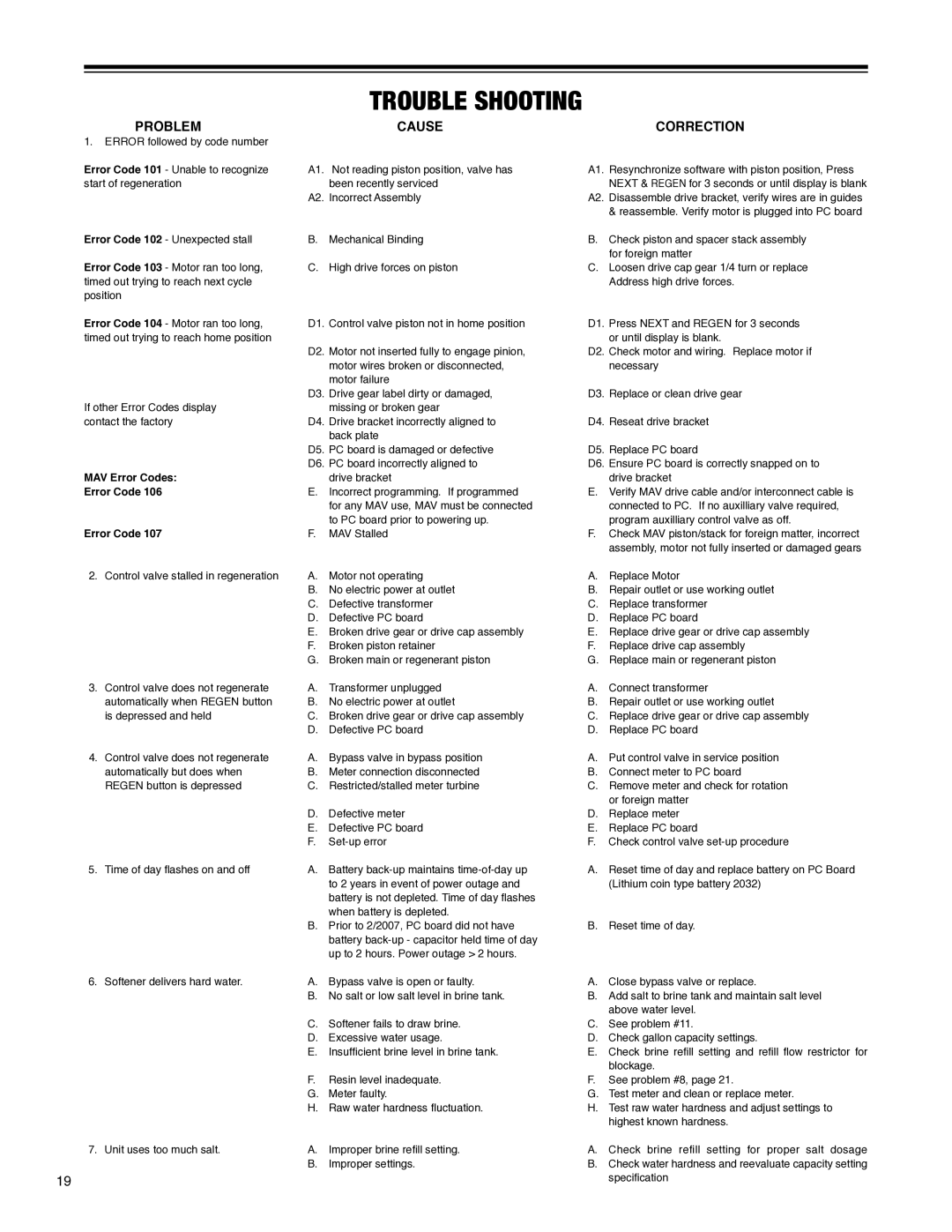

PROBLEM

1.ERROR followed by code number

Trouble Shooting

CAUSE | CORRECTION |

Error Code 101 - Unable to recognize start of regeneration

Error Code 102 - Unexpected stall

Error Code 103 - Motor ran too long, timed out trying to reach next cycle position

Error Code 104 - Motor ran too long, timed out trying to reach home position

If other Error Codes display contact the factory

MAV Error Codes:

Error Code 106

Error Code 107

2.Control valve stalled in regeneration

3.Control valve does not regenerate automatically when REGEN button is depressed and held

4.Control valve does not regenerate automatically but does when REGEN button is depressed

5.Time of day flashes on and off

6.Softener delivers hard water.

7. Unit uses too much salt.

19

A1. Not reading piston position, valve has been recently serviced

A2. Incorrect Assembly

B.Mechanical Binding

C.High drive forces on piston

D1. Control valve piston not in home position

D2. Motor not inserted fully to engage pinion,

motor wires broken or disconnected, motor failure

D3. Drive gear label dirty or damaged, missing or broken gear

D4. Drive bracket incorrectly aligned to back plate

D5. PC board is damaged or defective

D6. PC board incorrectly aligned to drive bracket

E.Incorrect programming. If programmed for any MAV use, MAV must be connected to PC board prior to powering up.

F.MAV Stalled

A.Motor not operating

B.No electric power at outlet

C.Defective transformer

D.Defective PC board

E.Broken drive gear or drive cap assembly

F.Broken piston retainer

G.Broken main or regenerant piston

A.Transformer unplugged

B.No electric power at outlet

C.Broken drive gear or drive cap assembly

D.Defective PC board

A.Bypass valve in bypass position

B.Meter connection disconnected

C.Restricted/stalled meter turbine

D.Defective meter

E.Defective PC board

F.

A.Battery

B.Prior to 2/2007, PC board did not have battery

A.Bypass valve is open or faulty.

B.No salt or low salt level in brine tank.

C.Softener fails to draw brine.

D.Excessive water usage.

E.Insufficient brine level in brine tank.

F.Resin level inadequate.

G.Meter faulty.

H.Raw water hardness fluctuation.

A.Improper brine refill setting.

B.Improper settings.

A1. Resynchronize software with piston position, Press NEXT & REGEN for 3 seconds or until display is blank

A2. Disassemble drive bracket, verify wires are in guides

& reassemble. Verify motor is plugged into PC board

B.Check piston and spacer stack assembly for foreign matter

C.Loosen drive cap gear 1/4 turn or replace Address high drive forces.

D1. Press NEXT and REGEN for 3 seconds or until display is blank.

D2. Check motor and wiring. Replace motor if necessary

D3. Replace or clean drive gear

D4. Reseat drive bracket

D5. Replace PC board

D6. Ensure PC board is correctly snapped on to drive bracket

E.Verify MAV drive cable and/or interconnect cable is connected to PC. If no auxilliary valve required, program auxilliary control valve as off.

F.Check MAV piston/stack for foreign matter, incorrect assembly, motor not fully inserted or damaged gears

A.Replace Motor

B.Repair outlet or use working outlet

C.Replace transformer

D.Replace PC board

E.Replace drive gear or drive cap assembly

F.Replace drive cap assembly

G.Replace main or regenerant piston

A.Connect transformer

B.Repair outlet or use working outlet

C.Replace drive gear or drive cap assembly

D.Replace PC board

A.Put control valve in service position

B.Connect meter to PC board

C.Remove meter and check for rotation or foreign matter

D.Replace meter

E.Replace PC board

F.Check control valve

A.Reset time of day and replace battery on PC Board (Lithium coin type battery 2032)

B.Reset time of day.

A.Close bypass valve or replace.

B.Add salt to brine tank and maintain salt level above water level.

C.See problem #11.

D.Check gallon capacity settings.

E.Check brine refill setting and refill flow restrictor for blockage.

F.See problem #8, page 21.

G.Test meter and clean or replace meter.

H.Test raw water hardness and adjust settings to highest known hardness.

A.Check brine refill setting for proper salt dosage

B.Check water hardness and reevaluate capacity setting specification