TROUBLESHOOTING

ELECTRONIC CONTROL MODELS

The remainder of the Troubleshooting section covers Electronic Control Models only.

Fault Conditions

When the control system declares a Fault condition it will display a Fault message on the UIM and lock out. Voltage to the contactor coils and heating elements is terminated to prevent further heating operation.

Alert Conditions

When the control system declares an Alert condition it will continue heating but will display an Alert message on the UIM notifying the user that the water heater requires servicing.

Resetting Control System

Turn the power supply to the water heater off for approximately 20 seconds and then back on. If the operational problem that caused the control system to declare a Fault or Alert condition has not been corrected the control system will continue to display the Alert or Fault message and lock out.

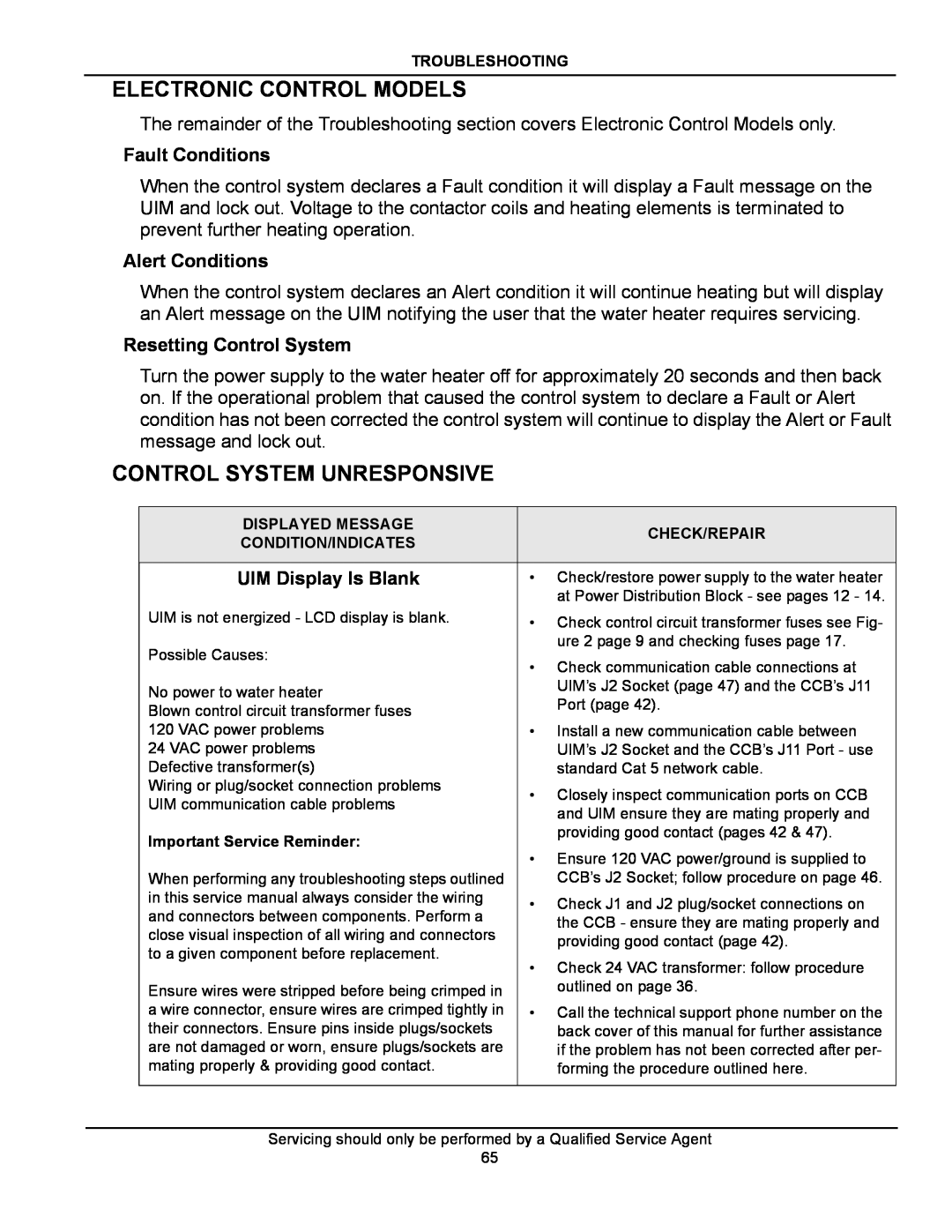

CONTROL SYSTEM UNRESPONSIVE

DISPLAYED MESSAGE | CHECK/REPAIR | |

CONDITION/INDICATES | ||

| ||

|

| |

UIM Display Is Blank | • Check/restore power supply to the water heater | |

| at Power Distribution Block - see pages 12 - 14. | |

UIM is not energized - LCD display is blank. | • Check control circuit transformer fuses see Fig- | |

Possible Causes: | ure 2 page 9 and checking fuses page 17. | |

• Check communication cable connections at | ||

| ||

No power to water heater | UIM’s J2 Socket (page 47) and the CCB’s J11 | |

Port (page 42). | ||

Blown control circuit transformer fuses | ||

| ||

120 VAC power problems | • Install a new communication cable between | |

24 VAC power problems | UIM’s J2 Socket and the CCB’s J11 Port - use | |

Defective transformer(s) | standard Cat 5 network cable. | |

Wiring or plug/socket connection problems | • Closely inspect communication ports on CCB | |

UIM communication cable problems | ||

and UIM ensure they are mating properly and | ||

| ||

Important Service Reminder: | providing good contact (pages 42 & 47). | |

• Ensure 120 VAC power/ground is supplied to | ||

| ||

When performing any troubleshooting steps outlined | CCB’s J2 Socket; follow procedure on page 46. | |

in this service manual always consider the wiring | • Check J1 and J2 plug/socket connections on | |

and connectors between components. Perform a | ||

the CCB - ensure they are mating properly and | ||

close visual inspection of all wiring and connectors | ||

providing good contact (page 42). | ||

to a given component before replacement. | ||

• Check 24 VAC transformer: follow procedure | ||

| ||

Ensure wires were stripped before being crimped in | outlined on page 36. | |

a wire connector, ensure wires are crimped tightly in | • Call the technical support phone number on the | |

their connectors. Ensure pins inside plugs/sockets | back cover of this manual for further assistance | |

are not damaged or worn, ensure plugs/sockets are | if the problem has not been corrected after per- | |

mating properly & providing good contact. | forming the procedure outlined here. | |

|

|

Servicing should only be performed by a Qualified Service Agent

65