3DUW1XPEHU $SULO

‹&RS\ULJKW$JLOHQW7HFKQRORJLHV,QF $OO5LJKWV5HVHUYHG

Convenient bench-top features

Flexible system features

Front Panel at a Glance

Page

Front-Panel Voltage and Current Limit Settings

T e

Display Annunciators

OVP

Rear Panel at a Glance

Key to

This Book

Page

Contents

Contents

Remote Interface Reference

Error Messages

General Information

Safety Considerations

Safety and EMC Requirements

General Information Options and Accessories

Options and Accessories

Accessories

Options

Description

General Information Description

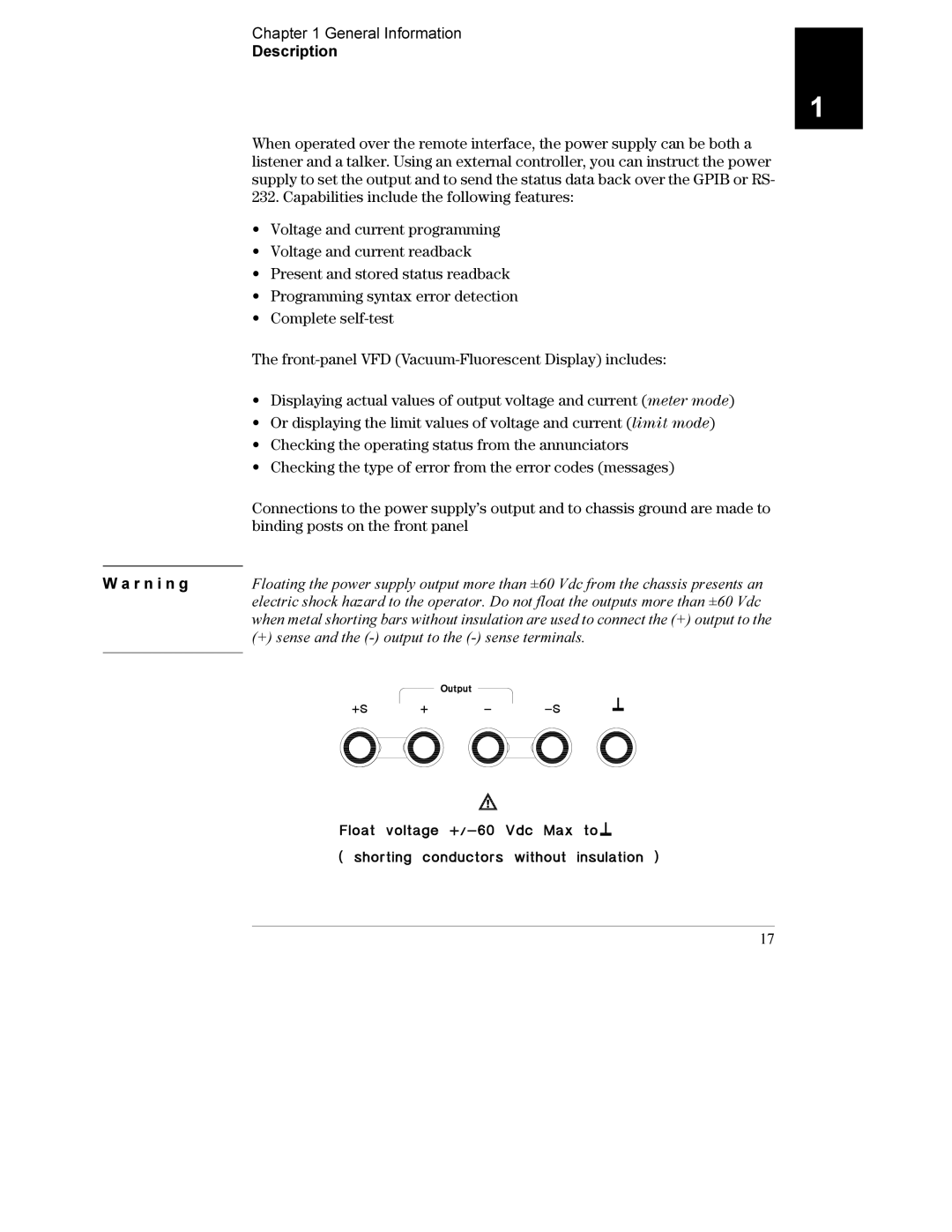

R n i n g

General Information Description R n i n g

Installation

Initial Inspection

Cooling and Location

General Information Installation Rack Mounting

Page

Power-Line Voltage Selection

Input Power Requirements

Power-Line Cord

General Information Input Power Requirements

Power-line module

Panel

General Information Input Power Requirements

Initial Operation

Initial Operation

Connect the power-line cord and turn on your power supply

Verify the power-line voltage setting on the rear panel

Verify that the correct power-line fuse is installed

Preliminary Checkout

Initial Operation Power-On Checkout

Enable the outputs

Addr 05 or RS-232

Output Checkout

Voltage Output Checkout

Initial Operation Output Checkout

Turn on the power supply

Adjust the voltage limit value to 1.0 volt

Current Output Checkout

T e

Initial Operation Output Checkout

Front-Panel Operation

Front-Panel Operation

Front-Panel Operation Overview

Front-Panel Operation Front-Panel Operation Overview

Constant Voltage Operation

Set the display to the limit mode

Adjust the knob for the desired current limit

Front-Panel Operation Constant Voltage Operation

VOLTage voltageMINMAX

Return to the meter mode

CURRent currentMINMAX

OUTPut on

Adjust the knob for the desired voltage limit

Constant Current Operation

Front-Panel Operation Constant Current Operation

Verify that the power supply is in the constant current mode

Storing and Recalling Operating States

Set up the power supply for the desired operating state

Turn on the storage mode

Store the operating state in memory location

SAV

RCL

Setting the OVP Level and Enable the OVP Circuit

Programming Overvoltage Protection

Level 32.0

Checking OVP Operation

Readjust the OVP trip level or the output voltage level

Move to the clear mode Ovp on

Clearing the Overvoltage Condition

Voltprotstat Offon

Clear the overvoltage condition and exit this menu

Voltprot voltageMINMAX

Voltprotcle

Programming Overcurrent Protection

Setting the OCP Level and Enable the OCP Circuit

Enable the OCP circuit

Front-Panel Operation Programming Overcurrent Protection

Checking OCP Operation

Readjust the OCP trip level or the output current level

Move to the clear mode Ocp on

Clearing the Overcurrent Condition

Currprotstat Offon

Clear the overcurrent condition and exit this menu

Currprot currentMINMAX

Currprotcle

Output Rating

Remote Voltage Sensing

CV Regulation

Output Noise

Stability

Remote Voltage Sensing Connections

Disabling the Output

Front-Panel Operation Disabling the Output

Outp Offon

Disabling the Output Using an External Relay

Knob Locking

Front-Panel Operation System-Related Operations

System-Related Operations

Self-Test

TST?

SYSTERR?

Error Conditions

ERR

113, Undefined header

Disptextcle

Display Control

Disp Offon

Disptext ‘HELLO’

IDN? Returns HEWLETT-PACKARD,E3632A,0,X.X-X.X-X.X

Firmware Revision Query

Scpi Language Version

SYSTVERS?

Remote Interface Configuration

Front-Panel Operation Remote Interface Configuration

Remote Interface Selection

Gpib Address

Baud Rate Selection RS-232

Parity Selection RS-232

To Set the Gpib Address

Gpib

Baud

To Set the Baud Rate and Parity RS-232

RS-232

Choose the RS-232 interface

For one second

Gpib Interface Configuration

T e Front-Panel Operation Gpib Interface Configuration

Front-Panel Operation RS-232 Interface Configuration

RS-232 Interface Configuration

RS-232 Configuration Overview

RS-232 Data Frame Format

Connection to a Computer or Terminal

DTR / DSR Handshake Protocol

RS-232 Troubleshooting

Calibration Overview

Calibration Security

Front-Panel Operation Calibration Overview

Code

Calsecstat OFF, HP003632

Calsecstat ON, HP003632

Calsecstat

Calseccode

ZZ001443

ON, ZZ00143

Calibration Count

Calibration Message

Calstr ‘CAL 05-1-97’

Remote Interface Reference

Scpi

Scpi Command Summary

Remote Interface Reference Scpi Command Summary

VOLTageDC?

System-Related Commands

Status Reporting Commands

IEEE-488.2 Common Commands

Simplified Programming Overview

Using the APPLy Command

Using the Low-Level Commands

‘‘VOLT

‘‘SYSTERR?’’

Reading a Query Response

Selecting a Trigger Source

‘‘TRIGSOUR IMM’’

3RZHU6XSSO\3URJUDPPLQJ5DQJHV

APPLy voltage DEF MIN MAX,current DEF MIN MAX

Using the APPLy Command

Remote Interface Reference Using the APPLy Command

APPLy?

Output Setting and Operation Commands

Curr UP

Curr Down

CURRentTRIGgered current MINimum MAXimum

CURRentSTEP numeric valueDEFault

CURRentSTEP? DEFault

CURRentTRIGgered? MINimum MAXimum

CURRentPROTectionSTATe?

CURRentPROTection? MINimumMAXimum

CURRentPROTectionSTATe 01OFFON

CURRentPROTectionTRIPped?

Volt UP

Volt Down

VOLTageTRIGgered? MINimum MAXimum

VOLTageSTEP? DEFault

VOLTageTRIGgered voltage MINimum MAXimum

VOLTagePROTection voltageMINimumMAXimum

VOLTagePROTectionTRIPped?

VOLTagePROTectionSTATe 01OFFON

VOLTagePROTectionSTATe?

VOLTagePROTectionCLEar

MEASureVOLTage?

Trigger Source Choices

Triggering Commands

Remote Interface Reference Triggering Commands

Bus Software Triggering

Immediate Triggering

Trigger 705 group execute trigger

Trigsour BUS*TRG*WAI*TRG*WAI

Trigsour IMM

Triggering Commands

TRG

System-Related Commands

SYSTemERRor?

OUTPutRELay?

SYSTemBEEPer

Curr Currstep

IDN?

HEWLETT-PACKARD,E3632A,0,X.X-X.X-X.X RST

Currtrig Currprot Currprotstat Disp Outp

SAV 1 2

RCL 1 2

Calibration Commands

CALibrationSECureSTATe?

CALibrationSECureCODE new code

CALibrationSECureSTATe OFF ON,code

CALibrationSTRing quoted string

CALibrationVOLTagePROTection

RS-232 Interface Commands

Scpi Status Registers

What is an Event Register?

What is an Enable Register?

Remote Interface Reference Scpi Status Registers

Scpi Status System

101

Questionable Status Event register is cleared when

Questionable Status Enable register is cleared when

Questionable Status Register

102

Standard Event Register

103

Standard Event Enable register is cleared when

Status Byte Register

104

‡ RXHHFXWHWKH*CLSFOHDUVWDWXVFRPPDQG

‡ RXHHFXWHWKH*SRE 0FRPPDQG

Diihfwlqvwuxphqwwkurxjksxw

Using *STB? to Read the Status Byte

Using the Message Available Bit MAV

To Interrupt Your Bus Controller Using SRQ

To Determine When a Command Sequence is Completed

Using *OPC to Signal When Data is in the Output Buffer

107

STATusQUEStionableCONDition?

Status Reporting Commands

Remote Interface Reference Status Reporting Commands

STATusQUEStionable?

ESR?

CLS

ESE?

OPC

STB?

PSC?

SRE?

WAI

An Introduction to the Scpi Language

111

Command Format Used in This Manual

CURRent currentMINimumMAXimumUPDOWN

‘‘SOURceCURRentTRIGgered’’ ‘‘APPLy 3.5,1.5’’ 112

Sourvolt Mincurr MAX

Command Separators

Using the MIN and MAX Parameters

Sourvolt MIN Sourcurr MAX

IEEE-488.2 Common Commands

Querying Parameter Settings

Scpi Command Terminators

‘‘CURR? MAX’’

Trigsour Busimm

Scpi Parameter Types

Curr currentMINMAXUPDOWN

115

Halting an Output in Progress

‡ 7KHSRZHUVXSSO\ªVLQSXWDQGRXWSXWEXIIHUVDUHFOHDUHG

Scpi Conformance Information

RQILUPHG&RPPDQGV

118

SOURce VOLTageLEVelIMMediateAMPLitude voltageMINMAXUPDOWN

HYLFH6SHFLILF&RPPDQGV

IEEE-488 Conformance Information

Error Messages

Error

113, Undefined header 122

Execution Errors

Appl

Example Triggdel

Program mnemonic too long

Undefined header

Invalid character in number

Invalid character data

Block data errors

Expression errors

Character data too long

Too many errors

Settings conflict

CALibrationSTRing command

Data out of range

RS-232 framing error

Isolator Uart framing error

Isolator Uart overrun error

RS-232 overrun error

Self-Test Errors

Calibration Errors

Cal checksum failed, DAC DNL error correction data

Bad DAC DNL error correction data

Cal OVP or OCP status enabled

Bad OVP cal data

Application Programs

132

Diode.c

++ Example for Gpibieee

Application Programs C++ Example for Gpibieee

133

Application Programs ++ Example for Gpibieee

End of Program 134

Excel 5.0 Example for Windows 3.1 and Gpib

135

136

137

Visuccess

End of Program 138

Tutorial

140

Overview of Agilent E3632A Operation

Tutorial Overview of Agilent E3632A Operation

141

142

Output Characteristics

Tutorial Output Characteristics

143

Output Characteristics

144

Unwanted Signals

Unregulated State

145

146

Output Isolation

Connecting the Load

Tutorial Connecting the Load

Multiple Loads

Tutorial Connecting the Load R n i n g

Remote Voltage Sensing

148

Inductive loading

Load Consideration

Capacitive Loading

Pulse Loading

Tutorial Connecting the Load Reverse Current Loading

150

Parallel Connections

Extending the Voltage and Current Range

Series Connections

Tutorial Extending the Voltage and Current Range

Remote Programming

Tutorial Remote Programming

152

153

Speed of Response Programming Down

Reliability

Tutorial Reliability

154

Specifications

156

Performance Specifications

Specifications Performance Specifications

157

158

OCP

Supplemental Characteristics

Specifications Supplemental Characteristics

159

160

Dimensions of Agilent E3632A Power Supply

161

Specifications Supplemental Characteristics 162

Index

163

164

165

166

Warranty

Declaration of Conformity

According to ISO/IEC Guide 22 and EN