DUCT WORK

Any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design airflow requirement of the equipment. Air Conditioning Contractors of America (ACCA) is an excellent guide to proper sizing. All duct work or portions thereof not in the conditioned space should be properly insulated in order to both conserve energy and prevent condensation or moisture damage. When duct runs through unheated spaces, it should be insulated with a minimum of one inch of insulation. Use insulation with a vapor barrier on the outside of the insulation. Flexible joints should be used to connect the duct work to the equipment in order to keep the noise transmission to a minimum.

The

Make sure to seal the slots in the

FIGURE 8

SUPPLY DUCT CONNECTIONS

20" | SUPPLY DUCT AND |

24" | FASTENERS TO BE |

|

FIELD SUPPLIED

BEND THE PROVIDED

SUPPLY FRAME FLANGES

UP FOR DUCT INSTALLATION

afloor mounted install

The unit is equipped with a variable speed indoor blower motor which increases in speed with an increase in duct static pressure. The unit will therefore deliver proper rated airflow up to the maximum ESP shown in Table 1A. However, for quiet operation of the air system, the duct static should be kept as low as practical, within the guidelines of good duct design.

FILTERS

Two

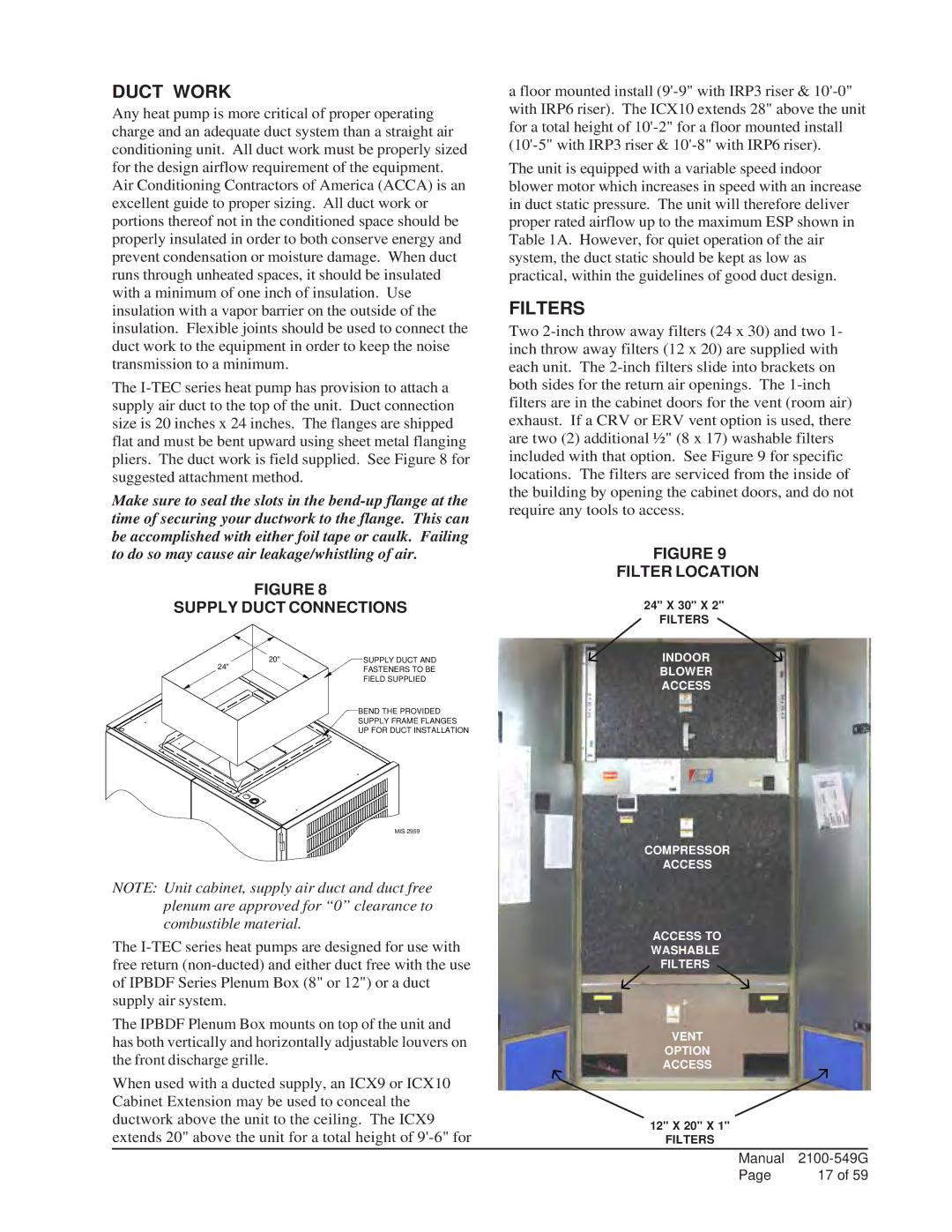

FIGURE 9

FILTER LOCATION

| 24" X 30" X 2" |

|

| FILTERS |

|

É | INDOOR | É |

| BLOWER |

|

| ACCESS |

|

NOTE: Unit cabinet, supply air duct and duct free plenum are approved for “0” clearance to combustible material.

The

The IPBDF Plenum Box mounts on top of the unit and has both vertically and horizontally adjustable louvers on the front discharge grille.

When used with a ducted supply, an ICX9 or ICX10 Cabinet Extension may be used to conceal the ductwork above the unit to the ceiling. The ICX9 extends 20" above the unit for a total height of

É

| COMPRESSOR |

| ACCESS |

| ACCESS TO |

| WASHABLE |

| FILTERS |

É | É |

VENT

OPTION

ACCESS

12" X 20" X 1"

FILTERS

É

Manual | |

Page | 17 of 59 |