Maintenance | Section 4 |

|

|

Water Inlet Valve

The water inlet valve normally does not require removal for cleaning. Refer to Section 5 for a list of causes for “No Water Entering Water Trough” or “Water Overflows Water Trough.

1.When the ice machine is off, the water inlet valve must completely stop water flow into the machine.

2.When the ice machine is on, the water inlet valve must allow the proper water flow through it. Set the toggle switch to ON. Watch for water flow into the ice machine. If the water flow is slow or only trickles into the ice machine, refer to Section 5.

Follow the procedure below to remove the water inlet valve.

!Warning

Disconnect the electric power to the ice machine and dispenser at the electric service switch box and turn off the water supply before proceeding.

1.Remove the 1/4” hex head screws.

2.Remove, clean, and install the filter screen.

FILTER

ACCESS

SCREWS

WATER

![]() INLET

INLET

VALVE

SV1622

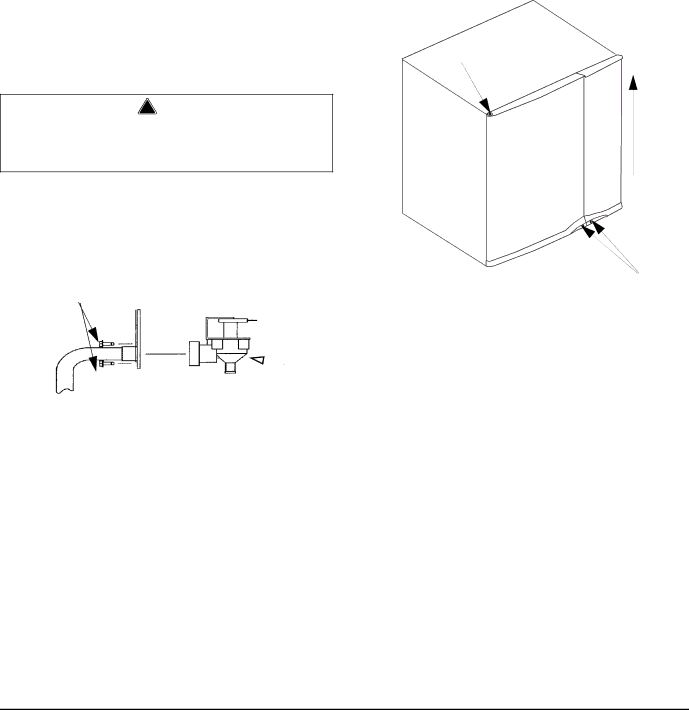

Removing the Front Panels

NOTE: The front panels do not normally have to be removed. If needed perform the following procedure.

1.Loosen screws. Do not remove they are retained by

2.30 Inch and 48 Inch Models Only: To remove right front door lift up and remove (22 inch machines have a single door, proceed to step 3).

5

3

2

Door Removal

3.Open left front door to 45 degrees.

4.Support with left hand, depress top pin, tilt top of door forward and lift out of bottom pin to remove.

Part Number |