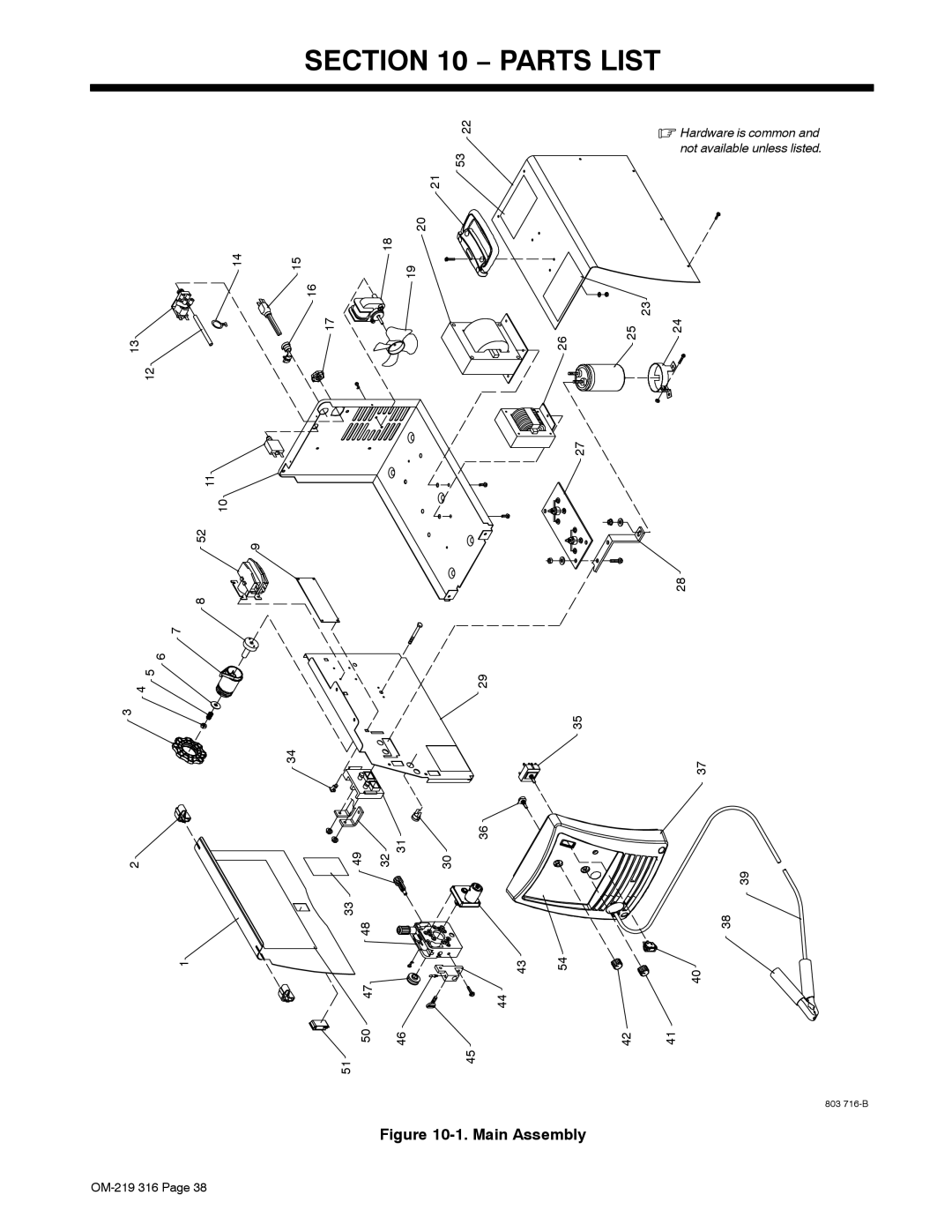

Item | Dia. | Part | Description | Quantity |

No. | Mkgs. | No. | ||

|

|

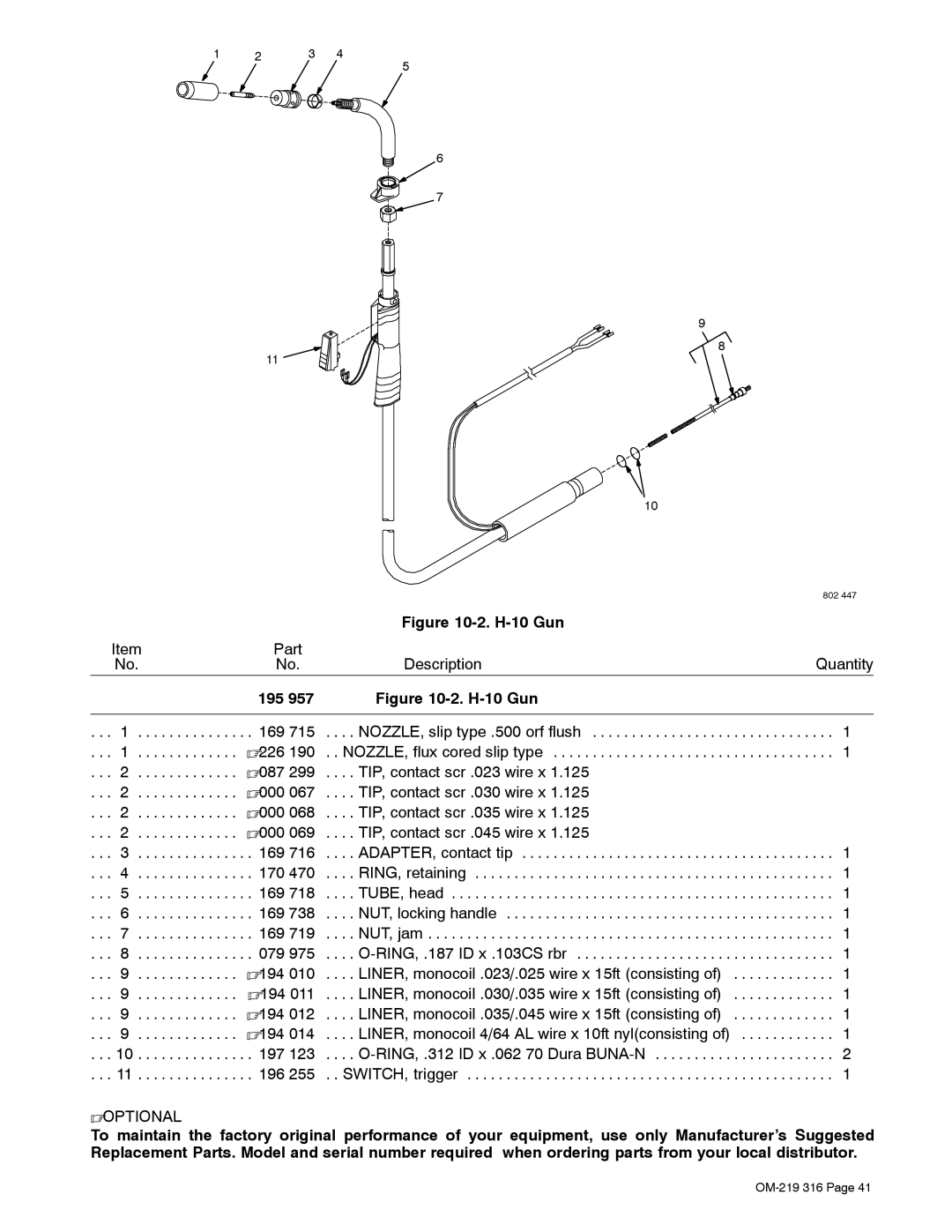

| Figure |

|

|

|

|

|

|

. . . 41 | . . . . . . . . . | 207 079 | . . KNOB, pointer (voltage) | . . . 1 |

. . . 42 | . . . . . . . . . | 211 338 | . . KNOB, pointer (WFS) | . . . 1 |

. . . 43 | . . . . . . . . . | 217 778 | . . MOTOR, gear | . . . 1 |

. . . 44 | . . . . . . . . . | 193 189 | . . CONNECTOR, gun | . . . 1 |

. . . 45 | . . . . . . . . . | 196 654 | . . SCREW, thumb | . . . 1 |

. . . 46 | . . . . . . . . . | 230 012 | . . FITTING, gas barbed | . . . 1 |

. . . 47 | . . . . . . . . . | 202 925 | . . ROLL, feed .024 in, .030/.035 in | . . . 1 |

. . . 48 | . . . . . . . . . | 194 508 | . . HEAD, feed assy | . . . 1 |

. . . 49 | . . . . . . . . . | 203 025 | . . GUIDE, wire inlet | . . . 1 |

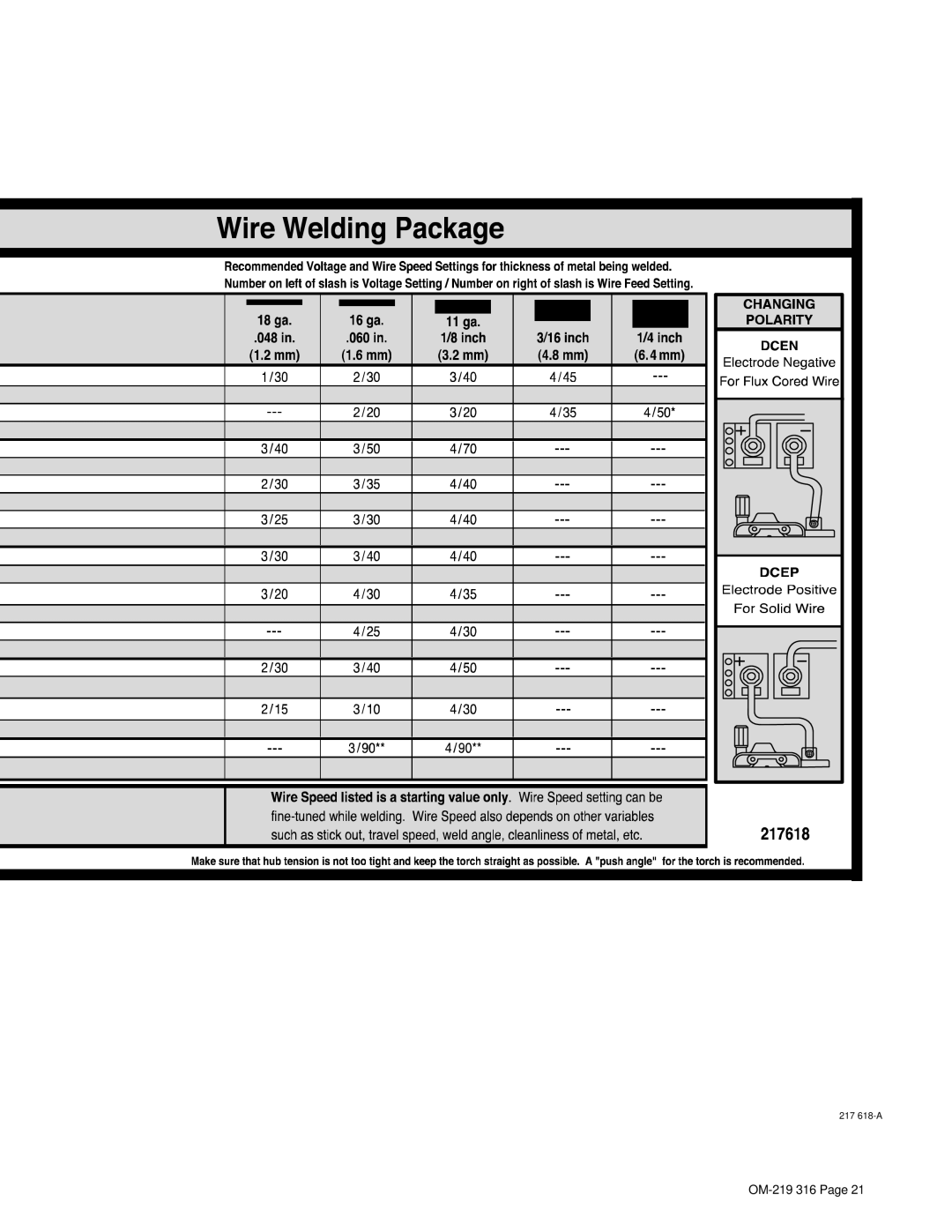

. . . 50 | . . . . . . . . . | 217 618 | . . LABEL, weld chart | . . . 1 |

. . . 50 | . . . . . . . . . | 221 079 | . . LABEL, weld chart (French) | . . . 1 |

. . . 51 | . . . . . . . . . | 204 711 | . . LATCH | . . . 1 |

. . . 52 | . . . . . . . . . | 217 584 | . . CONTACTOR | . . . 1 |

. . . 53 | . . . . . . . . . | 203 572 | . . LABEL, warn gen precaution (EN/FR models only) | . . . 1 |

. . . 54 | . . . . . . . . . | . . . . . . . . . | . . LABEL, nameplate (order by model and serial number) | . . . 1 |

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

To maintain the factory original performance of your equipment, use only Manufacturer’s Suggested Replacement Parts. Model and serial number required when ordering parts from your local distributor.