MAINTENANCE

MAINTENANCE

DRIVELINE LUBRICATION

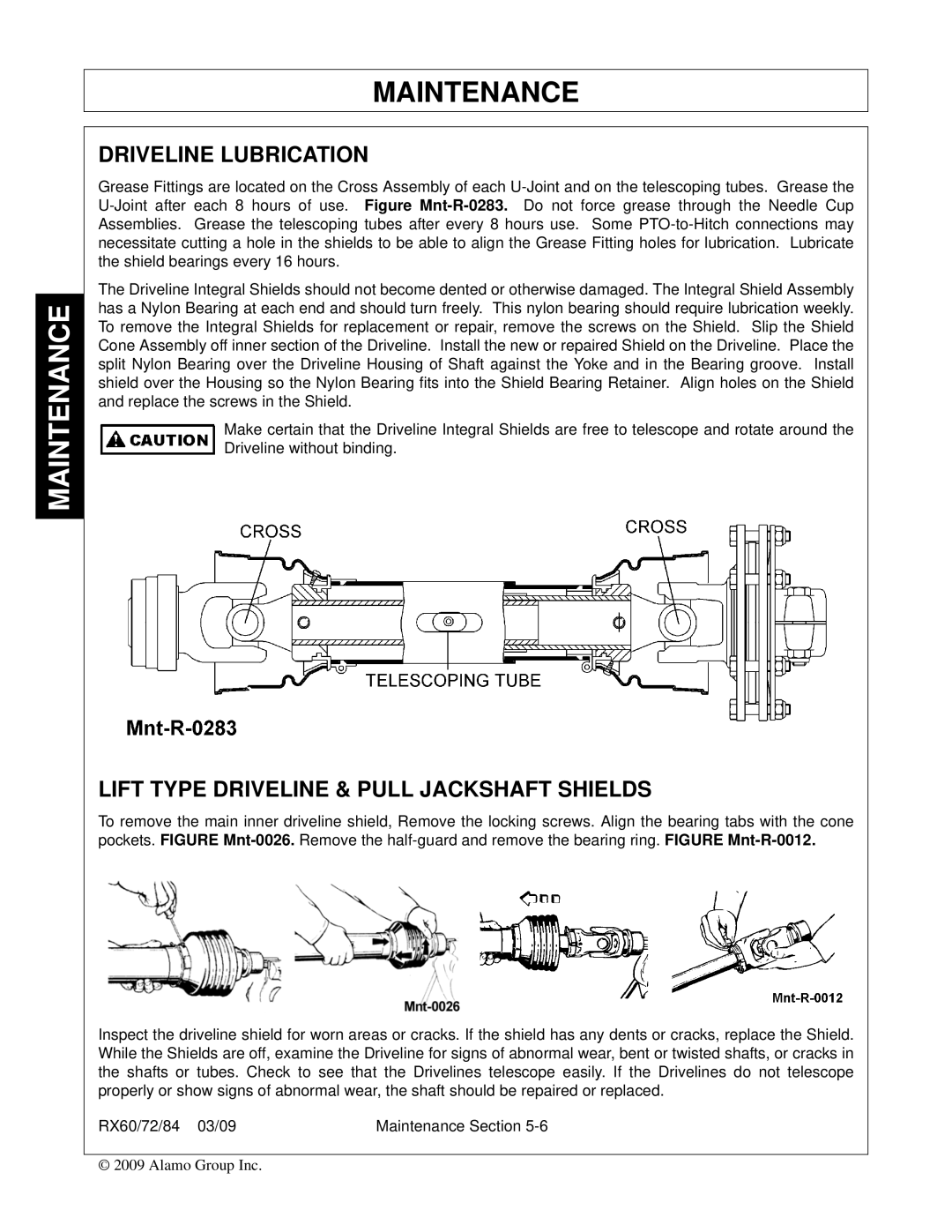

Grease Fittings are located on the Cross Assembly of each

The Driveline Integral Shields should not become dented or otherwise damaged. The Integral Shield Assembly has a Nylon Bearing at each end and should turn freely. This nylon bearing should require lubrication weekly. To remove the Integral Shields for replacement or repair, remove the screws on the Shield. Slip the Shield Cone Assembly off inner section of the Driveline. Install the new or repaired Shield on the Driveline. Place the split Nylon Bearing over the Driveline Housing of Shaft against the Yoke and in the Bearing groove. Install shield over the Housing so the Nylon Bearing fits into the Shield Bearing Retainer. Align holes on the Shield and replace the screws in the Shield.

Make certain that the Driveline Integral Shields are free to telescope and rotate around the Driveline without binding.

LIFT TYPE DRIVELINE & PULL JACKSHAFT SHIELDS

To remove the main inner driveline shield, Remove the locking screws. Align the bearing tabs with the cone pockets. FIGURE

Inspect the driveline shield for worn areas or cracks. If the shield has any dents or cracks, replace the Shield. While the Shields are off, examine the Driveline for signs of abnormal wear, bent or twisted shafts, or cracks in the shafts or tubes. Check to see that the Drivelines telescope easily. If the Drivelines do not telescope properly or show signs of abnormal wear, the shaft should be repaired or replaced.

RX60/72/84 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.