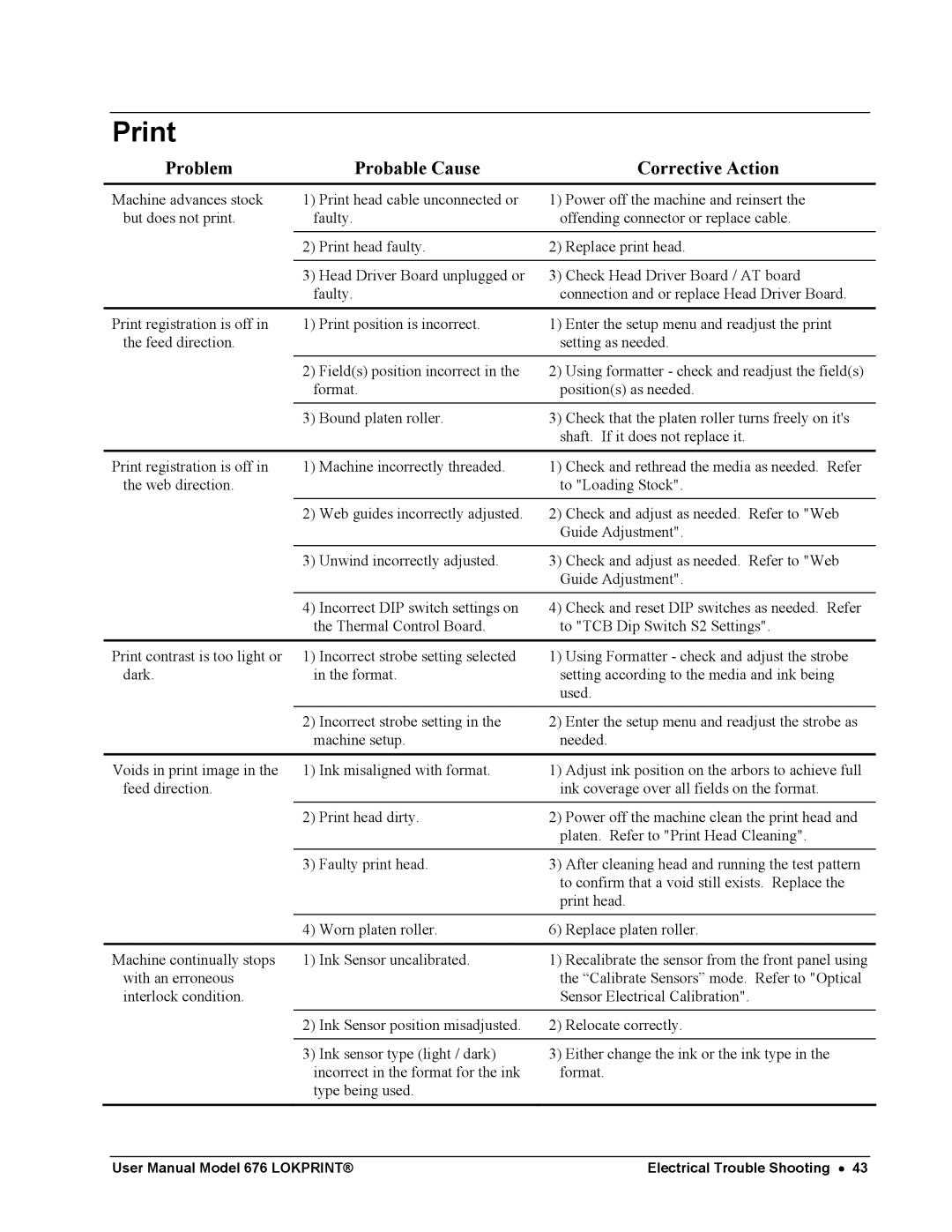

Problem |

| Probable Cause |

| Corrective Action |

|

|

|

| |

Machine advances stock | 1) Print head cable unconnected or | 1) | Power off the machine and reinsert the | |

but does not print. | faulty. | offending connector or replace cable. | ||

|

|

|

|

|

| 2) | Print head faulty. | 2) | Replace print head. |

|

|

|

|

|

| 3) | Head Driver Board unplugged or | 3) | Check Head Driver Board / AT board |

| faulty. | connection and or replace Head Driver Board. | ||

|

|

|

| |

Print registration is off in | 1) Print position is incorrect. | 1) | Enter the setup menu and readjust the print | |

the feed direction. |

|

| setting as needed. | |

|

|

|

|

|

| 2) | Field(s) position incorrect in the | 2) | Using formatter - check and readjust the field(s) |

| format. | position(s) as needed. | ||

|

|

|

|

|

| 3) | Bound platen roller. | 3) | Check that the platen roller turns freely on it's |

|

|

| shaft. If it does not replace it. | |

|

|

|

| |

Print registration is off in | 1) Machine incorrectly threaded. | 1) | Check and rethread the media as needed. Refer | |

the web direction. |

|

| to "Loading Stock". | |

|

|

|

|

|

| 2) | Web guides incorrectly adjusted. | 2) | Check and adjust as needed. Refer to "Web |

|

|

| Guide Adjustment". | |

|

|

|

|

|

| 3) | Unwind incorrectly adjusted. | 3) | Check and adjust as needed. Refer to "Web |

|

|

| Guide Adjustment". | |

|

|

|

|

|

| 4) | Incorrect DIP switch settings on | 4) | Check and reset DIP switches as needed. Refer |

| the Thermal Control Board. | to "TCB Dip Switch S2 Settings". | ||

|

|

|

| |

Print contrast is too light or | 1) Incorrect strobe setting selected | 1) | Using Formatter - check and adjust the strobe | |

dark. | in the format. | setting according to the media and ink being | ||

|

|

| used. | |

|

|

|

|

|

| 2) | Incorrect strobe setting in the | 2) | Enter the setup menu and readjust the strobe as |

| machine setup. | needed. | ||

|

|

|

| |

Voids in print image in the | 1) Ink misaligned with format. | 1) | Adjust ink position on the arbors to achieve full | |

feed direction. |

|

| ink coverage over all fields on the format. | |

|

|

|

|

|

| 2) | Print head dirty. | 2) | Power off the machine clean the print head and |

|

|

| platen. Refer to "Print Head Cleaning". | |

|

|

|

|

|

| 3) | Faulty print head. | 3) | After cleaning head and running the test pattern |

|

|

| to confirm that a void still exists. Replace the | |

|

|

| print head. | |

|

|

|

|

|

| 4) | Worn platen roller. | 6) | Replace platen roller. |

|

|

|

| |

Machine continually stops | 1) Ink Sensor uncalibrated. | 1) | Recalibrate the sensor from the front panel using | |

with an erroneous |

|

| the “Calibrate Sensors” mode. Refer to "Optical | |

interlock condition. |

|

| Sensor Electrical Calibration". | |

|

|

|

|

|

| 2) | Ink Sensor position misadjusted. | 2) | Relocate correctly. |

|

|

|

|

|

| 3) | Ink sensor type (light / dark) | 3) | Either change the ink or the ink type in the |

| incorrect in the format for the ink | format. | ||

| type being used. |

|

| |

|

|

|

|

|

User Manual Model 676 LOKPRINT® | Electrical Trouble Shooting • 43 |