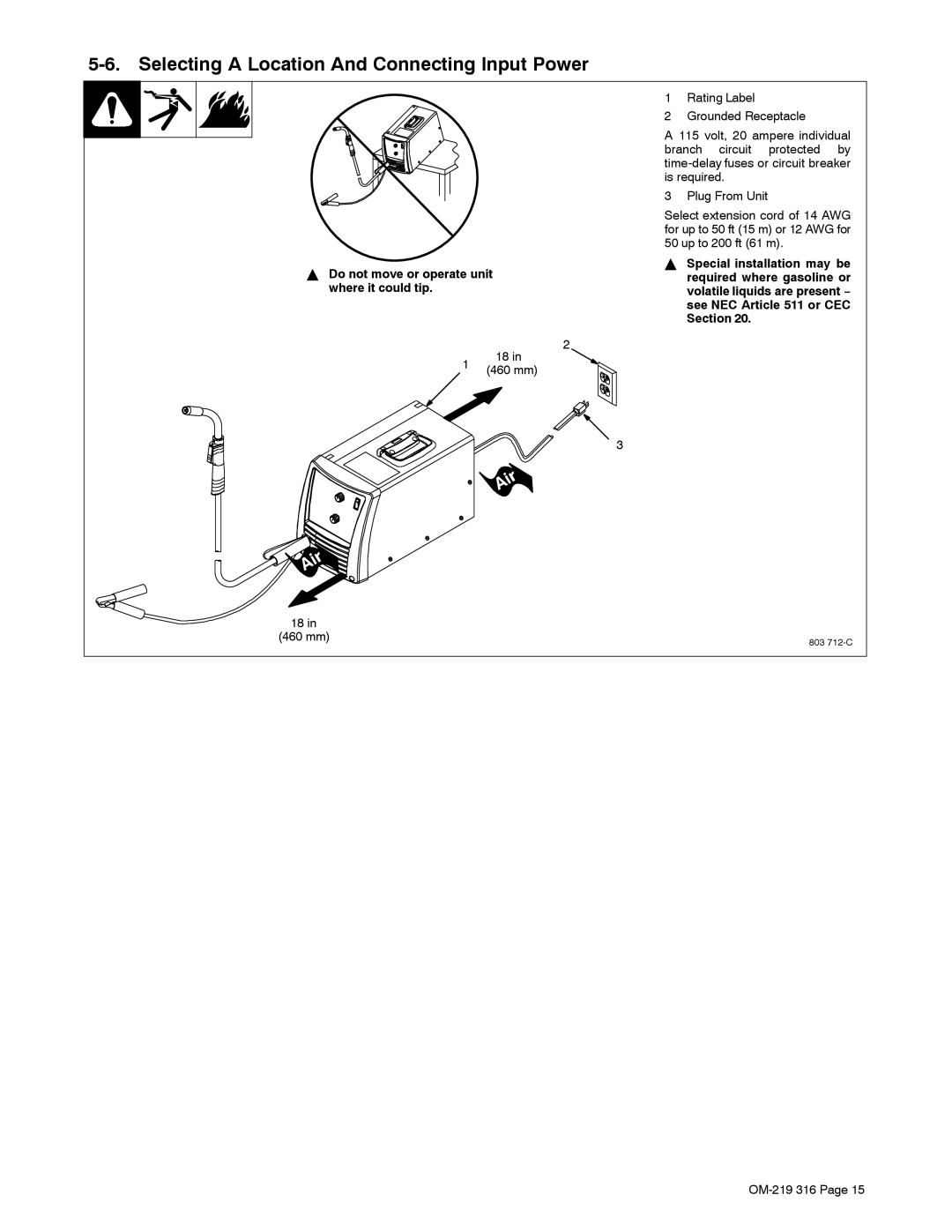

5-6. Selecting A Location And Connecting Input Power

YDo not move or operate unit where it could tip.

| 2 | |

1 | 18 in | |

(460 mm) | ||

|

3

1Rating Label

2Grounded Receptacle

A 115 volt, 20 ampere individual branch circuit protected by

3 Plug From Unit

Select extension cord of 14 AWG for up to 50 ft (15 m) or 12 AWG for 50 up to 200 ft (61 m).

YSpecial installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20.

18 in |

|

(460 mm) | 803 |

|