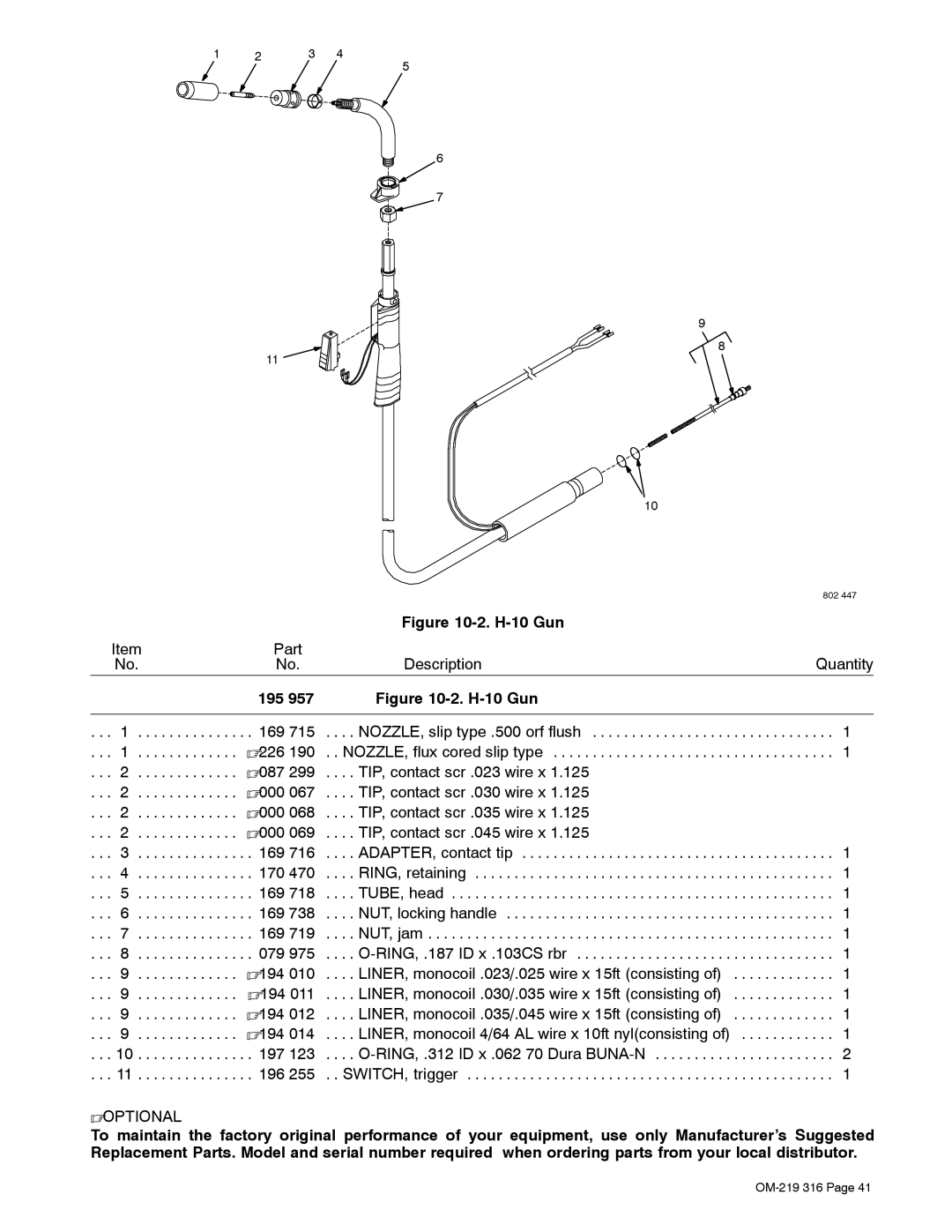

1 | 2 | 3 | 4 |

|

|

| 5 |

6

7

9

8

11

10

|

|

|

| 802 447 |

|

|

| Figure |

|

| Item | Part | Description | Quantity |

| No. | No. | ||

|

| 195 957 | Figure |

|

|

|

|

|

|

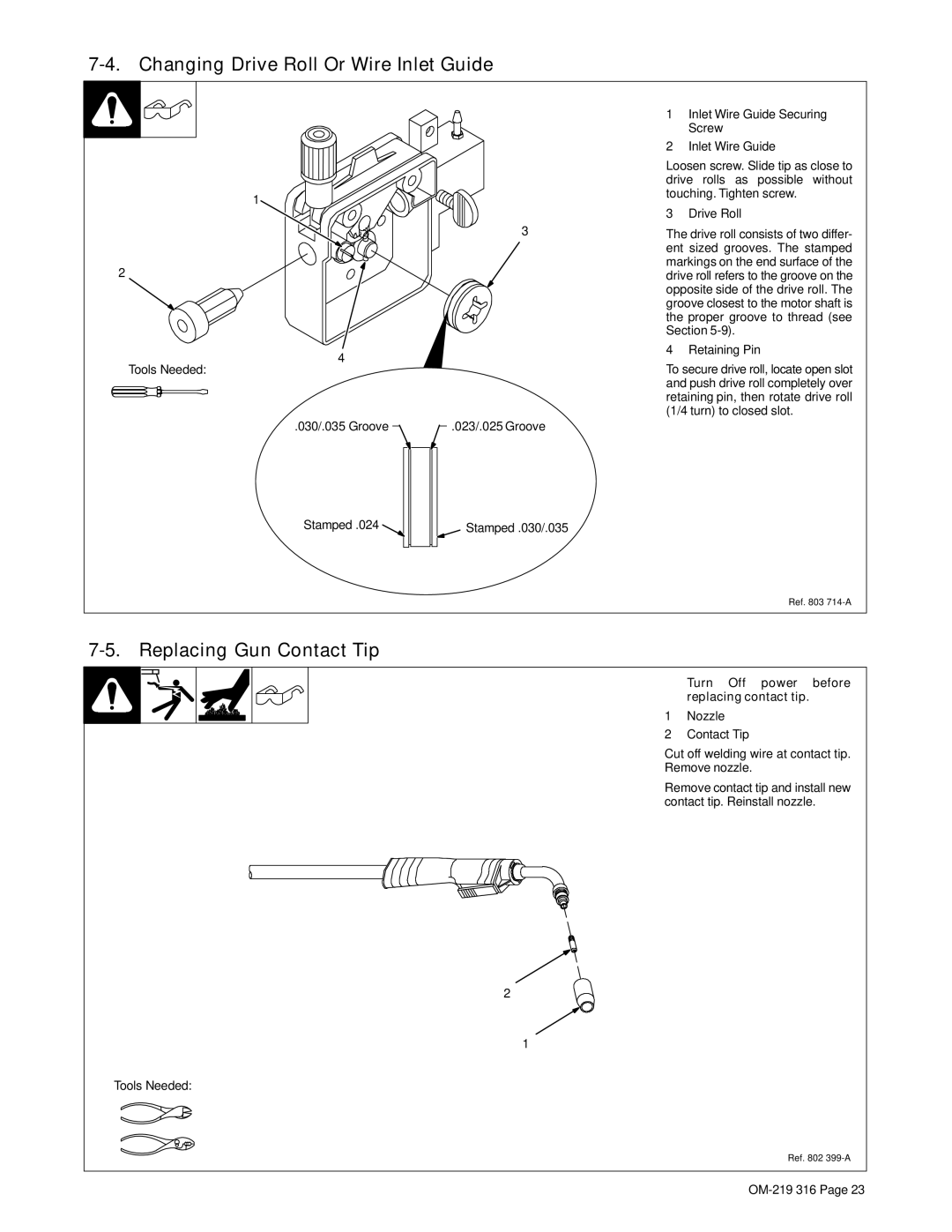

. . . | 1 | . 169 715 | . . . . NOZZLE, slip type .500 orf flush | . . . 1 |

. . . | 1 | ♦226 190 | . . NOZZLE, flux cored slip type | . . . 1 |

. . . | 2 | ♦087 299 | . . . . TIP, contact scr .023 wire x 1.125 |

|

. . . | 2 | ♦000 067 | . . . . TIP, contact scr .030 wire x 1.125 |

|

. . . | 2 | ♦000 068 | . . . . TIP, contact scr .035 wire x 1.125 |

|

. . . | 2 | ♦000 069 | . . . . TIP, contact scr .045 wire x 1.125 |

|

. . . | 3 | . 169 716 | . . . . ADAPTER, contact tip | . . . 1 |

. . . | 4 | . 170 470 | . . . . RING, retaining | . . . 1 |

. . . | 5 | . 169 718 | . . . . TUBE, head | . . . 1 |

. . . | 6 | . 169 738 | . . . . NUT, locking handle | . . . 1 |

. . . | 7 | . 169 719 | . . . . NUT, jam | . . . 1 |

. . . | 8 | . 079 975 | . . . . | . . . 1 |

. . . | 9 | ♦194 010 | . . . . LINER, monocoil .023/.025 wire x 15ft (consisting of) | . . . 1 |

. . . | 9 | ♦194 011 | . . . . LINER, monocoil .030/.035 wire x 15ft (consisting of) | . . . 1 |

. . . | 9 | ♦194 012 | . . . . LINER, monocoil .035/.045 wire x 15ft (consisting of) | . . . 1 |

. . . | 9 | ♦194 014 | . . . . LINER, monocoil 4/64 AL wire x 10ft nyl(consisting of) | . . . 1 |

. . . 10 | . 197 123 | . . . . | . . . 2 | |

. . . 11 | . 196 255 | . . SWITCH, trigger | . . . 1 | |

♦OPTIONAL

To maintain the factory original performance of your equipment, use only Manufacturer’s Suggested Replacement Parts. Model and serial number required when ordering parts from your local distributor.