with the outer guide contacting the roll. Turn the knob an additional ½ turn clockwise. This will activate the constant backpressure device.

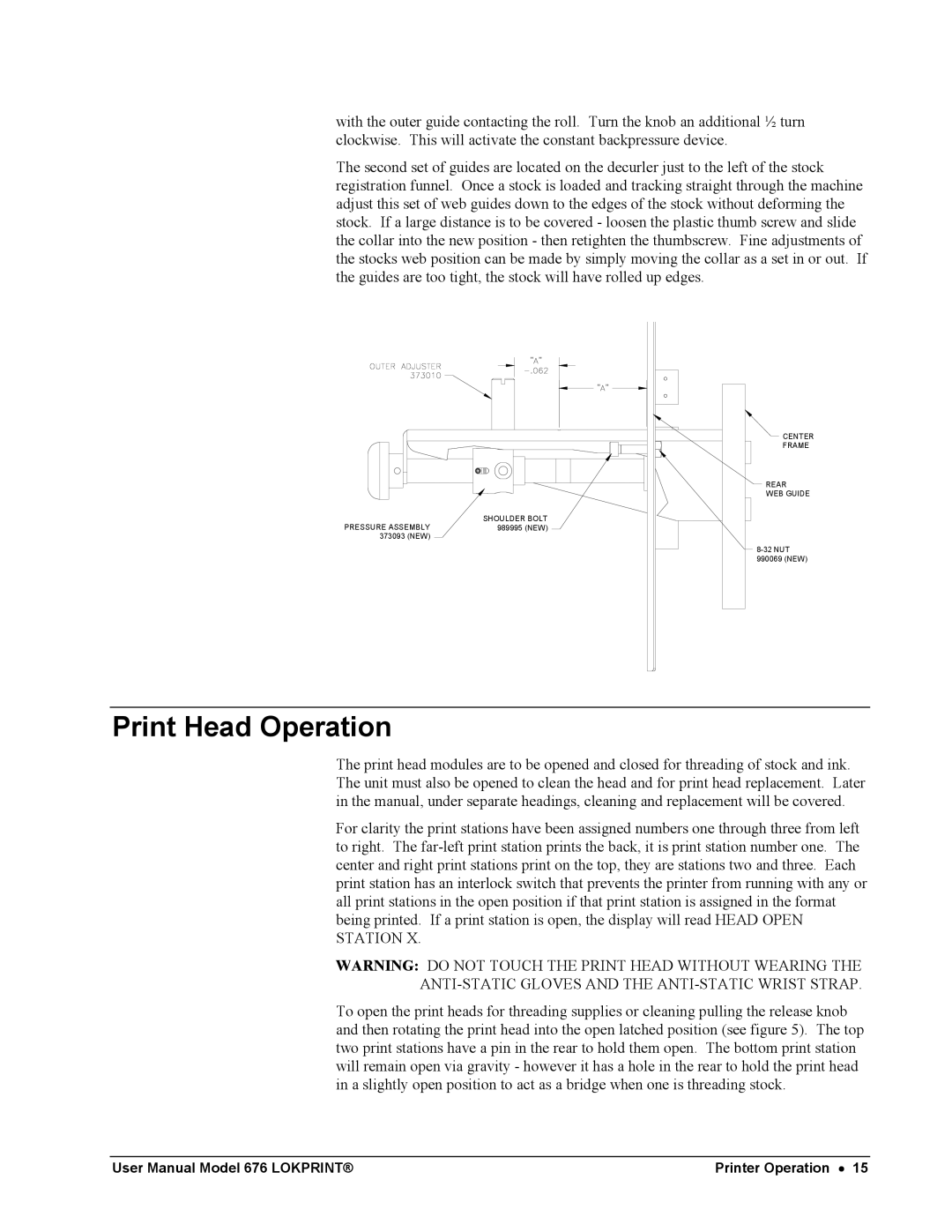

The second set of guides are located on the decurler just to the left of the stock registration funnel. Once a stock is loaded and tracking straight through the machine adjust this set of web guides down to the edges of the stock without deforming the stock. If a large distance is to be covered - loosen the plastic thumb screw and slide the collar into the new position - then retighten the thumbscrew. Fine adjustments of the stocks web position can be made by simply moving the collar as a set in or out. If the guides are too tight, the stock will have rolled up edges.

| SHOULDER BOLT |

PRESSURE ASSEMBLY | 989995 (NEW) |

373093 (NEW) |

|

CENTER

FRAME

REAR

WEB GUIDE

990069 (NEW)

Print Head Operation

The print head modules are to be opened and closed for threading of stock and ink. The unit must also be opened to clean the head and for print head replacement. Later in the manual, under separate headings, cleaning and replacement will be covered.

For clarity the print stations have been assigned numbers one through three from left to right. The

WARNING: DO NOT TOUCH THE PRINT HEAD WITHOUT WEARING THE

ANTI-STATIC GLOVES AND THE ANTI-STATIC WRIST STRAP.

To open the print heads for threading supplies or cleaning pulling the release knob and then rotating the print head into the open latched position (see figure 5). The top two print stations have a pin in the rear to hold them open. The bottom print station will remain open via gravity - however it has a hole in the rear to hold the print head in a slightly open position to act as a bridge when one is threading stock.

User Manual Model 676 LOKPRINT® | Printer Operation • 15 |