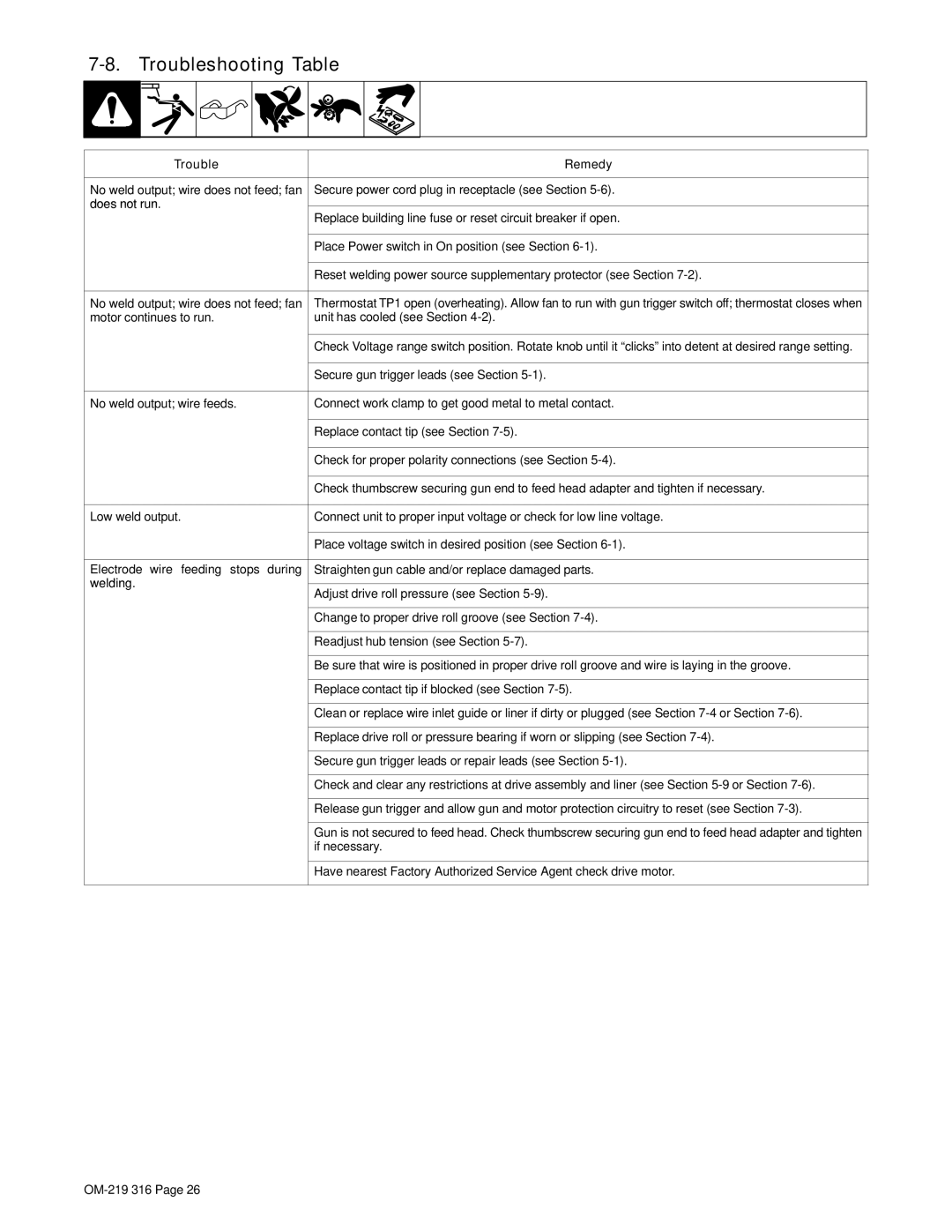

Problem | Probable Cause | Remedy |

|

|

|

Welding arc not stable. | Wire slipping in drive rolls. | Adjust pressure setting on wire feed rolls. Replace worn |

|

| drive rolls if necessary. |

|

|

|

| Wrong size gun liner or contact tip. | Match liner and contact tip to wire size and type. |

|

|

|

| Incorrect voltage setting for selected wire feed speed on | Readjust welding parameters. |

| welding power source. |

|

|

|

|

| Loose connections at the gun weld cable or work cable. | Check and tighten all connections. |

|

|

|

| Gun in poor shape or loose connection inside gun. | Repair or replace gun as necessary. |

|

|

|