W1747 20" Planer

Extension Wings

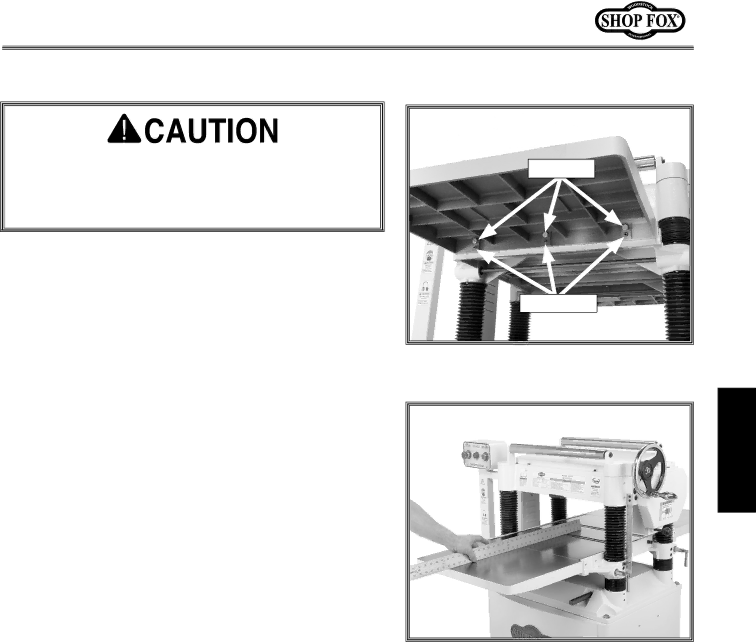

Extension wings are heavy and could cause per- sonal injury if dropped during installation. Have an assistant hold the table while you fasten it to the planer.

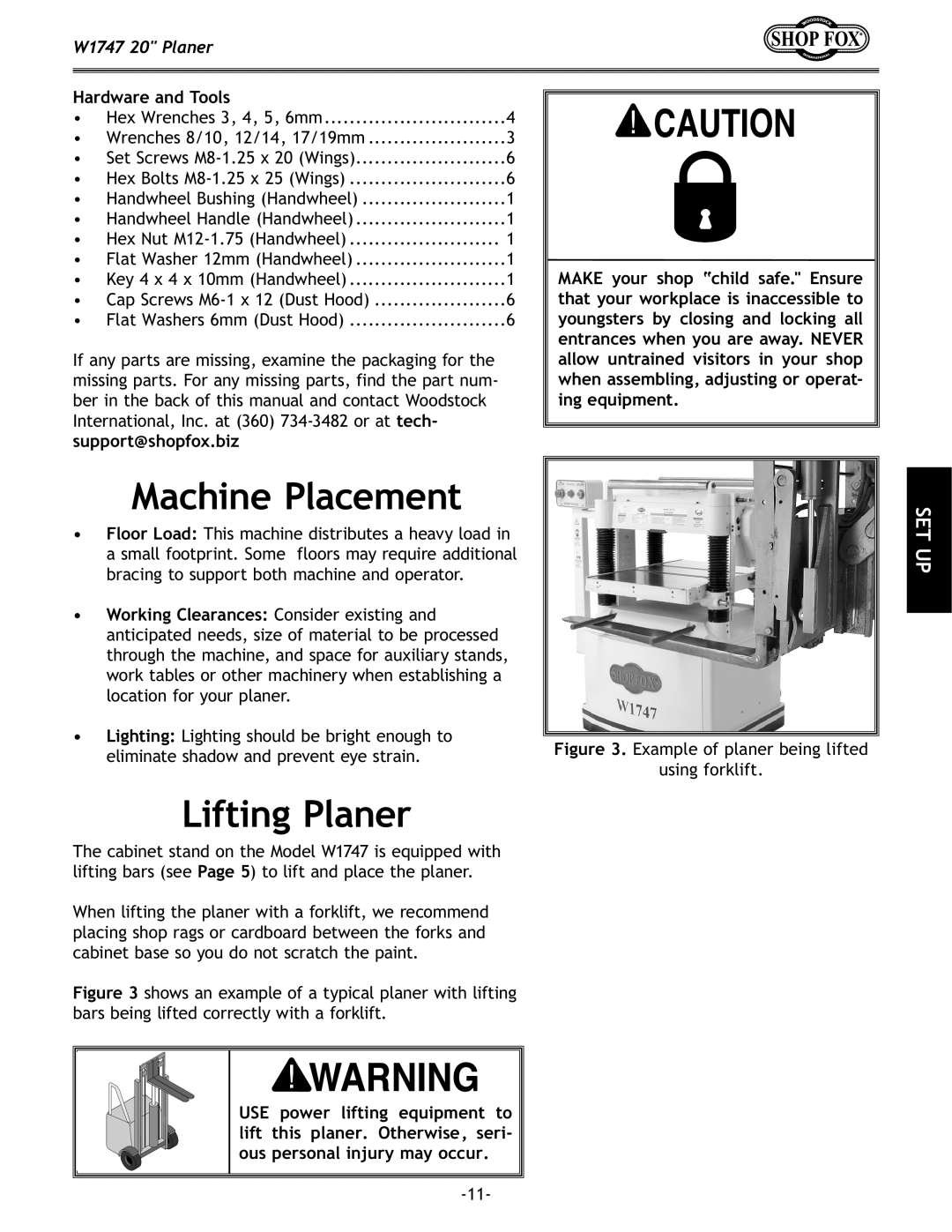

To attach the table extension wings, do these steps:

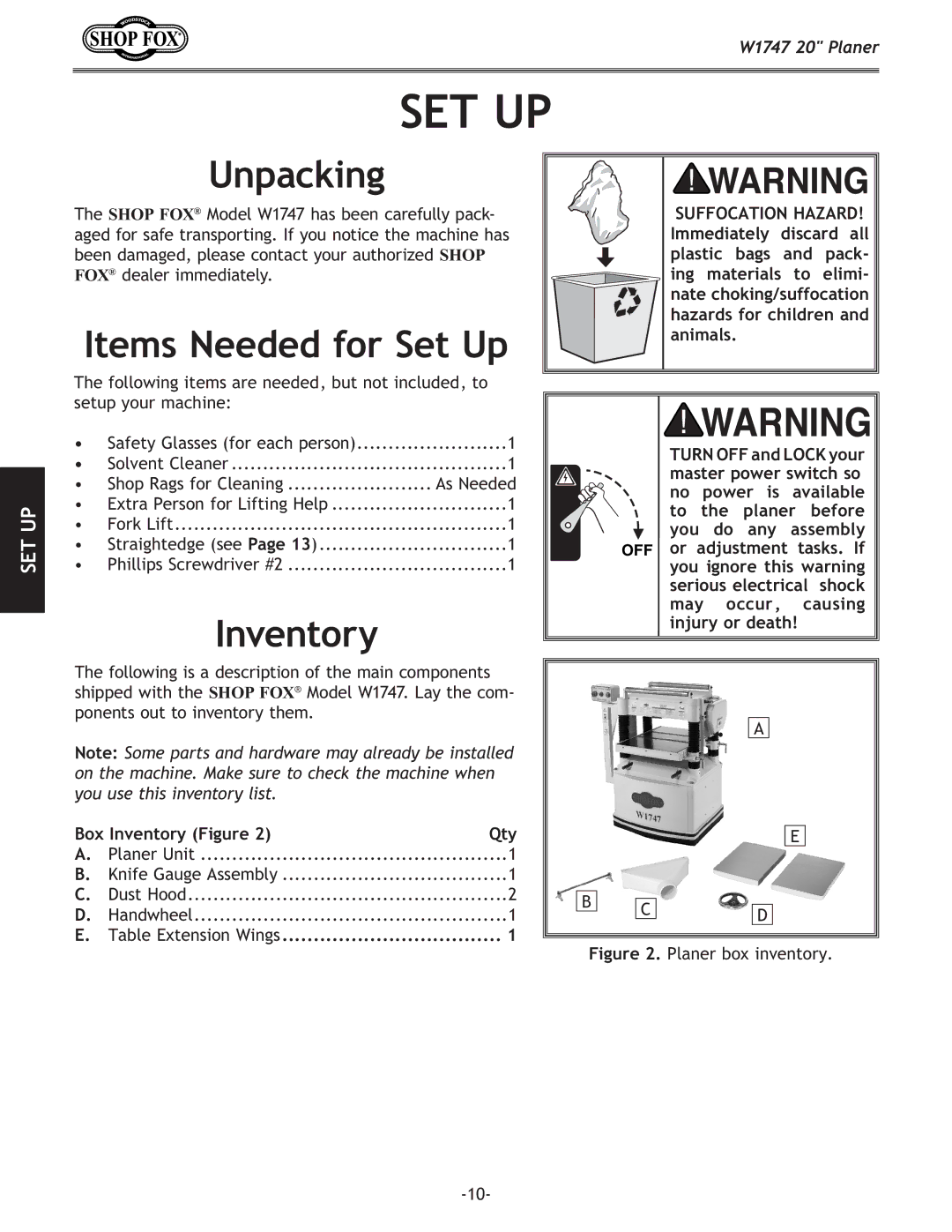

1.With the help of an assistant, attach the table extension wings to the planer table (Figure 4) with the

2.Install the

3.Check

4.Tighten the hex bolts.

Hex Bolts

Set Screws

Figure 4. Extension wing fasteners and

leveling controls.

SET UP

Figure 5. Leveling extension wings and

table.