SHIPPING DAMAGE

Upon receipt of equipment, the unit should be checked for external signs of shipping damage. The skid must remain attached until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent.

UNIT REMOVAL FROM SKID

![]() WARNING

WARNING

This unit is heavy and requires more than one person to handle during installation and removal from the skid. Extreme caution must be taken to prevent injury to personnel and damage to the unit. Use appropriate safety equipment, including gloves when handling. Failure to do so may result in serious injury.

A forklift or a lift rated for the load (Figure 2A) is required to lift the unit off from the skid. This unit is top heavy and should never be tipped while moving it.

The

Tip unit from left side only.

Failure to do so may result in injury due to unit

FIGURE 2A — UNIT ON LIFT

HANDLING UNIT AFTER REMOVAL FROM SKID

If a wide and tall enough opening exists, the

1.Depress & release both top & bottom door latches and open doors.

2.Remove the doors by lifting straight up and off from the hinge pins.

3.Remove cabinet sides by first removing the four (4) sheet metal screws from the front (leading edge) of the side panel. The panel will not fall off. Swing the panel away from the chassis 20 to 30 degrees & then pull forward from the two (2) tabs supporting the rear edge.

4.On each side of the unit is a tie plate that secures the top and bottom sections with four (4) cap bolts. Using a ½ inch wrench or socket, remove these screws from both plates and set aside.

5.If the unit is equipped with a CRV or ERV, you must unplug the wire harness on the

6.A forklift or a lift rated for the load is required to lift the top section off from the bottom base. Do not attempt to do this manually. Failure to do so could result in the unit tipping over & causing bodily injury and/or damage to the unit.

7.The top section can be forked from either the RH or LH side. See Figure 1 for fork openings.

8.Carefully lift the top section straight up avoiding tipping.

9.Move the top section through the doorway and place on flat surface free of debris.

10.The bottom base can now be moved through the doorway the same way.

11.Reassemble the unit by reversing this procedure.

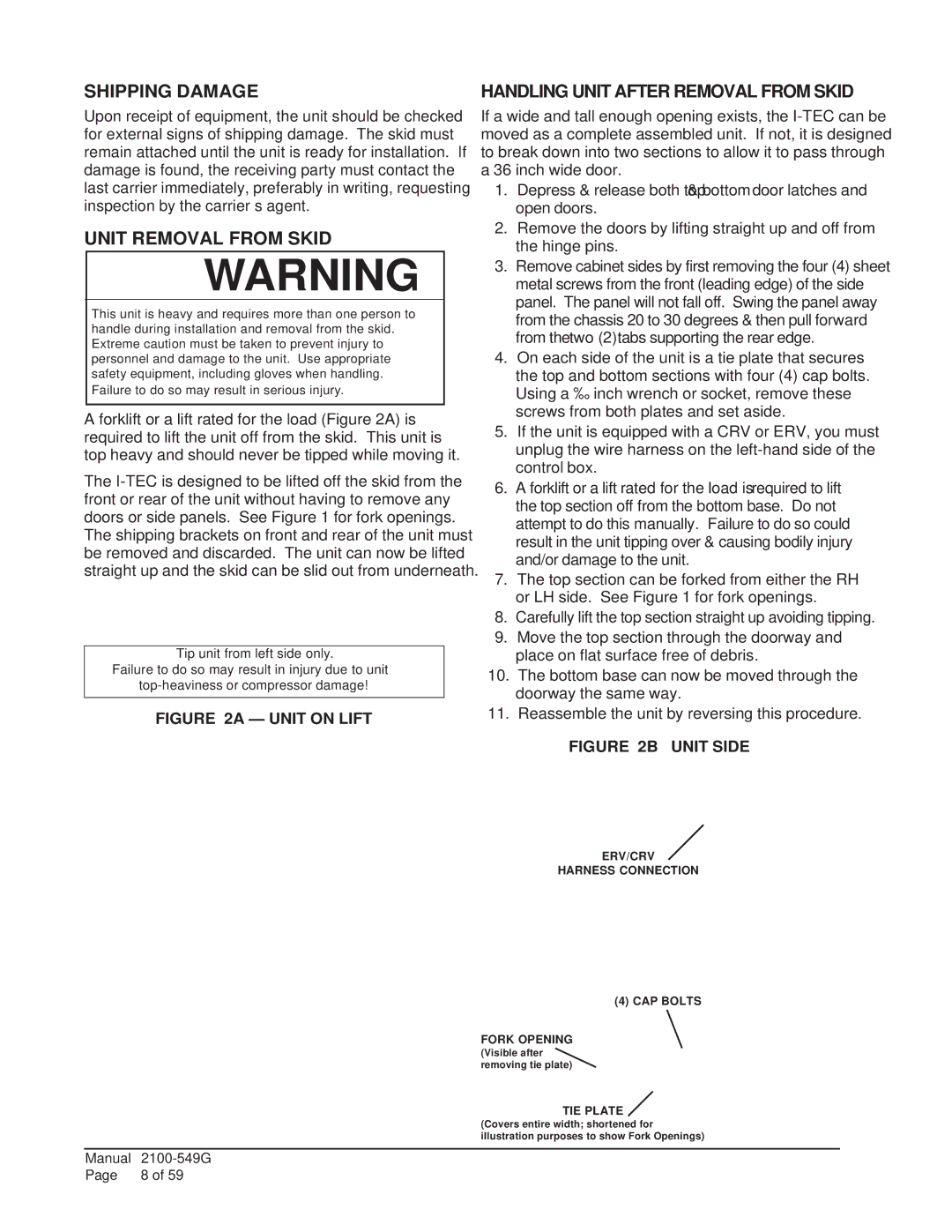

FIGURE 2B UNIT SIDE

É

ERV/CRV

HARNESS CONNECTION

| (4) CAP BOLTS | |

FORK OPENING | É | |

(Visible after | ||

| ||

removing tie plate) | É | |

| É |

TIE PLATE

(Covers entire width; shortened for illustration purposes to show Fork Openings)

Manual | |

Page | 8 of 59 |