MAINTENANCE

BLADE SERVICING

Inspect blades before each use to determine that they are properly installed and in good condition. Replace any blade that is bent, excessively nicked, worn, or has any other damage. Small nicks can be ground out when sharpening.

Use only original equipment blades on this cutter. They are made of special

BLADE SHARPENING

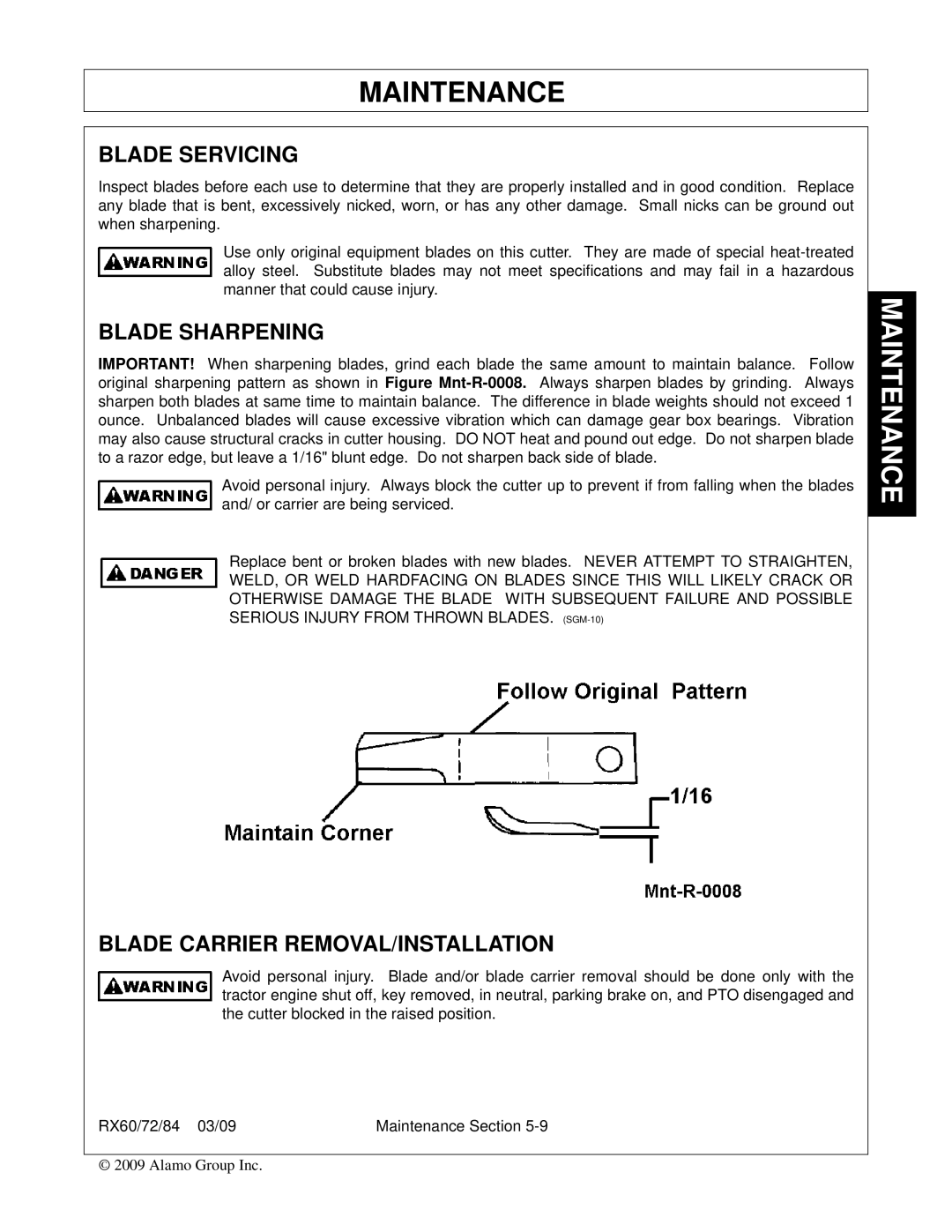

IMPORTANT! When sharpening blades, grind each blade the same amount to maintain balance. Follow original sharpening pattern as shown in Figure

Avoid personal injury. Always block the cutter up to prevent if from falling when the blades and/ or carrier are being serviced.

Replace bent or broken blades with new blades. NEVER ATTEMPT TO STRAIGHTEN, WELD, OR WELD HARDFACING ON BLADES SINCE THIS WILL LIKELY CRACK OR OTHERWISE DAMAGE THE BLADE WITH SUBSEQUENT FAILURE AND POSSIBLE SERIOUS INJURY FROM THROWN BLADES.

BLADE CARRIER REMOVAL/INSTALLATION

Avoid personal injury. Blade and/or blade carrier removal should be done only with the tractor engine shut off, key removed, in neutral, parking brake on, and PTO disengaged and the cutter blocked in the raised position.

RX60/72/84 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.