|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

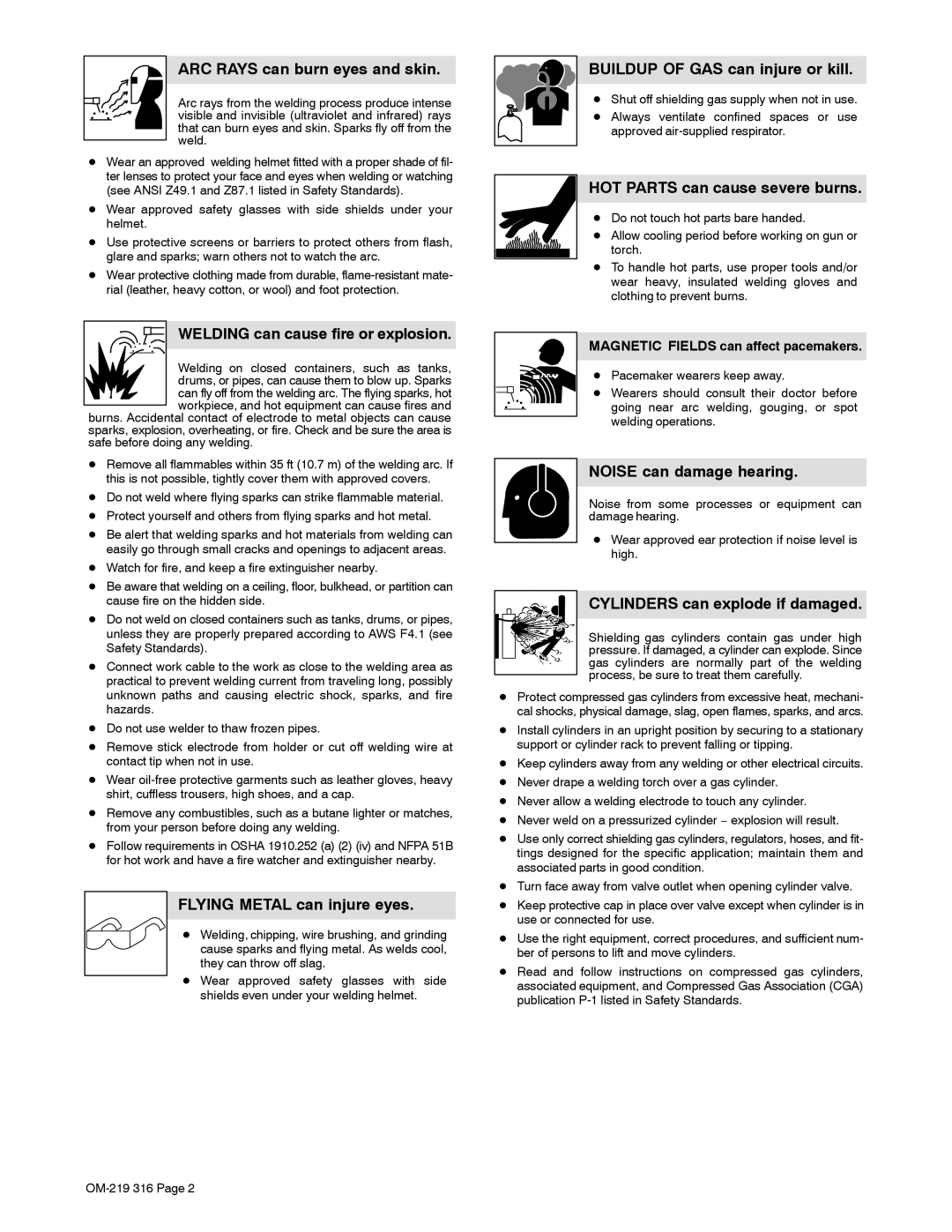

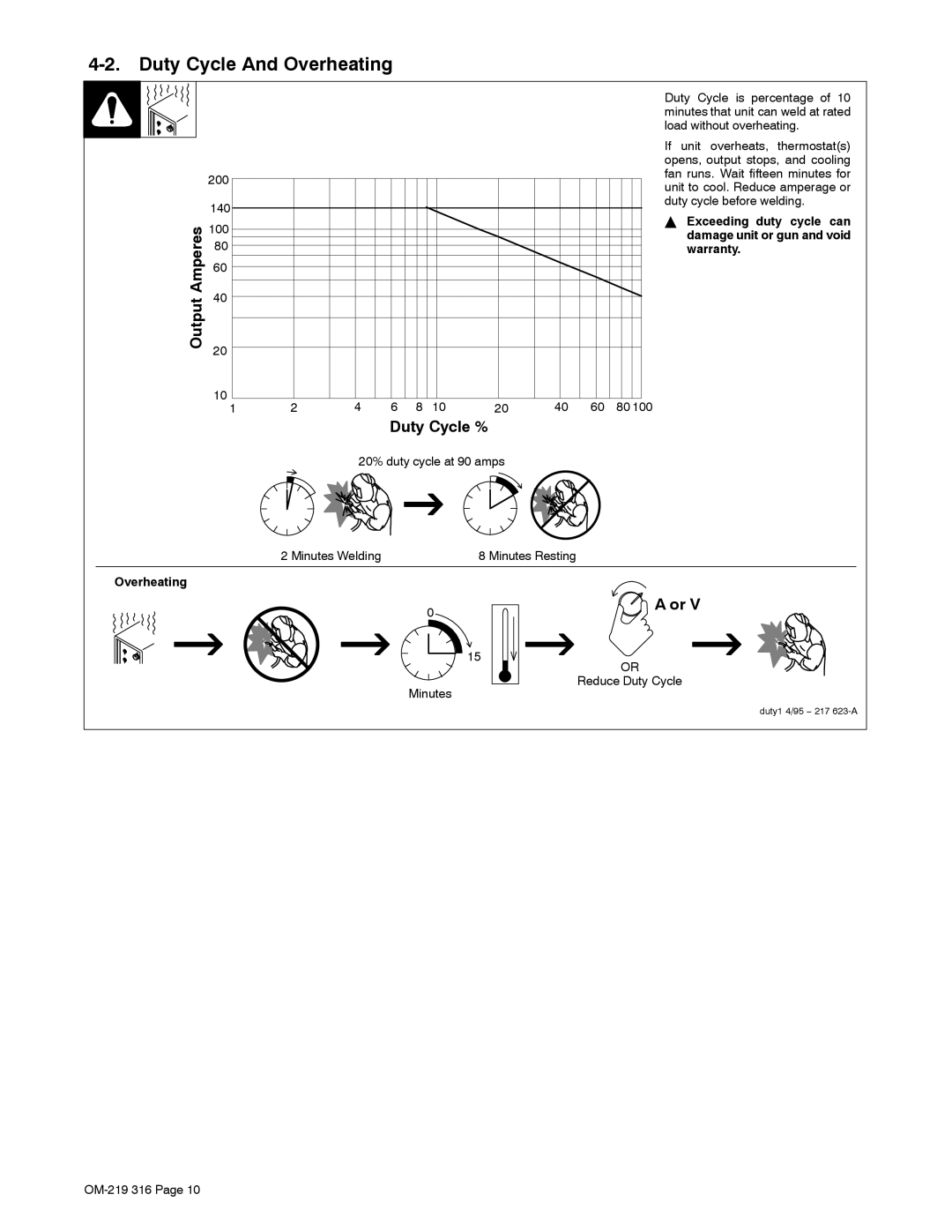

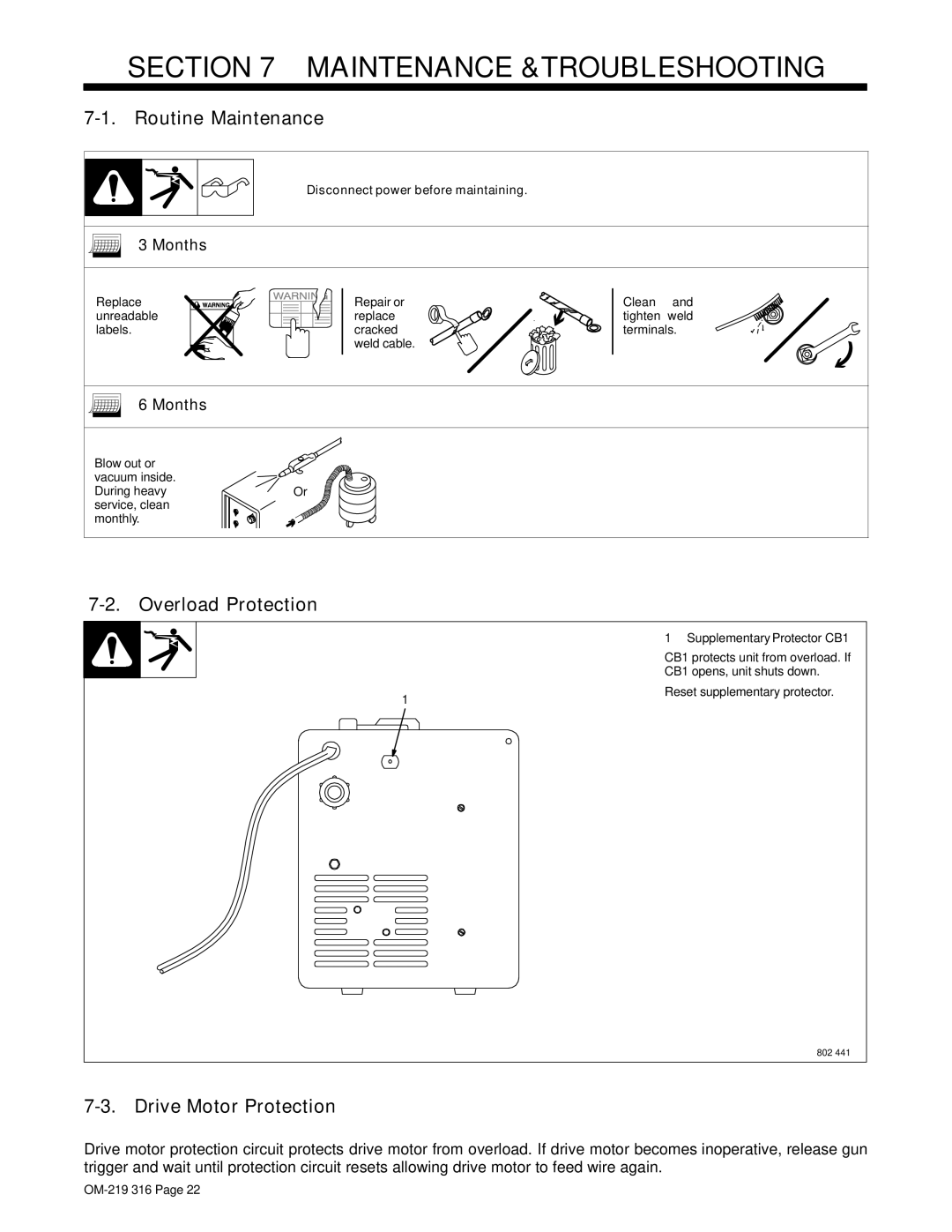

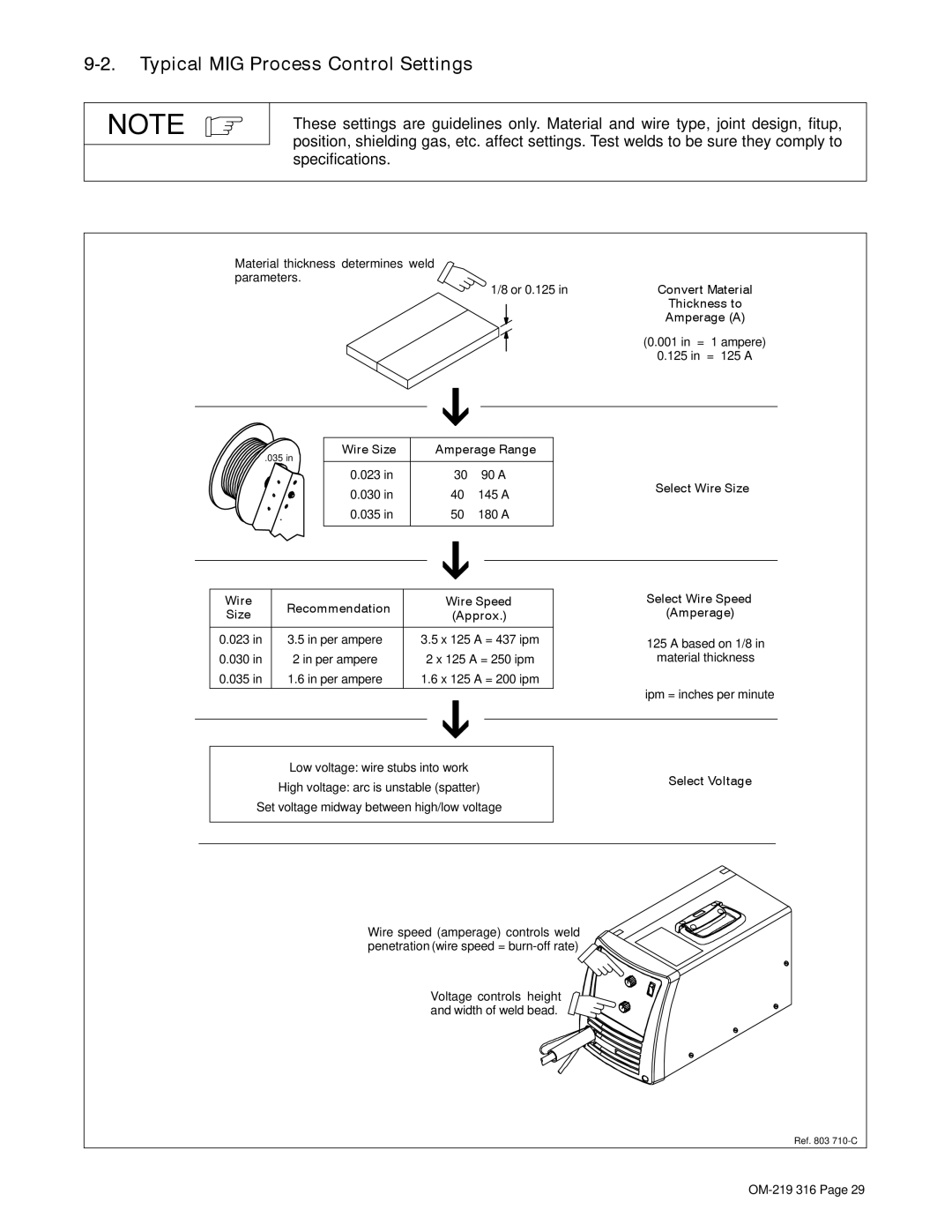

| Duty Cycle is percentage of 10 |

|

|

|

|

|

|

|

|

|

| minutes that unit can weld at rated |

|

|

|

|

|

|

|

|

|

| load without overheating. |

|

|

|

|

|

|

|

|

|

| If unit overheats, thermostat(s) |

|

|

|

|

|

|

|

|

|

| opens, output stops, and cooling |

| 200 |

|

|

|

|

|

|

|

| fan runs. Wait fifteen minutes for |

|

|

|

|

|

|

|

|

| unit to cool. Reduce amperage or | |

|

|

|

|

|

|

|

|

|

| |

| 140 |

|

|

|

|

|

|

|

| duty cycle before welding. |

|

|

|

|

|

|

|

|

| Y Exceeding duty cycle can | |

Amperes | 100 |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| damage unit or gun and void | ||

80 |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| warranty. | |

| 60 |

|

|

|

|

|

|

|

|

|

Output | 40 |

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

| 10 | 2 | 4 | 6 | 8 | 10 |

| 40 | 60 | 80 100 |

| 1 | 20 | ||||||||

|

|

|

| Duty Cycle % |

|

|

| |||

|

|

| 20% duty cycle at 90 amps |

|

|

| ||||

|

| 2 Minutes Welding |

|

|

| 8 Minutes Resting |

|

| ||

Overheating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0 |

|

|

| A or V |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| 15 |

|

| OR |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| Minutes |

|

| Reduce Duty Cycle | ||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| duty1 4/95 − 217 |