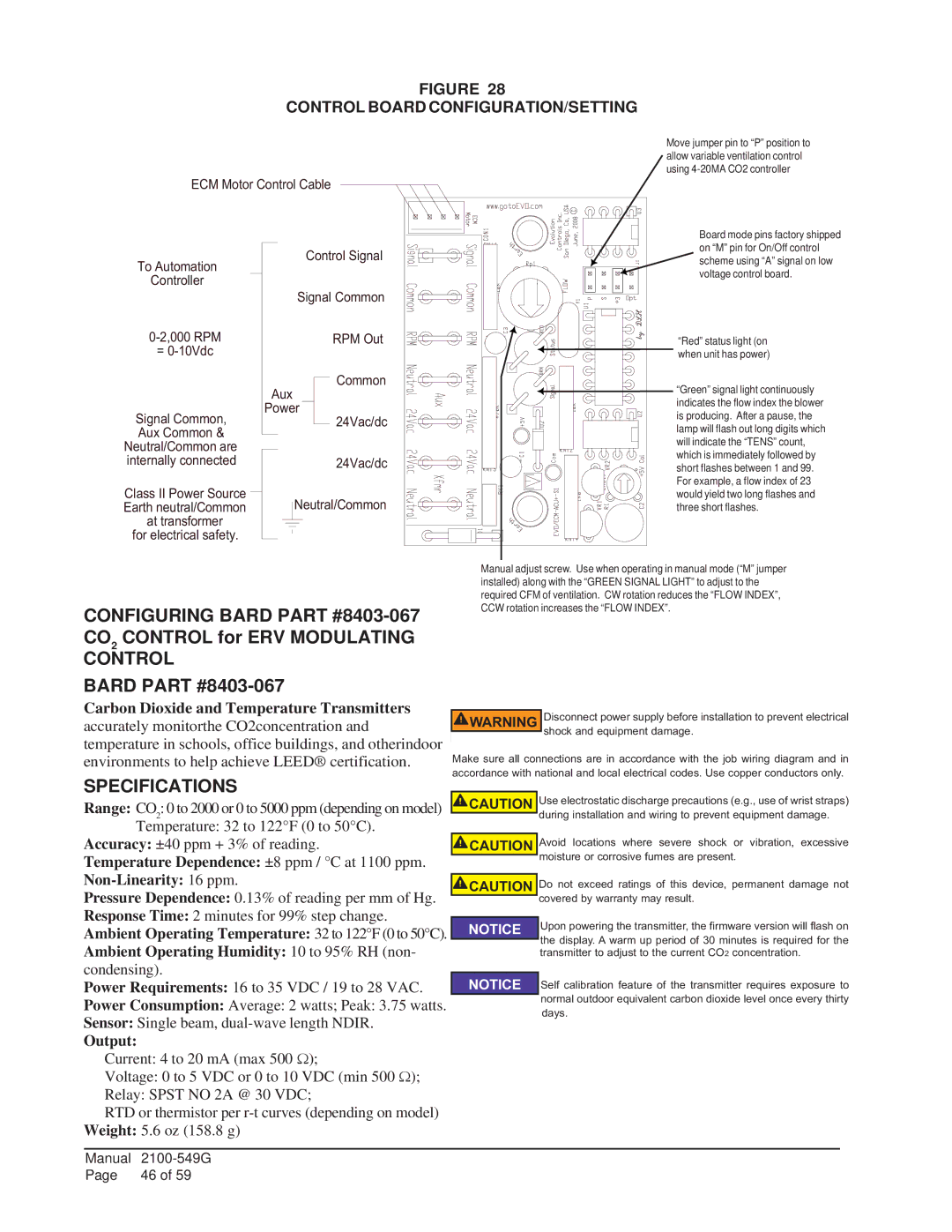

FIGURE 28

CONTROL BOARD CONFIGURATION/SETTING

ECM Motor Control Cable

Move jumper pin to “P” position to allow variable ventilation control using

To Automation

Controller

0-2,000 RPM

= 0-10Vdc

Signal Common, Aux Common & Neutral/Common are internally connected

Class II Power Source Earth neutral/Common at transformer

for electrical safety.

Control Signal

Signal Common

RPM Out

Common

Aux

Power

24Vac/dc

24Vac/dc

Neutral/Common

Board mode pins factory shipped on “M” pin for On/Off control scheme using “A” signal on low voltage control board.

“Red” status light (on when unit has power)

“Green” signal light continuously indicates the flow index the blower is producing. After a pause, the lamp will flash out long digits which will indicate the “TENS” count, which is immediately followed by short flashes between 1 and 99. For example, a flow index of 23 would yield two long flashes and three short flashes.

CONFIGURING BARD PART

BARD PART

Manual adjust screw. Use when operating in manual mode (“M” jumper installed) along with the “GREEN SIGNAL LIGHT” to adjust to the required CFM of ventilation. CW rotation reduces the “FLOW INDEX”, CCW rotation increases the “FLOW INDEX”.

Carbon Dioxide and Temperature Transmitters accurately monitorthe CO2concentration and temperature in schools, office buildings, and otherindoor environments to help achieve LEED® certification.

SPECIFICATIONS

![]() WARNING Disconnect power supply before installation to prevent electrical

WARNING Disconnect power supply before installation to prevent electrical ![]() shock and equipment damage.

shock and equipment damage.

Make sure all connections are in accordance with the job wiring diagram and in accordance with national and local electrical codes. Use copper conductors only.

Range: CO2: 0 to 2000 or 0 to 5000 ppm (depending on model) Temperature: 32 to 122°F (0 to 50°C).

Accuracy: ±40 ppm + 3% of reading.

Temperature Dependence: ±8 ppm / °C at 1100 ppm.

Pressure Dependence: 0.13% of reading per mm of Hg.

Response Time: 2 minutes for 99% step change.

![]()

![]() CAUTION

CAUTION

![]()

![]() CAUTION

CAUTION

![]()

![]() CAUTION

CAUTION

Use electrostatic discharge precautions (e.g., use of wrist straps) during installation and wiring to prevent equipment damage.

Avoid locations where severe shock or vibration, excessive moisture or corrosive fumes are present.

Do not exceed ratings of this device, permanent damage not covered by warranty may result.

Ambient Operating Temperature: 32 to 122°F (0 to 50°C).

Ambient Operating Humidity: 10 to 95% RH (non- condensing).

Power Requirements: 16 to 35 VDC / 19 to 28 VAC.

Power Consumption: Average: 2 watts; Peak: 3.75 watts.

Sensor: Single beam,

Output:

Current: 4 to 20 mA (max 500 Ω);

Voltage: 0 to 5 VDC or 0 to 10 VDC (min 500 Ω);

Relay: SPST NO 2A @ 30 VDC;

RTD or thermistor per

NOTICE | Upon powering the transmitter, the firmware version will flash on | |

the display. A warm up period of 30 minutes is required for the | ||

| ||

| transmitter to adjust to the current CO2 concentration. |

NOTICE Self calibration feature of the transmitter requires exposure to normal outdoor equivalent carbon dioxide level once every thirty days.

Manual | |

Page | 46 of 59 |