Installation &

Removal Devices

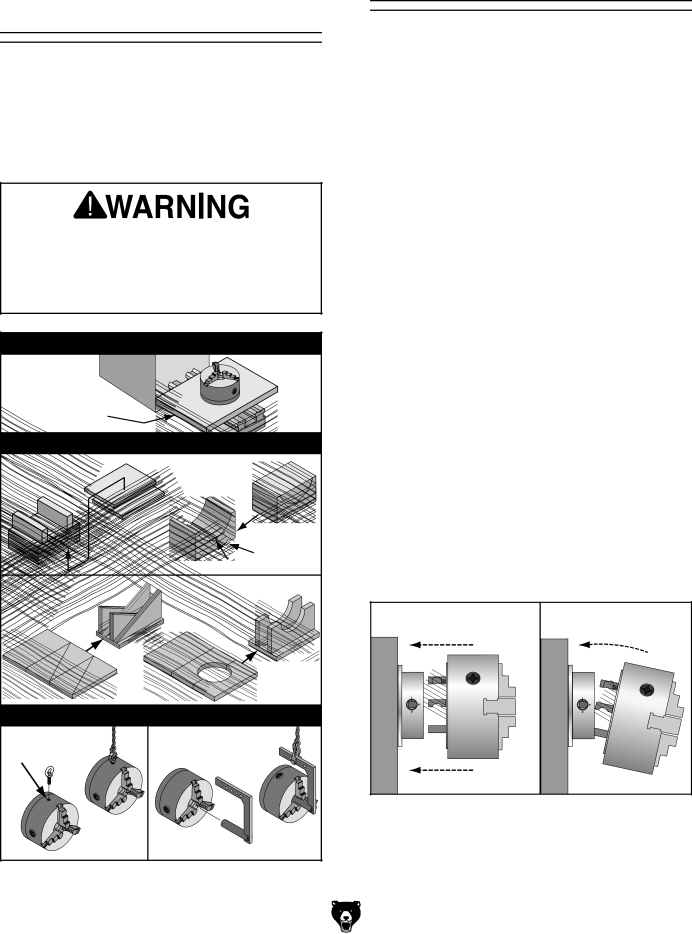

Because chucks are heavy and often awkward to hold, some kind of lifting, support, or protec- tive device should be used during installation or removal. the weight and size of the chuck will determine the appropriate device to use (refer to the following figure for examples).

Dropping a chuck can result in amputation, serious crushing injuries, or property dam- age. Always use a support or protective device to reduce this risk during installation or removal.

SMALL, LIGHTWEIGHT CHUCKS | |

Plywood Protection |

|

Plate for Chucks |

|

Installed by Hand |

|

| |

Plywood & 2x4 | Solid Block |

Chuck Cradle | Chuck Cradle |

| |

| Way Slot |

| Jaw Slot |

Plywood Chuck Cradle | Plywood Chuck Cradle |

(Straight Cuts) | (Curved Cuts) |

LARGE, VERY HEAVY CHUCKS | |

Fabricated Steel | |

for Lifting Eye | Lifting Hook |

Figure 32. Examples of common devices used

during chuck installation and removal.

Chuck Installation

to ensure accurate work, it is extremely important to make sure the spindle nose and chuck mating surfaces/tapers are clean. Even a small amount of lint or debris can affect accuracy.

the chuck is properly installed when all camlocks are tight, the spindle and chuck tapers firmly lock together, and the back of the chuck is firmly seated against the face of the spindle all the way

To install the chuck:

1.disCoNNECt lathE FroM poWEr!

2.Use an appropriate lifting, support, or protec- tive device to protect the ways and support the chuck during the installation process (refer to the installation & Removal Devices section on the previous page).

3.Clean and lightly oil the camlock studs, then thoroughly clean the mating surfaces of the spindle and chuck.

4.install the chuck by inserting the camlock studs straight into the spindle cam holes.

important: Avoid inserting the studs by piv- oting them in from an angle or rotating the spindle. This can damage studs or spindle cam holes.

CORRECT | INCORRECT |