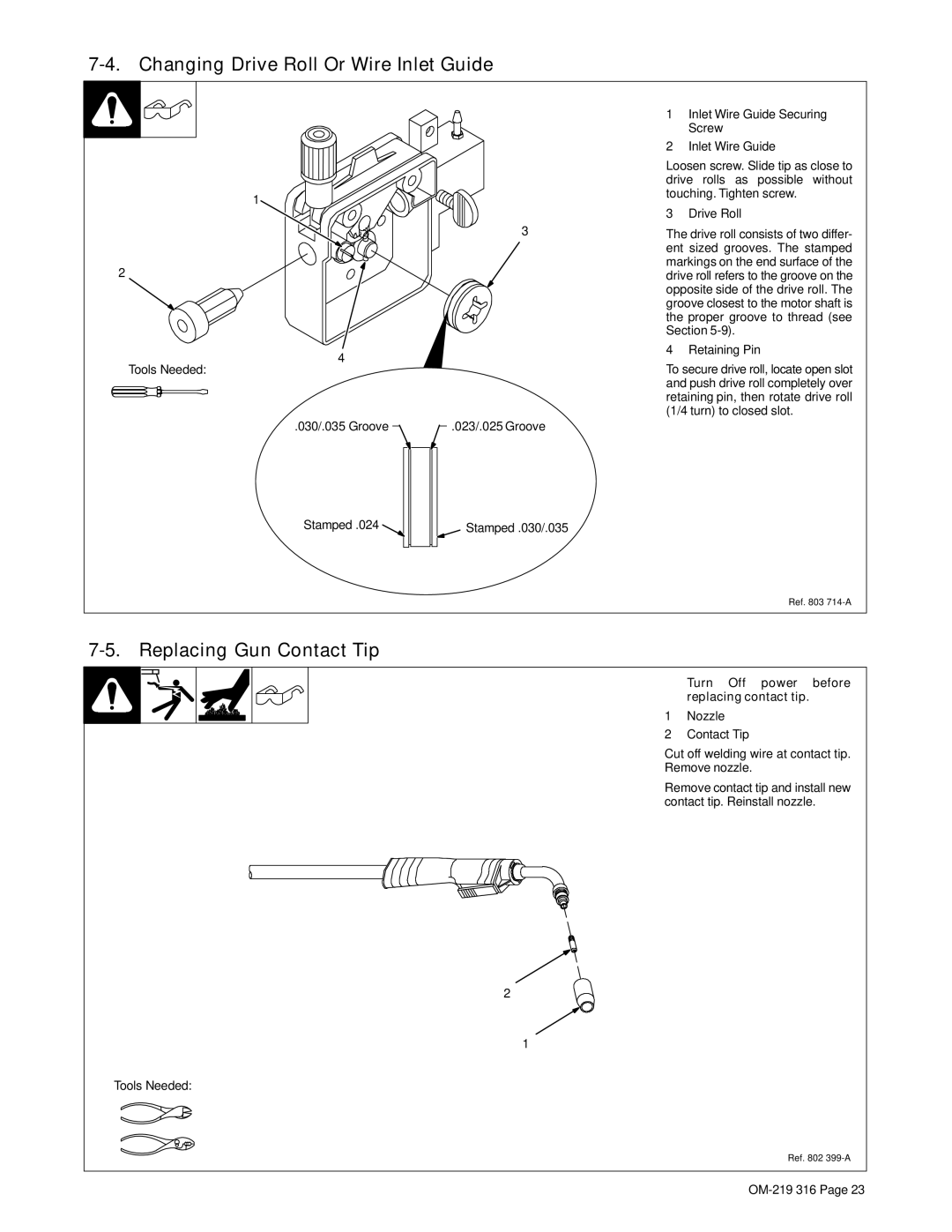

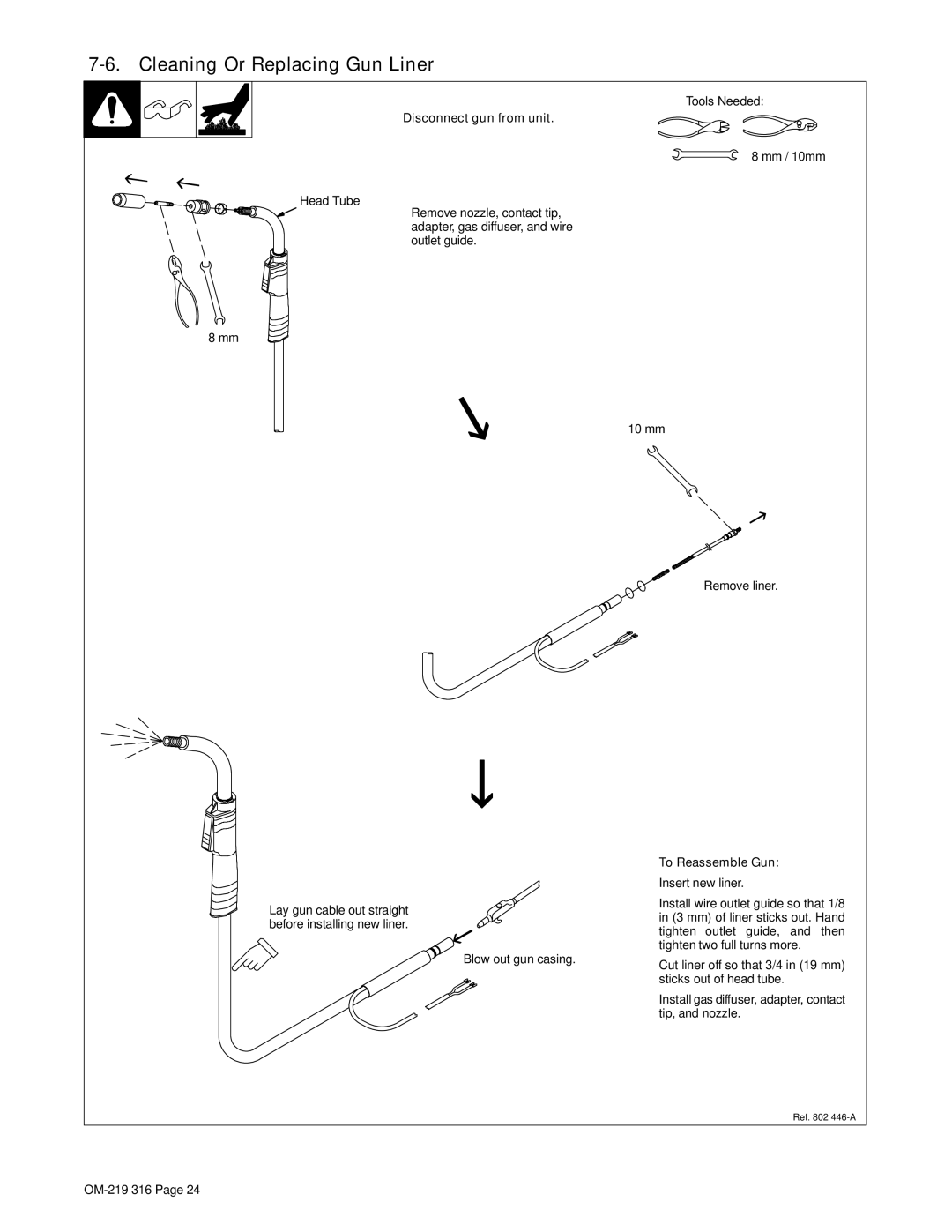

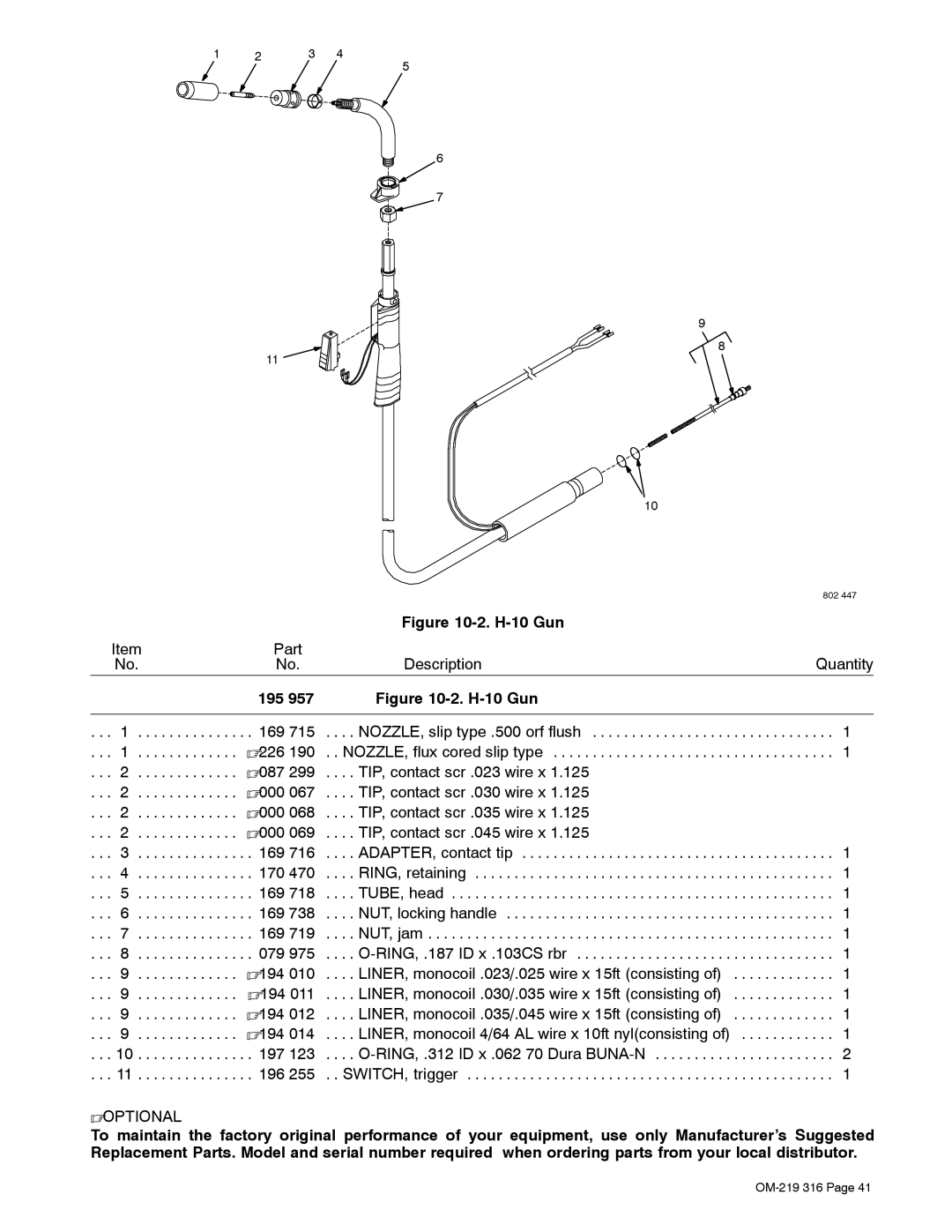

7-6. Cleaning Or Replacing Gun Liner

Tools Needed:

Y Disconnect gun from unit.

Head Tube

8 mm

8 mm / 10mm

Remove nozzle, contact tip, adapter, gas diffuser, and wire outlet guide.

10 mm

Remove liner.

Lay gun cable out straight before installing new liner.

To Reassemble Gun:

Insert new liner.

Install wire outlet guide so that 1/8 in (3 mm) of liner sticks out. Hand tighten outlet guide, and then tighten two full turns more.

Blow out gun casing. | Cut liner off so that 3/4 in (19 mm) |

| |

| sticks out of head tube. |

Install gas diffuser, adapter, contact tip, and nozzle.

Ref. 802