power Wiring | Front | ||

|

| |||

3” NPS (Fem.) | Bottom | |||

|

| |||

|

|

|

| |

C | Gas Piping (Front)1 | |||

D | Gas Piping (Bottom)1,2 | |||

1.

2.Opening in the bottom to the unit can be located by the side in the insulation.

NOTE: Locate unit so that the vent air outlet hood is at least:

•Three (3) feet above any force air inlet located within 10 horizontal feet (excluding those integral to the unit).

•Four (4) feet below, 4 horizontal feet from, or 1 foot above any door or gravity air inlet into the building.

•Four (4) feet from electric and gas meters, regulators and relief equipment.

NOTE: All entry holes should be field sealed to prevent rain water entry into building.

44 | Unitary Products Group |