3M Industrial Adhesives and Tapes

3M 2011 44-0009-2077-5 B070811-NA

Page

Industrial Adhesives and Tapes

This page is Blank

Safety

Introduction

General Information

This page is Blank

Table of Contents Shipment, Handling, and Storage

Installation

Safety devices

Unpacking

This page is Blank

Taping Head Information

Abbreviations and Acronyms List of ABBREVIATIONS, Acronyms

Manufacturing Specifications / Description / Intended Use

Introduction

3M-MaticTM700r Random Case Sealer, Type

Manual Maintenance

Importance of the Manual

Consulting the Manual

General Information

Data Identifying Manufacturer and Machine

Contents-700r Random Case Sealer

Safety

General Safety Information

Explanation of Signal Word and Possible Consequences

To reduce the risk associated with hazardous voltage

To reduce the risk associated with sharp blade hazards

To reduce the risk associated with muscle strain

To reduce the risk associated with pinch hazards

Personal Safety Measures

Operators Qualifications

Number of Operators

Residual Hazards

Skill 2 Mechanical Maintenance Technician

Skill 2a Electrical Maintenance Technician

Skill 1 Machine Operator

Assembly Roll Mount

Component Locations

10 Replacement Labels/3M Part Numbers 78-8070-1329-3

11 Replacement Labels/3M Part Numbers

12 Replacement Labels/3M Part Numbers

Specifications

Specifications Tape Roll Diameter

Box Weight and Size Capacities

Tape Application Leg Length Standard

Tape Application Leg Length Optional

Setup Recommendations

Machine Noise Level

SHIPMENT-HANDLING-STORAGE, Transport

Packaging for Overseas Shipment Optional Figure

Handling and Transportation of Uncrated Machine

Storage of the Packed or Unpacked Machine

Unpacking

Uncrating

Removal of Pallet

Installation

M8 x 1.25mm Socket Head Screws Adjustable Legs

Machine Positioning / Bed Height

Tool Kit Supplied with the Machine

Installation Removal of Plastic Ties

Assembly Completion / Machine Setup

Position Figure

Installation Machine Setup

See -7B

To reduce the risk associated with impact hazards

Installation and Setup Column Guards

700r Frame Setup

Installation and Setup Infeed Conveyor Assembly

Centering Guides

Outboard Tape Roll Mounting

Tape Leg Length

Box Size Capacity of Case Sealer

Electrical Connections and Controls

Initial Start-Up of Case Sealer

13 700r Case Sealer Components Left Front View

Adjust

Air Supply Filter Connector

Up to

Down

Centering Switch, Box Centering Guide

16- Air Regulator, Centering Guides Locking Nut

Installation and Setup

Mechanical Latch, Upper Drive Assembly

Main Air Pressure Gauge

Theory of Operation Box Centering Switch

Raising Switch

Tape Loading/Threading

To reduce the risk associated with pinch and impact hazards

Installation and Setup Tape Loading and Threading

Box Sealing

Installation Completion of Taping Heads

Inspection of Phases For Three-Main Phases Only

Outboard Tape Roll Holder

Preliminary Electric Inspection

Theory of Operation

Regulator Air Supply Filter Connector

Controls

700r-NA July

700r-NA July

Safety Devices of the Machine

Blade Guards

Emergency Stop Button

Electric System / Circuit Breaker

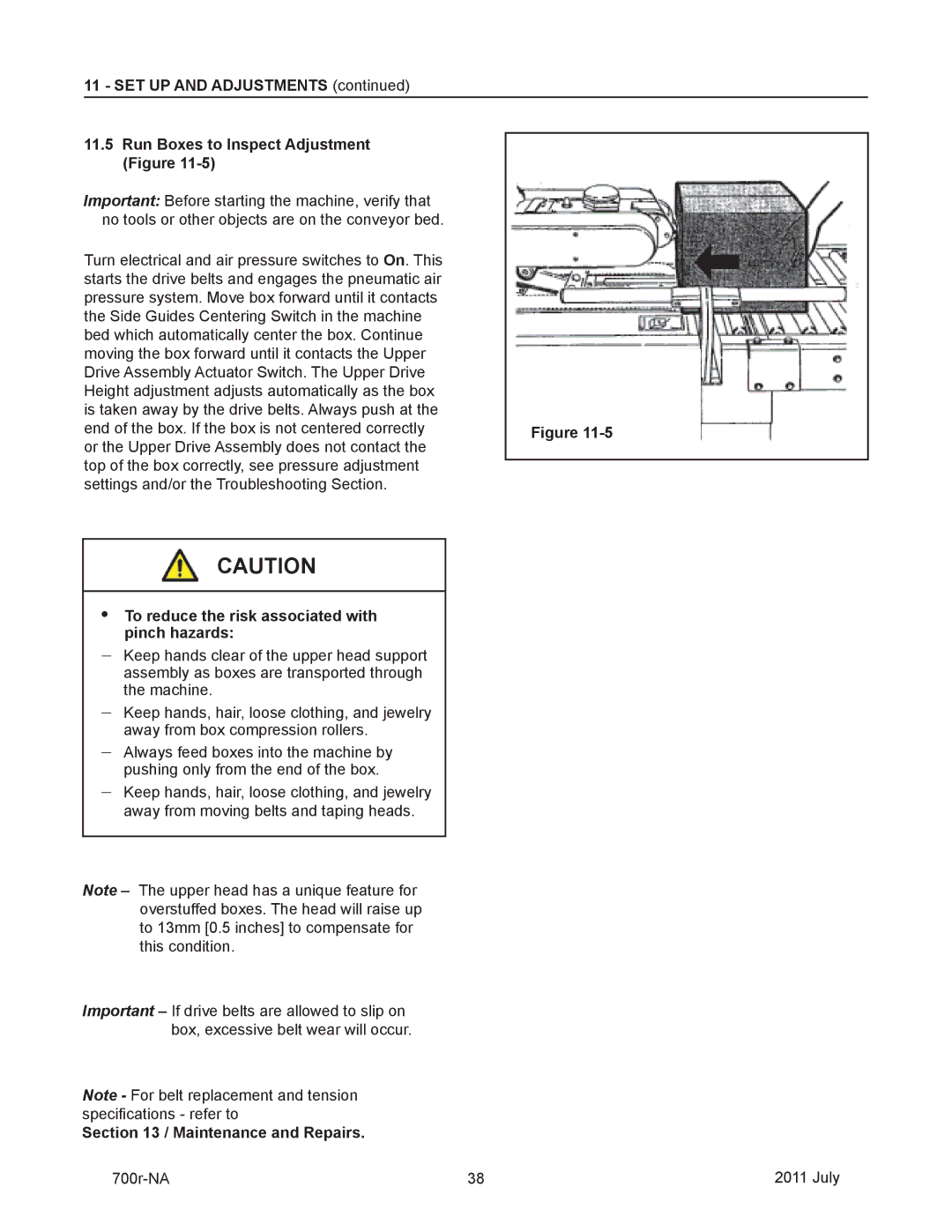

SET UP and Adjustments

Maintenance and Repairs

Operation

Troubleshooting

Troubleshooting Guide Problem Cause Correction

Page

Maintenance and Repairs

Box Drive Belt Replacement Lower Drive Belts

Upper Drive Belts

Maintenance and Repairs Drive Pulley Rings

Box Drive Belt Tension

Box Drive Belt Tension Adjustment, Lower Belts Infeed End

Page

Special Setup Procedure Column Bumper Installation

Installation Instructions Column Bumper

Shown is after Safety Guard is Removed

Safety Guard Set Screws Washers

Box and Machine Bed Height Range Refer to Figure

Box Height Range Refer to -11 / .4 / and Specif cations

This page is Blank

700r-NA July

This page is Blank

Emergency Procedures

List of Safety Features

Additional Instructions Enclosures / Special Info

Emission of Hazardous Substances

Technical Diagrams

Electric Diagram

Page

This page is Blank

Machine Model Serial Number

Labels

This page is Blank

Options and Accessories

Part Number Option/Accessory

This page is Blank

700r Random Case Sealer Frame Assemblies 700r-NA July

15 21

700r Ref. No 3M Part No Description

Caster

Option

Optional

Caster Option

CB a

700r Ref. No 3M Part No Description

18a 18b

700r Ref. No 3M Part No Description

700r 700r Random Case Sealer

700r Ref. No 3M Part No Description

71 R/H 72 L/H

700r Ref. No 3M Part No Description

16 =

700r Ref. No 3M Part No Description

68 R/H 69 L/H

700r Ref. No 3M Part No Description

700r Random Case Sealer

700r Ref. No 3M Part No Description

700r 700r Random Case Sealer

700r Ref. No 3M Part No Description

700r Random Case Sealer

700r Ref. No 3M Part No Description

13 1415

700r Ref. No 3M Part No Description

This page is Blank

3M-Matic Accuglide Upper Lower High Speed Taping Heads Inch

3M 2012 44-0009-2070-0 E010712-NA

Page

3M-Matic, AccuGlide and Scotch

This page is Blank

3M-Matic , AccuGlide and Scotch

This page is Blank

Yellow

Page

Intended Use

AccuGlide 3 Upper Taping Head 2 inch, Type

This page is Blank

General Information How to use this Manual

Updating the Manual

Them Before Installing or Operating this Equipment

To reduce the risk associated with mechanical hazards

Important Safeguards

Replacement Labels/3M Part Numbers

Specifications Tape

Taping Head Dimensions

Box Size Capacities

Dimensional Drawing

Installation Guidelines

Tape Width Adjustment

Receiving And Handling

To reduce risk associated with muscle strain

Page

Tape Loading Upper Taping Head

Tape Loading Lower Taping Head

One-Way Tension Roller Wrap Knurled Applying

AccuGlide 3 2 NA January

Blade Guard

To reduce the risk associated with

Sharp blade hazards Blade Oiler Pad

Sharp blade hazards

Applying/Buffing Roller Replacement

Hex Socket Section View 5mm HexRoller/Shaft Key Wrench

Tape Latch Alignment Figure

Tape Drum Friction Brake Figure

Applying Mechanism Spring

One-Way Tension Roller

Leading Tape Leg Length Adjustment Figure

Leading Tape Leg Length One-Way Position a

Page

Page

Spare Parts/Service Information Recommended Spare Parts

Replacement Parts and Service

Qty Part Number Description

Page

AccuGlide 3 Tape Head AccuGlide 3 2 inch

Haute Bas AccuGlide January

AccuGlide 3

Upper Head AccuGlide 3 2 NA January

Upper Head Ref. No 3M Part No Description

Upper and Lower Heads

Upper and Lower Heads Ref. No 3M Part No Description

Upper Head

Upper Head Ref. No 3M Part No Description

Upper and Lower Heads AccuGlide 3 2 NA January July

Upper and Lower Heads Ref. No 3M Part No Description

Upper and Lower Heads

Upper and Lower Heads Ref. No 3M Part No Description

Upper and Lower Heads AccuGlide 3 2 NA January

Latch Upper and Lower Heads Ref. No 3M Part No Description

Lower Head AccuGlide 3 2 NA January

Lower Head Ref. No 3M Part No Description

Lower Head

Lower Head Ref. No 3M Part No Description

This page is Blank